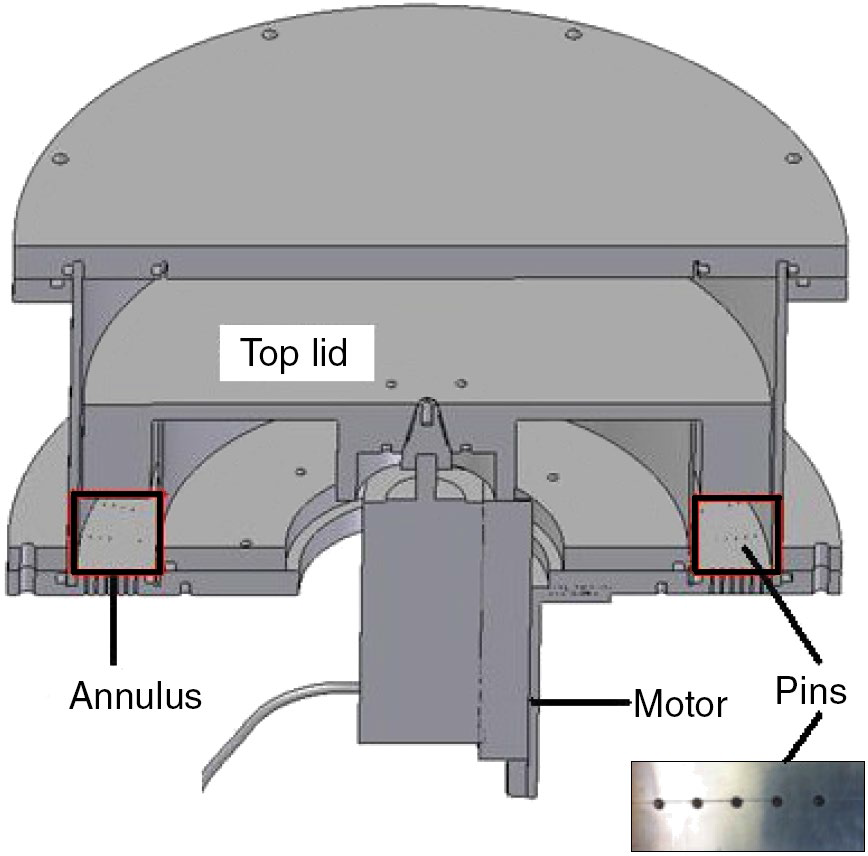

Work by a team researchers with the Institute for Corrosion and Multiphase Technology at Ohio University (Athens, Ohio) may help simplify the process of selecting and qualifying corrosion inhibitors to protect oilfield pipelines from internal corrosion. Carbon steel (CS), widely used by the oil and gas industry for pipelines, freely corrodes when it comes into contact with water that is produced along with crude oil and natural gas from underground reservoirs. Crude oil, in contrast, isn’t corrosive to pipelines in upstream production environments. Research on corrosion inhibitors, which are injected into a pipeline to mitigate internal corrosion, typically focused almost exclusively on the water phase while essentially overlooking the crude oil phase. But now, the Ohio University team is studying the effects of corrosion inhibitors performance in the crude oil phase. While they are relying on common techniques for their investigation, the researchers created a "doughnut cell," a device designed specifically to measure wettability of the steel surface by simulating oil-water pipe flow on a small scale. Conceptually similar to a carousel, the doughnut cell can determine the occurrence of oil vs. water wetting at the bottom of a pipe, and also can be used to measure corrosion rates. Oil and water are introduced into the cell, and the top lid is rotated to induce flow. A series of conductivity pins flush-mounted at the bottom of the channel detect whether water or oil is wetting the bottom. The corrosion testing cell generates data about the corrosion rate of CS with different testing fluids (e.g., water without corrosion inhibitor, water with corrosion inhibitor, and water with a layer of crude oil and corrosion inhibitor). The researchers found that beyond lowering the corrosion rate, corrosion inhibitors can increase the oil wettability of steel, making it more difficult for water to come into direct contact with the steel, while also making it easier for water to be dispersed and flow as droplets within the oil rather than flowing as a separate phase along the surface of the pipe. By reducing the time and costs associated with inhibitor qualification, the team expects the work will simplify the process of selecting, qualifying, and optimizing corrosion inhibitors to protect oilfield pipelines from internal corrosion. To learn more, read the Corrosion paper, "How Do Inhibitors Mitigate Corrosion in Oil-Water Two-Phase Flow beyond Lowering the Corrosion Rate?” by C. Li, S. Richter, and S. Nešic at dx.doi.org/10.5006/1057.

Work by a team researchers with the Institute for Corrosion and Multiphase Technology at Ohio University (Athens, Ohio) may help simplify the process of selecting and qualifying corrosion inhibitors to protect oilfield pipelines from internal corrosion. Carbon steel (CS), widely used by the oil and gas industry for pipelines, freely corrodes when it comes into contact with water that is produced along with crude oil and natural gas from underground reservoirs. Crude oil, in contrast, isn’t corrosive to pipelines in upstream production environments. Research on corrosion inhibitors, which are injected into a pipeline to mitigate internal corrosion, typically focused almost exclusively on the water phase while essentially overlooking the crude oil phase. But now, the Ohio University team is studying the effects of corrosion inhibitors performance in the crude oil phase. While they are relying on common techniques for their investigation, the researchers created a "doughnut cell," a device designed specifically to measure wettability of the steel surface by simulating oil-water pipe flow on a small scale. Conceptually similar to a carousel, the doughnut cell can determine the occurrence of oil vs. water wetting at the bottom of a pipe, and also can be used to measure corrosion rates. Oil and water are introduced into the cell, and the top lid is rotated to induce flow. A series of conductivity pins flush-mounted at the bottom of the channel detect whether water or oil is wetting the bottom. The corrosion testing cell generates data about the corrosion rate of CS with different testing fluids (e.g., water without corrosion inhibitor, water with corrosion inhibitor, and water with a layer of crude oil and corrosion inhibitor). The researchers found that beyond lowering the corrosion rate, corrosion inhibitors can increase the oil wettability of steel, making it more difficult for water to come into direct contact with the steel, while also making it easier for water to be dispersed and flow as droplets within the oil rather than flowing as a separate phase along the surface of the pipe. By reducing the time and costs associated with inhibitor qualification, the team expects the work will simplify the process of selecting, qualifying, and optimizing corrosion inhibitors to protect oilfield pipelines from internal corrosion. To learn more, read the Corrosion paper, "How Do Inhibitors Mitigate Corrosion in Oil-Water Two-Phase Flow beyond Lowering the Corrosion Rate?” by C. Li, S. Richter, and S. Nešic at dx.doi.org/10.5006/1057.