Corrosion of embedded rebar in the marine environment is mainly due to chloride attack. In addition, reinforced concrete members present in the intertidal zone are exposed to alternate wetting and drying cycles because of continuous waves and tides. The expansive corrosion product from embedded rebar causes cracks that accelerate chloride penetration, eventually spalling the concrete, degrading the mechanical properties of rebar and its bond with concrete, and thereby reducing the overall strength and service life of the structure.1

As discussed in a study by Vanama, et al.,2 the use of dense concrete and coatings have been widely adopted in minimizing the chloride penetration of the concrete. Moisture-cure (MC) polyurethane (PUR) coatings possess certain advantages over the conventional two-component epoxy coatings, particularly in the marine environment.2 Please note that additional details on the work described in this article are contained in Reference 2.

To the best of the authors’ knowledge, no information is available in the literature comparing the use of single-component MC PUR concrete coatings and supplementary cementitious materials (SCMs) with the traditional two-component coating systems in improving chloride penetration resistance of the concrete. The present study is extended to investigate the corrosion mitigation and chloride resistivity of coated concrete in comparison with concrete with and without SCM, like fly ash and ground granulated blast furnace slag (GGBFS), through chloride migration and corrosion acceleration tests.

Experimental Investigation

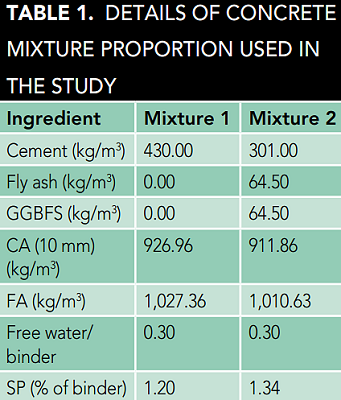

The concrete ingredients used in the study, namely, ordinary Portland cement, coarse aggregate (CA), fine aggregate (FA), water, superplasticizer (SP), fly ash, and GGBFS have been characterized by appropriate test methods and the related properties are described in detail in the Vanama, et al.,2 study. Based on the obtained test results, concrete mixtures were designed with and without mineral admixtures, as given in Table 1, conforming to the specifications set by Indian standards3-4 for the “extreme” exposure condition. Adopted concrete mixtures produced a slump of nearly 55 mm (2.16 in) with a cube compressive strength of 46.82 MPa (6,790.6 psi) for Mixture 1 (without additives) at 28 days; 46.23 MPa (6,705.1 psi) for Mixture 2 (with pozzolans) at 28 days; and 58.83 MPa (8,532.6 psi) for Mixture 2 at 84 days of immerse curing.

The concrete ingredients used in the study, namely, ordinary Portland cement, coarse aggregate (CA), fine aggregate (FA), water, superplasticizer (SP), fly ash, and GGBFS have been characterized by appropriate test methods and the related properties are described in detail in the Vanama, et al.,2 study. Based on the obtained test results, concrete mixtures were designed with and without mineral admixtures, as given in Table 1, conforming to the specifications set by Indian standards3-4 for the “extreme” exposure condition. Adopted concrete mixtures produced a slump of nearly 55 mm (2.16 in) with a cube compressive strength of 46.82 MPa (6,790.6 psi) for Mixture 1 (without additives) at 28 days; 46.23 MPa (6,705.1 psi) for Mixture 2 (with pozzolans) at 28 days; and 58.83 MPa (8,532.6 psi) for Mixture 2 at 84 days of immerse curing.

Further, concrete coatings used in the study are comprehensively characterized to understand their composition, crystalline nature, morphology, wettability, adhesion (with the concrete surface), and water uptake properties. Epoxy coatings used in the study have carbon as a significant component, and the system does not possess a definite morphology. However, MC single-component PUR coatings (MC-M and MC-T) used in this study contain elements that are crystalline with the presence of micaceous iron oxide (MIO) plates <10 nm thick, fused over each other. MC coatings are found to be relatively more hydrophobic than two-component epoxy (EPX) coatings. However, all the coatings are found to be hydrophilic.

To understand the water absorption behavior of hardened coatings by the gravimetric method, water uptake tests were conducted in accordance with ASTM C1794.5 The MC-T coat possesses relatively higher water absorption capacity, followed by MC-M and EPX coatings. Pull-off adhesion tests were carried out in accordance with ASTM D72346 to quantify the strength of the bond between the concrete substrate and coatings. The MC-M system is found to have the greatest adhesive strength with concrete, followed by EPX, whereas in the MCT topcoat, cohesive failure is observed within the coating system.

