When renowned physicist Michio Kaku delivered the keynote address in March at the 2024 AMPP Conference + Expo in New Orleans, Louisiana, USA, he envisioned a future when artificial intelligence and machine learning will guide the coatings and corrosion prevention industry in exciting new ways.

For four researchers in Trondheim, Norway, the future is now.

In their 2024 AMPP paper “Pitting Corrosion Detection by Ultrasound Monitoring,” Magnus Wangensteen, Tonni Franke Johansen, Ali Fatemi, and Erlend Magnus Viggen propose a technique for early-stage pitting detection through machine learning. Wangensteen presented the paper at the AMPP conference alongside other authors in the machine learning realm.

“I definitely think artificial intelligence is relevant for growth monitoring, and that's what we have leveraged on,” Wangensteen says. “Tiny changes in signals are difficult to distinguish using traditional methods. Machine learning and AI can help us to discriminate what is happening within so that we will be able to do more advanced diagnostics.”

The authors explain that pitting corrosion is a localized form of corrosion that can cause cavities and structural failure in metallic materials, adding that it is more challenging to detect and prevent compared to uniform corrosion.

They continue by stating that ultrasound inspection is an established non-destructive testing technique used to detect internal flaws in materials.

Challenges of Pitting Corrosion

Detecting pitting corrosion near the reflective inner surface, they write, is difficult due to interference effects.

General corrosion is easier to detect using standard methods because it is more uniform, Wangensteen says.

“Pitting is trickier, because it's often a very small pinhole that penetrates the metal,” he says. “The reflected signal from that pinhole is hard to detect using traditional methods, but machine learning could actually detect this.”

By capturing multiple ultrasonic traces over time, two-dimensional time-lapse images of ultrasonic reflectivity can be generated and used as input for a neural network trained for pitting diagnostics, they write.

“I’ve been surprised by how well machine-learning methods have been able to extract information about corrosion data,” Johansen says.

The authors explained the challenges in accurately identifying pitting corrosion using ultrasonic inspection as:

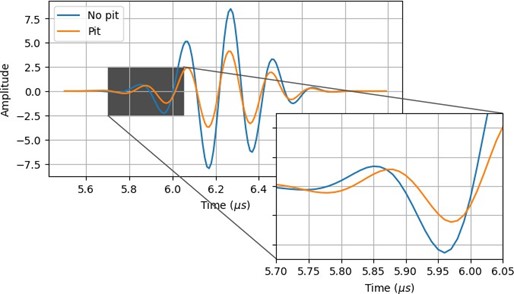

- Reflection difficulties: Because pitting corrosion occurs near the reflective inner interface, it is difficult to separate the reflection of the pit from the inner wall reflection.

- Interference effects: When a small, localized pit scatters back an incoming wave, it can interfere with the main back wall plane wave reflection, resulting in minor errors in wall thickness estimation.

- Undulating reflections: In the early phase of pit development, minor distortions can be imposed on the back wall reflection, giving an undulating impression as the pit is emerging. This could give the misleading impression that the wall thickness is increasing, for example.

Real-World Implications

The same group authored “Ultrasonic Guided Waves and Machine Learning for Corrosion Monitoring in Steel Pipes,” an AMPP 2023 paper based on ultrasound simulations and synthetic data. The 2024 work brings the ultrasound experiment into the real world.

“The challenge with the synthetic experiment has been transferring it to the real world, because you don't control all the parameters in the real world like you're doing in the synthetic world. The paper from this year is much closer to being applicable on real data.”

In the most recent work, they conducted a drilling experiment to obtain a substantial training dataset for the machine learning model.

“The data was combined in a way to produce an almost endless amount of training data,” Wangensteen says. “Individual measurements were combined into a time lapse measurement. You can train a machine learning model and do all the predictions on unseen data.”

While they tried to create pitting through corrosion in a controlled manner, it did not form.

“The next step would be to produce real growth pits and see if the trained neural network could detect them,” Wangensteen says. “That’s the natural next step.”

They hope that in the long term, plant operators can use AI to automate diagnostics and filter out important data.

“AI is able to extract information that is not easily extractable,” Viggen adds. “AI is a very good signal processing tool, which gives plant operators information that they would otherwise not have because that information is hard to get at using other means.”

The Experiment

The researchers used random, time-ordered combinations of pulse-echo measurements to produce time-lapse images. A classification neural network was trained to detect the presence of pits, while a regression network was trained to estimate the pit depth.

Test data from an unseen transducer show that the pit depth estimations had a mean absolute error of less than 0.2 mm. All pits were reliably identified when they exceeded the defined pitting threshold of 0.5 mm by a depth of 0.1 mm, they wrote.

“One very nice thing about machine learning is that with traditional processing methods, you don't always know how to extract information from a given signal,” Viggen says. “You can know that the measurement says something about the state of the system—for example, how corroded the pipe is if there's a pit—but the information might be really hard to get at.

“With AI, if you have enough data where you know the true state of the system, then you can train AI to extract the information for you. And I think this is something that is going to be a very big thing in corrosion monitoring as it’s been in pretty much every other field”

Future Implications

The researchers write that while their study focused on detecting drilled holes, future research could explore the detection and characterization of pits formed by actual corrosion. This would involve training the machine learning model on ultrasound data from real corroded surfaces and developing algorithms to accurately identify and estimate the depth of these irregularly shaped pits.

“AI has given promising results in detecting and characterizing drilled holes in a steel object,” Fatemi says. “We in Sensorlink believe there is great potential in AI when it comes to detecting pitting corrosion and would like to continue developing an AI-based method for this application. We can use AI for much more than pitting detection. We have a great amount of ultrasound data from field installations which we are going to train new AI models on to make our estimations more accurate.”

Timelapse ultrasound monitoring combined with machine learning also could be used to detect other material changes, such as general wall roughness development, scaling formation, embrittlement, and temperature changes. By analyzing the changes in ultrasonic reflectivity over time, it may be possible to identify and quantify these different types of material degradation.

“The good thing with AI is that it can give you answers that wouldn't be possible to find using other means,” Viggen concludes. “This work is a good example of that, where it's difficult to use traditional processing, such as data processing algorithms, to extract that information from the signals that have been measured. Our research has shown that with AI, it works quite well.”

About the Researchers

Wangensteen recently began a position as ultrasound expert with Sensorlink, which delivers high-resolution corrosion and erosion monitoring systems. He has a master’s degree and is pursuing a Ph.D. from the Norwegian University of Science and Technology (NTNU). He worked in oil exploration as a geophysicist for 19 years before moving into using ultrasound for diagnosing the condition of pipes.

At Sensorlink, he works with Fatemi, an ultrasound engineer who earned his Ph.D. from NTNU researching cardiac ultrasound images.

The paper’s other authors are Johansen, a Ph.D. research scientist with research organization SINTEF (The Foundation for Industrial and Technical Research) who has extensive experience in acoustics, and Viggen, who has a Ph.D. in acoustics and previously worked with Johansen at SINTEF before going on to postdoctoral research in ultrasonics at NTNU.

Editor’s note: This article first appeared in the June 2024 print issue of Materials Performance (MP) Magazine. Reprinted with permission.