There seems to be a trend for bridge owners to believe that applying all three coats of paint in the shop is more cost-effective and will provide for a better coatings job on new steel. This article discusses the differences between shop coating and field painting and the pros and cons of shop-applied coatings vs. field-applied coatings on new steel.

This article discusses various cost differences between shop and field painting as it pertains to new steel, and we will cover two case histories of Maryland State Highway Administration jobs that had all three coats of paint applied in the shop.

Shop Painting vs. Field Painting

We will be talking about the most widely used coating system coming out of the shop for bridge coatings, which is an inorganic zinc rich primer followed by an epoxy intermediate and polyurethane topcoat.

There are three combinations of shop and field painting:

- Shop/Shop/Shop (with field touch-up)

- Shop/Shop/Field

- Shop/Field/Field

Shop/Shop/Shop

- All three coats of the specified system are applied in the shop.

- The only field work is the repair of the damaged coating.

Shop/Shop/Field

- The primer and intermediate coats are applied in the shop.

- The finish coat is applied in the field after the repair of any damaged coatings and the removal of surface contaminants.

- Additional surface preparation may be needed to ensure finish coat adhesion or if the re-coat window has been exceeded.

Shop/Field/Field

- This is the most prevalent method.

- Only the primer coat is applied in the shop.

- The intermediate and finish coats are applied in the field after any damaged areas of the primer have been repaired and surface contaminants have been removed.

- Usually, the damaged inorganic zinc primer is touched up with an organic zinc primer.

- Additional surface preparation may be needed to ensure intermediate and finish coat adhesion if contaminants are found or the re-coat window has been exceeded on the intermediate coat.

Pros of Shop Cleaning and Painting

- More easily controlled atmosphere.

- Safer.

- Less contamination of blast-cleaned steel and painted surfaces (Figure 1)

- Less chance of other trades interfering with paint work.

- Work is usually more consistent, so the labor is more consistent, leading to better quality and a more consistent cost of labor.

- Easier containment of blast media and paint overspray.

- Easier access to perform cleaning, painting, and inspection, as most work is done on ground.

- Recycling of materials is easier at a shop facility.

Cons of Shop Cleaning and Painting

- Coatings can be damaged in shop during handling as well as in shipment and during construction (Figures 2 and 3).

- Environmental regulations are more stringent for fixed work sites than construction sites.

- Storage of painted steel members is limited due to space limitations.

- Special masking must be done on faying surfaces (Figure 4).

- Applying an additional coat of finish may be needed on the fascia to give a uniform appearance after erection is complete (Figure 5).

- Most fabricators do not like applying all three coats of paint. They would rather apply zinc-rich primers and then ship it.

Pros of Field Cleaning and Painting

- Coating not normally damaged during shipment.

- No special handling or care techniques needed.

- Zinc-rich primer coating damage during construction is easily repaired using an epoxy zinc coating with some minimal preparation work.

- Finish coat is smooth and free of touchup marks. Two continuous full depth coats are being applied vs. touch up coats, feathering, etc.

Cons of Field Cleaning and Painting

- Controlled environment may be expensive on construction sites.

- Less accessible.

- Greater possibility for contamination of cleaned surfaces and uncured coatings.

- May have conflicts with other trades.

- Complex containment systems.

Field Painting Costs (New Steel)

On average, the cost for applying two coats of paint in the field ranges from $5 to $6 per square foot(1) and consists of cleaning the zinc-primed steel, touching it up with an organic zinc primer, then applying a full coat of epoxy intermediate, and full coat of polyurethane finish. Also included are two stripe coats and access to the area as well as all material costs. Work zone traffic control is usually provided by the general contractor, but may be done by the painting contractor on certain occasions.

Shop Painting Costs

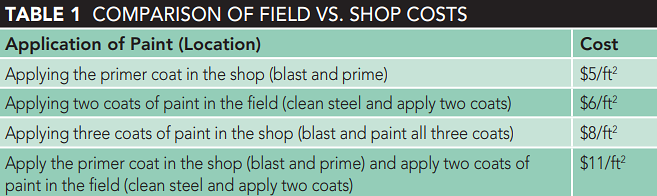

A comparison of field vs. shop coating costs is given in Table 1. On average, the cost for applying the primer coat in the shop is approximately $5 per square foot and consists of blast-cleaning the steel and applying a full coat of inorganic zinc primer. On average, the cost for applying all three coats of paint in the shop is approximately $7 to $8 per square foot and consists of blast cleaning the steel and applying a full coat of inorganic zinc, then applying a full coat of epoxy intermediate and a full coat of polyurethane finish.

