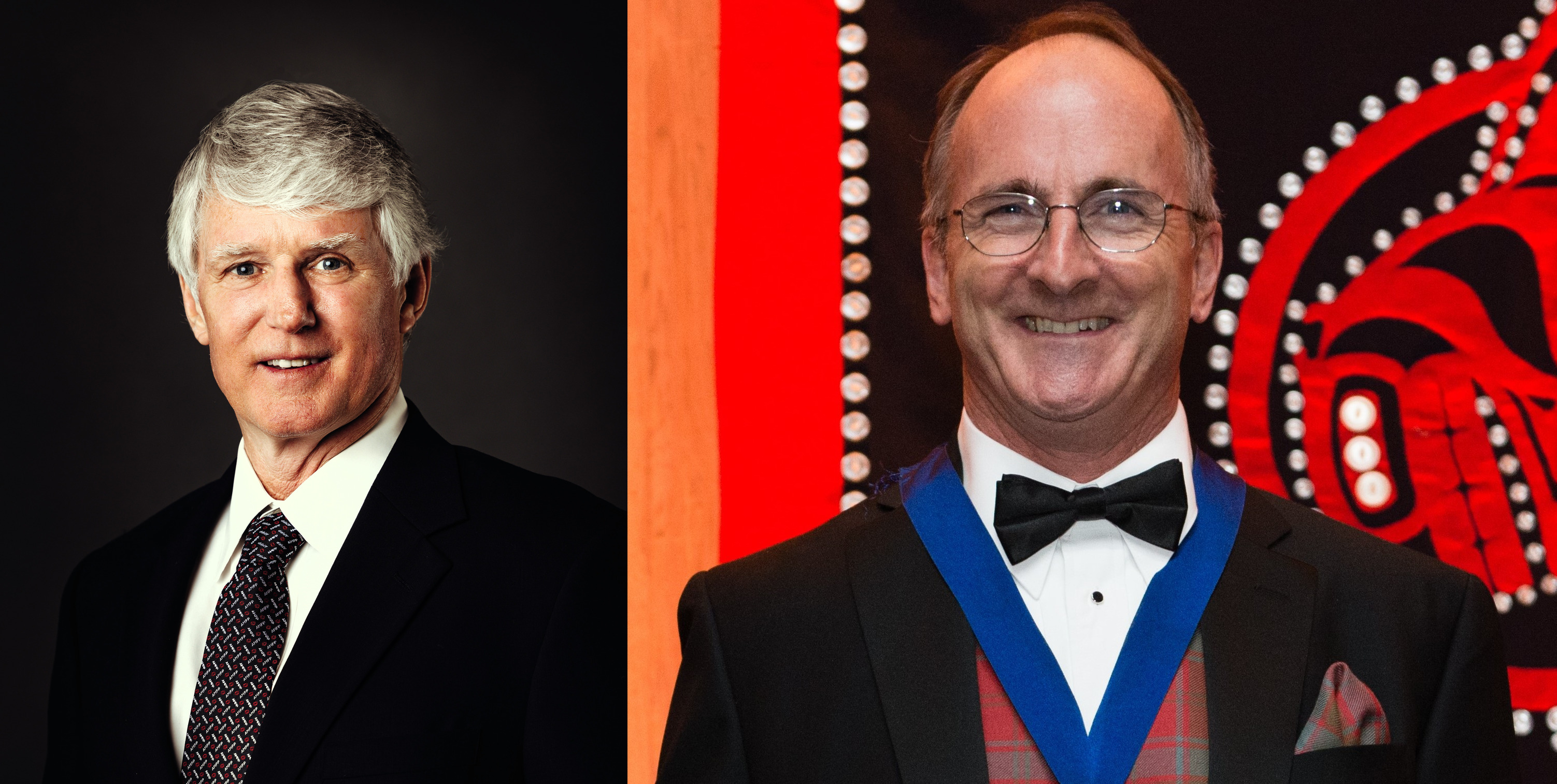

In a panel discussion, AMPP members Cal Chapman (Chapman Engineering) and Sandy Williamson (Williamson Integrity Services) recently joined Materials Performance (MP) Editor Kerry Cole to explain what sustainability means to them and why it is critically important to our industry.

Topics discussed on the podcast include how sustainability is already being practiced and its impact on business; trends and new technologies to watch for; and expectations for the future.

The conversation also explores initiatives and opportunities to get involved at an association level, such as AMPP’s Sustainability Task Force; a technical community of interest (TCI) on materials sustainability; and a Sustainability Symposium and Expert Panel session at the AMPP 2024 Annual Conference + Expo in March.

Read on for a partial transcript of that episode, which can be listened to in its entirety below.

Q: Can each of you introduce yourself to our audience?

Chapman: My name is Cal Chapman, and I have a business called Chapman Engineering Incorporated. We’re based in Texas in the United States. I’m celebrating 35 years of leading this business as of this month, October. I guess I could say I’m very proud of that, and I’ve also proven for one thing that I’m very stubborn.

In the history of Chapman Engineering, I actually started this as an environmental engineering and science company and then transitioned into corrosion control by the mid-1990s. I can tell a couple of stories in a little while about some big environmental efforts I was part of that led me to understand what sustainability means in a number of ways.

Williamson: Yes, my name is Sandy Williamson. I’ve been a member of NACE and AMPP for 43 years. I had the privilege of being president of NACE international back in 2016-17. And I’ve been active in the oil and gas offshore, onshore, downhole, plants, and pipelines, and more recently geothermal and lithium production, which I’m really excited about.