Rapid chloride migration tests (RCMTs) were conducted in accordance with NT BUILD 4927 on concrete with and without coatings to understand their effect on chloride migration and estimate the diffusion coefficients. Test specimens were cut, preconditioned, coated with EPX and MC coatings, and supplied with the appropriate voltage according to the test standard7 as described in Vanama, et al.2 A multiutility device8 was adopted to monitor the resistance offered by the test specimens during RCMTs.

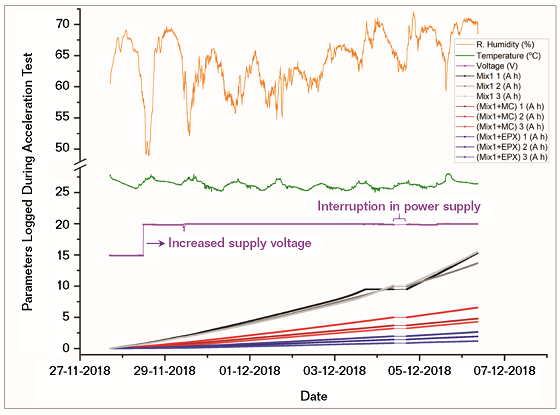

To understand the influence of concrete coatings in mitigating the embedded rebar corrosion, accelerated corrosion tests were performed on pull-out specimens by an impressed current technique using a two-chambered setup.9 A constant voltage of 25.0 V was supplied to specimens until the first crack appeared on the uncoated concrete specimen. Nine total reinforced concrete cubes of 150 mm (5.90 in) in size with a concentric thermomechanically treated (TMT) rebar were cast with concrete Mixture 1. The chemical composition and the mechanical characteristics of the uncorroded TMT rebars used for specimen preparation were as described in Vanama, et al.10 After 28 days of curing, three specimens were coated with EPX (two coats), three with MC-M and MC-T, and the other three without any coat on the concrete surface.

During acceleration, corrosion-associated parameters were monitored by a data logger8 and half-cell potential measurements at regular intervals. At the end of corrosion acceleration, the rebars were retrieved from the pull-out specimen for gravimetric analysis. Rebars were cleaned in accordance with ASTM-G111 and weighed. The actual mass loss of rebar was estimated by comparing with their pristine condition.

Results and Discussion

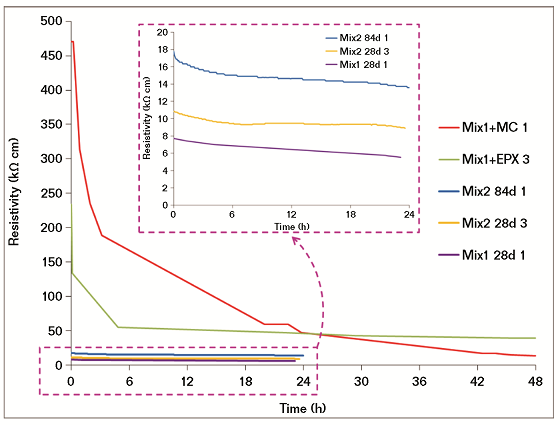

The electrical resistivity offered by a specimen against the chloride migration was estimated from the data logged during RCMTs, and the typical pattern is given in Figure 1. At the start of the test, MC-coated specimens offered nearly 102 times greater resistance compared to control specimens (Mixture 1 at 28 days) and continued to offer the highest resistivity than any other system used in the study for the first 24 h of the migration tests. Scanning electron microscopy indicated that MC coatings are reinforced with MIO plates, which cause a labyrinth effect12-13 that makes the migration path of corrosive media in the coating more tortuous, thereby increasing the time when corrosive media reach the metal substrate. However, resistance offered by MC coatings decreased over the next 24 h, unlike EPX coatings, which might be because the MC coatings used in this study are hydrophilic and possess high water absorption coefficients compared to the EPX coatings.

For the MC coating systems, the water uptake coefficient was higher for MC-T than MC-M, which can be the reason behind the sudden decrease in the resistivity offered by MC coatings against chloride migration in the first 3 h of the migration test. The adhesion test indicated that MC-T coatings had the least adhesive strength within the coating systems, which might be the reason for the sudden decrease in resistance offered by the MC specimen against chloride ion penetration. The EPX had the least water absorption coefficients among the tested coatings systems and offered higher resistance to chloride penetration throughout the migration test period. Both EPX and MC coating systems were more effective in terms of resistance to chloride-ion penetration than the concrete with SCMs (Mixture 2) cured for 28 and 84 days as well.

