Corrdesa (Tyrone, Georgia, USA) is now under contract to supply an initial 50 Dalistick units, with options for more than 40 units per year for the following three years, to equip the growing number of F-35 squadrons around the world.

Corrdesa (Tyrone, Georgia, USA) is now under contract to supply an initial 50 Dalistick units, with options for more than 40 units per year for the following three years, to equip the growing number of F-35 squadrons around the world.

The Dalistick plating/anodizing unit is designed as a closed-loop system that pumps electrolyte from the bottle, through the plating tool where it repairs the aircraft, and back into the bottle for clean, no-touch disposal when it is depleted. The operator only needs to clean, smooth, and measure the area to be repaired; glide the plating tool over the damaged area until the machine shuts off at the predetermined plating thickness; and apply a non-chromate passivate. The aircraft can then be non-chrome primed and painted before it is put back in the air.

Lockheed Martin’s fifth-generation F-35 is not only considered the most advanced fighter aircraft in the world, but also the greenest. It is designed and produced with mission readiness and the warfighter's success in mind—at the same time, almost all cadmium, chromates, and other toxic materials have been eliminated from construction and maintenance.

Toxic chromated cadmium for corrosion control has been replaced by clean, safe, and more effective chromate-free electroplated zinc nickel (ZnNi). For new builds, this is done in large, commercial electroplating tanks. But when the coatings are damaged in the field, on-aircraft repair is required for a quick turnaround without substantial disassembly.

Over the past seven years, Department of Defense funding from the Small Business Innovation Research (SBIR) program, the Strategic Environmental Research and Development Program (SERDP), and the Environmental Security Technology Certification Program (ESTCP) has helped Corrdesa to develop and qualify non-drip brush plating and anodizing repair processes, equipment and tooling. Partnering with DALIC (Vitré, France), the Dalistick non-drip brush plating equipment has been tested and further developed to address repair challenges in the United States Air Force (USAF), US Navy maintenance facilities, and aircraft carriers, which require safe operation on deck at sea.

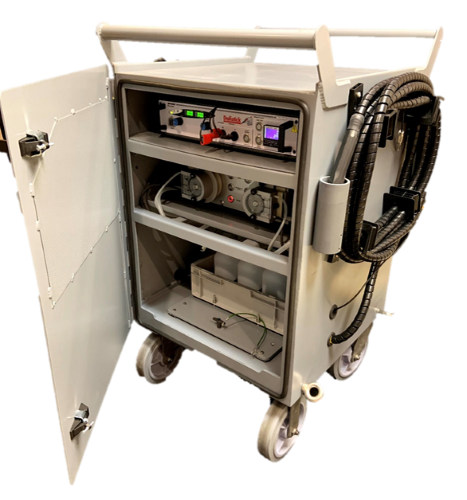

Brush plating is typically done in a hangar, where drips and spills of plating chemicals can be controlled, channeled, or at least wiped up to avoid exposing workers to harmful chemicals. But brush plating outside on the flight line or a pitching carrier deck is an entirely different proposition. For that the F-35 ground support equipment (GSE) plating systems are installed in custom-designed ruggedized carts, enabling repair directly on the aircraft in harsh conditions. Being able to repair the aircraft with non-drip, no-mess technology saves time and returns it to service as fast as possible.

Source: Corrdesa, www.corrdesa.com.