More specific to what we’re going to talk about today, I started a TEG back at the time in NACE, a technical exchange group, in material sustainability quite a few years ago. And we’re going to, as Cal mentioned, we’re going to talk some more details. But I ran a technical program for the Canada Area Conference on material sustainability and the circular economy back in 2019. So, I’ve been quite active in the sustainability space for the last few years.

Q: As we’re talking about sustainability, how do you define sustainability? And in what ways is it affecting business and your segment of the industry? Why is it so important?

Chapman: I’m someone who tries to describe sustainability in several different ways and settings. Because everybody, in whatever their industry or business might be, will define it somewhat differently. To me, sustainability means you’re going to maintain something, so that it has a lot of reliability. That’s something that I, as an engineer, love to talk about. And it also doesn’t cause unintended negative consequences.

Williamson: As corrosion practitioners and professionals, we really are part of the sustainability space already. But I want to cite the definition that was brought up by the Brundtland Commission back in 1987 to the United Nations, because I think it still is relevant even though it’s talking about sustainability in a broader sense: “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

And that’s really what we’re trying to strive for, and in particular within AMPP, to focus on the use of materials in protecting them through corrosion management and so on.

As far as ways that it’s affecting our industry, I think most companies today are actively discussing ways that they can make their operations more sustainable. I think everybody recognizes that. And there’s a growing recognition that following sustainable practices has a significant return to their economic bottom line, which is really important for any company that’s in business.

Q: With AMPP, we have the AMPP Sustainability Task Force and other initiatives coming down the pike. There’s a sustainability symposium, an expert panel session at the AMPP 2024 conference. What else do you know that is being done at an association level to help with this initiative?

Williamson: This goes back to my time on the board. The AMPP board has clearly recognized sustainability in their mission. And as you mentioned, they’ve now formed a task force to regularly report back to them. What’s going on in the association? What are the different activities? And are we furthering that mission?

I have the privilege of chairing the symposium coming up in New Orleans at the annual conference, where we’re going to have a half day on material sustainability. ’’’We wanted to have the opportunity to bring in a number of industry leaders and association leaders for a forum and panel in the afternoon. So, we’re going to make it what I might call a sustainability day on the Monday at New Orleans.

We will have a two-hour panel in the afternoon. It will kick with Hongwei Wang, who’s been leading the writing of SP 21 466, which is a standard on materials sustainability. And we, I think, are producing a standard in very good time. It should be finished by this year, with the plan that we can actually have it out and circulated… and let Hongwei introduce that as part of the panel. I think that really will show those attendees how AMPP has embraced sustainability.

But then again, as part of a panel, we’ll be bringing in speakers from around the world to chat about what sustainability means to them, and then still leave an hour for discussion. So, we have lots of activities planned. And I think it’s going to be front row and center at the conference in New Orleans.

Chapman: I will be a player in that Monday, March 4 morning sustainability session in New Orleans… with a presentation about cathodic protection on metal assets submerged or underground. That is a sustainability practice when it’s done properly.

I’ve been working with the Materials Performance (MP) Magazine staff on many things over the years. My tendency is to tell stories, and studies, of basically how not to do things. Let’s look at the ways people have done things incorrectly.

Let’s also look at ways that budgets have been wasted. If you’re wasting your budget, that is not a sustainable practice. Once you make your budget, get your work done cost-effectively. You’re not going to get the second amount of money to redo what the first amount was supposed to do. And yet, I see this happen, time and time again. If you’re going to let somebody waste your money, that’s not a sustainable practice.

For me, it’s about the lessons learned, and the case studies showing people some better practices to incorporate. That’s really, really important. If a company is going to teach sustainability practices within its own organization, it has to drive that teaching all the way out to people in the field. It’s one thing to talk about it, but you’re not going to get it practiced unless it’s involving their boots on the ground.

Q: So, as we have discussed, Materials Performance is starting a new Sustainability Corner. I wonder, in addition to that, as an association publication, what can or should MP do to help with the mission of sustainability?

Chapman: I’ve worked with many people within NACE management, and now AMPP, for the last few years. NACE and SSPC, with whom we’ve now combined to be AMPP, these are organizations that were practicing sustainability in the 1940s and 1950s.

It began in North America, but then spread around the world. Many of the things we have done as this big organization drive sustainability processes. But I don’t think we’ve talked about it in that kind of language, historically.

So, one of the things I’ve done recently — as part of the presentation that will go forward in New Orleans — is to look at things like the NACE IMPACT study that was published in 2016. That study described, very well, how investing in asset sustainability can give return on those investments.

We obviously don’t put a pipeline in the ground or build a big bulk storage tank for potable water, or oil or refined products… and expect to give up on it in 10 or 15 years. We have to build those with good design, good construction, and then maintain those assets to get long, safe service lives. That is all a sustainability process.

Williamson: I think really our mission right now is to allow more and more of our members, through our publication, to understand what this word sustainability really means.

I think one of the most effective ways is to have regular case histories whether it’s the cathodic protection sector, whether it’s the coating sector, whether it’s in the steel industry, whether it’s in pipelines. We’ve included what we can in the in the back end of the standards that we’re going to publish to help people say, “Oh, that’s my industry. That’s something I’m familiar with.”

I think the light bulbs will start to come on as they see something more specific being talked about in their industry. So, I love the idea of having that Sustainability Corner, a regular article.

Chapman: I was sitting with MP staff in Houston, just a few months ago, to talk about the new “Sustainability Corner” in the magazine. I asked the staff people, “Let’s go through the articles you have in your last three months. How many of these do not have something that is sustainability related?” It was a very small number.

In other words, we are already talking about sustainability and sustainable practices, with case studies showing why someone should have done it differently. We just have to change the language we present… to get people more aware.

Editor’s note: The complete episode can be listened to below.