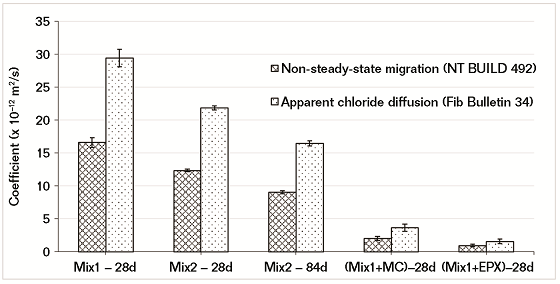

Based on the chloride migration depth and the environmental conditions maintained during the test, the apparent chloride diffusion coefficient (Dapp) and non-steady-state migration coefficient (Dnssm) are estimated in accordance with the Fib Bulletin 3414 and NT BUILD 492,7 respectively, and presented in Figure 2. Concrete with coatings performed better compared to uncoated concrete with additives, even at 84 days of curing. MC and EPX-coated concrete specimens offered nearly 4.55 and 9.51 times better resistance, respectively, to chloride migration when compared to 84 days cured concrete specimens with SCMs.

During the corrosion acceleration test period, associated corrosion parameters were recorded at a 5-min interval using a data logger8 and they are presented in Figure 3. For the supplied voltage, cumulative current flow readings are observed to be higher for concrete specimens coated with MC compared to that of the EPX system. Thereby, the overall chloride penetration

resistance offered by MC-coated concrete specimens was less than that of the EPX-coated specimen. Dense concrete cover of nearly 67 mm (2.64 in) and the concrete surface coated with EPX and MC coatings made the specimens highly resistive to ion migration. It demonstrated the limitations of the half-cell measurements for monitoring the corrosion of rebar embedded in EPX or MC-coated concrete, where the RCMT is used for accelerating the rebar corrosion.

The actual mass loss of rebar was estimated by comparing with their pristine condition, which is estimated to be 3.793% ±0.266% for “Mix1” concrete specimens, 0.499% ±0.096% for “Mix1+MC” specimens, and 0.165% ±0.162% for “Mix1+EPX” specimens. It is implicit that both concrete surface coatings are highly effective in mitigating the corrosion of embedded rebar and MC coatings reduced the mass loss due to corrosion by 7.6 times compared to uncoated specimens, whereas EPX coatings reduced the mass loss by 23 times.

Major conclusions from the study are as follows:

- At the start of the rapid chloride migration test, MC-coated specimens offered nearly 102 times greater resistance to chloride migration compared to the concrete without mineral admixtures. This might be because MC coatings used in the study are reinforced with MIO, which makes the migration path of corrosive media in the coating more tortuous.

- Even though concrete with and without additives have shown nearly the same strength at 28 days, concrete with additives has a 25.6% lower non-steady-state migration coefficient than concrete without any pozzolanic material. The value reaches 45.5% after 84 days of curing.

- The non-steady-state migration coefficients of the concrete cured for 28 days and coated with MC and EPX coatings were nearly 22% and 11% of that of concrete with SCM cured for 84 days, respectively.

- The performance of the selected coating products with respect to chloride ion penetration resistance observed during the rapid migration tests can be expressed in the following order from best to worst ranking: {(Concrete without SCM) 28d + EPX} > {(Concrete without SCM) 28d + MC} > (Concrete with SCM)84d > (Concrete with SCM) 28d > (Concrete without SCM)28d.

- The present study demonstrates the limitations of the half-cell measurements for monitoring the corrosion of rebar embedded in coated concrete, where an impressed current method is used for accelerating the corrosion of rebar.

- MC coatings reduced the mass loss due to corrosion of embedded rebar by 7.6 times compared to uncoated specimens, whereas EPX coatings reduced the mass loss by 23 times. Without any exposure of EPX coatings to UV radiation and temperature changes, the system offered better resistance to chloride penetration.

Both MC and EPX coatings are found to be highly effective in terms of electric resistivity offered against chloride migration and mitigating the corrosion of embedded rebar. However, in terms of mixing, recoat time, and time required for curing, single-component MC PUR coatings are more use ful in the marine environment compared to epoxy coatings.

NOTE: Readers who wish more detail can download that manuscript from the AMPP web site (www.nace.org) and refer to the Vanama, et al.,2 study.

Acknowledgments

The authors acknowledge the Department of Civil Engineering and Industrial Research and Consultancy Centre—IIT Bombay for financially supporting the research work. The authors would like to thank Harinee Addepalli for assisting in characterizing the coatings.

References and About the Authors