Therefore, the main cost difference between the shop and field painting of the intermediate and topcoats is that the cost for shop painting is $3 per square foot less, based solely on square footage estimates.

However, we must consider the areas that must be painted in the field on shop-coated steel, and this is where the price for all three coats of paint increase. We must factor in painting all the faying surfaces, bolt patterns, and fascia surfaces, and touching up all the areas damaged during construction. This increases the cost of shop-coated steel.

How much the cost increases will depend on damage during erection, number of bolt patterns and diaphragms, and condition of facias after construction. It has been this author’s experience that on all new steel jobs all fascia surfaces get damaged during construction and will need to be cleaned and coated.

On a typical job, the cost for this work typically ranges from $2.50 to $3 per square foot. When added to the overall cost, it worked out to be about the same as painting in the field or more. However, more traffic control is needed to fix the damaged coatings, which can extend the job and cause it to be the same amount of time it would have taken to do all the painting in the field minus the primer.

Case Studies on Painting All Three Coats on Two Maryland State Highway Administration Jobs

Case 1

In March 2014, the Maryland State Highway Administration advertised a bid for the replacement of a dual bridge on I-70 over the Conococheague Creek. This contract required, among other things, to replace the existing structural steel for the bridge and called for all new steel to have all three coats of paint applied in the shop with inspection performed at the shop.

Problems arose once the steel was shipped to the site, as all the faying surfaces (splice plates, diaphragm connections, etc.) were coated with all three coats of paint and once the plates were bolted to the faying surfaces, failures started to occur on all the connection faces (Figure 4). Also, the faying surfaces did not meet slip critical requirements.

In addition to these problems, many areas of the steel had issues with damaged coatings throughout the bridge that needed to be touched up. As this bridge was not a road over road, the facias were not repainted due to cost constraints (Figure 5). The specification could have been written in several different ways to alleviate the problem with faying surfaces and reduce the cost to the state, but most importantly, the inspection in the shop did not identify this problem. The initial specification had all three coats of paint on all steel and did not address faying surfaces. This was not questioned by the paint inspector or the fabricating shop.

The additional costs associated with removing the splice plates and connections, cleaning them down to bare metal, applying a zinc primer to make the connections slip critical compliant, then reattaching them, painting intermediate and finish coats, as well as touch up throughout the bridge, added approximately $150,000 to the cost of this project.

Case 2

In June of 2014, another project in Maryland was advertised for the replacement of a dual bridge on I-70 over MD 63. This contract required, among other things, to replace the existing structural steel for the bridge and called for all new steel to have all three coats of paint applied and inspection performed in the shop.

After having problems with the previous job, the state wanted to have all the steel primed only. When the fabricator was contacted, they had already painted the steel. The fabricator being alerted to the previous problem only painted the zinc primer to the faying surfaces and painted the rest of the steel with all three coats.

This job had problems with damaged coatings throughout the bridge. Bolt patterns and diaphragm connections were only primed, and the fascia surfaces needed to be re-coated due to damage during construction. In the end, the cost for this work ranged from $2.50 to $3 per square foot.

When added to the overall cost, it worked out to be about the same as painting in the field. However, more traffic control was needed to fix the damaged coatings and it extended the job by approximately two weeks—the same amount of time it would have taken to do all the field painting.

Conclusions

Owners and specification writers using a three-coat system in the shop thinking it might save money need to re-evaluate the proposed cost savings. As this author has seen, there is little cost savings, and in some cases, more time and money are needed to perform the rework than it would have been to perform the painting in the field instead of the shop. Owners should evaluate specific details of their projects to determine what type of coating application will provide the best quality and cost for their situation.

While applying all three coats of paint in the shop might be a new trend, owners must ensure that specifications and inspection procedures for a coating system will provide the best possible protection for their structures.

Owners must ensure that no matter what method of painting is done, that they provide for some of the following:

- Appearance of the final product

- Repair procedures for damaged coatings

- Faying surfaces

- Good specification

- Good inspection

- Good painting contractor

(1) All costs given in this article are pre-pandemic.