The U.S. Southwest Research Institute (SwRI) (San Antonio, Texas, USA) was recently awarded1 a $1.3-million project from Washington River Protection Solutions (WRPS) (Richland, Washington, USA), a contractor to the U.S. Department of Energy (DoE).

The contract calls for SwRI to build a robotic inspection system designed specifically to inspect the bottoms of massive underground double-shell tanks located at the decommissioned Hanford nuclear production complex on the Columbia River in eastern Washington.

Built in 1943, the Hanford complex was once home to the world’s first full-scale plutonium reactor.2 The last reactor closed in 1987, and in 1989, DoE began large-scale cleanup efforts. Both single-shell and double-shell tanks are used on the site to store 56 million gallons of chemical and radioactive waste.

Ultrasonic Inspection of Tank Liners

A key process in the tank operations mission is to remove radioactive and chemical waste from 132 of 149 single-shell tanks that still hold waste and transfer the waste to double-shell tanks. The double-shell tanks are essential for continued safe storage until the waste can be treated for disposal.

At 1.0 million gal (3.8 million L) of capacity, each double-shell tank holds waste in a primary vessel that is encased in a secondary vessel to further protect the surrounding environment and needs to be inspected regularly.

“The biggest challenge for inspection is the bottom of these vessels,” says Adam Cobb, project lead and a principal engineer in SwRI’s mechanical engineering division. “While WRPS has performed visual and ultrasonic inspection of the bottom of the primary tanks, this tool is unique in that it can perform ultrasonic inspection of both primary and secondary liners.”

Detection of Cracks, Corrosion

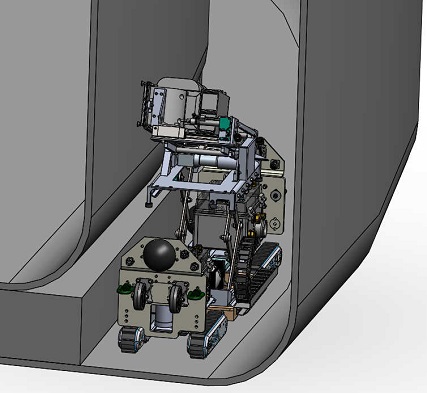

For this reason, WRPS tapped SwRI to create a robotic ultrasonic inspection system that can identify flaws in the carbon steel tanks while operating in the 30-inch (76.2 cm) wide space between the primary and secondary vessels. The design phase was completed in 2019.

For this reason, WRPS tapped SwRI to create a robotic ultrasonic inspection system that can identify flaws in the carbon steel tanks while operating in the 30-inch (76.2 cm) wide space between the primary and secondary vessels. The design phase was completed in 2019.

“Our robotic inspection system uses SwRI-developed guided wave inspection technology to nondestructively find defects or thinning in the metal so mitigation steps can be taken,” Cobb said. “Guided wave technology operates at very low frequencies. The sound waves travel down the primary wall into the vessel bottom; the inspection system listens for the sound waves to reflect from any damage like cracks or corrosion.”

An inspection of one of the Hanford site’s tanks in 2017, after most of the waste had been removed from the tank, had found widespread pitting at the base of its inner shell.3 Inspections of other tanks are ongoing.

Delivery Planned by End of 2020

The robot housing the system will be several feet long but narrow, allowing it to be lowered into the space between the primary and secondary tanks and then expand to perform the inspection.

Cobb and his mechanical engineering colleagues are leading the project, creating the sensors and the inspection system while collaborating with robotics experts in SwRI’s intelligent systems division to develop the robot.

Construction of the robotic system will begin later this summer, with delivery of the system planned for the end of calendar year 2020.

References

1 “SwRI Receives $1.3 Million to Build Robotic Inspection System for Nuclear Waste Storage Tanks,” SwRI Press Releases, June 23, 2020, https://www.swri.org/press-release/robotic-inspection-system-chemical-radioactive-waste-wrps (July 20, 2020).

2 “Hanford Site,” Wikipedia, the free encyclopedia, https://en.wikipedia.org/wiki/Hanford_Site (July 20, 2020).

3 “Tank Integrity Studied at Radioactive U.S. Waste Storage Site,” Materials Performance Articles, Nov. 1, 2018, http://www.materialsperformance.com/articles/material-selection-design/2018/11/tank-integrity-studied-at-radioactive-us-waste-storage-site (July 20, 2020).