A new project,1 funded in part by grants from the European Commission’s (Brussels, Belgium) Horizon 2020 research and innovation program and the Research Council of Norway (Oslo, Norway), has developed an ultrasonic, three-dimensional (3-D) rolling scanner for the nondestructive testing (NDT) of concrete structures.

Named COBRI and developed by Norwegian startup company Elop AS (Hamar, Norway), the multi-element handheld scanner is designed to quickly inspect and assess large surface areas through its polymer-based ultrasonic transducer design, which yields high-resolution images for real-time interpretation by showing the concrete’s internal state. The transducer device converts variations in physical characteristics, such as pressure or brightness, into an electrical signal.

The 3-D scanner uses separate transmitter and receiver arrays sealed inside liquid-filled cylinders, with each cylinder coupled to the concrete through elastomer rings. The tomograph—an imaging device utilizing penetrating waves—can send and receive signals at any time, as coupling between the transducer and concrete is always maintained.

Potential Concrete Applications

Infrastructure such as bridges, railways, and roads are usually made of reinforced concrete, which needs continuous monitoring to ensure structural integrity and safety. However, these large concrete structures have long posed challenges for traditional inspection methods, the company explains, due to the wide range of aggregates—particulate material such as sand, gravel, slag, and crushed stone—in the material. The handheld roller allows for a more intense focus on each individual area.

“The early, proactive detection of corrosion, cracks, and delaminations could lead to savings of billions [of dollars] worldwide,” says Philippe Olivier, CEO of the startup development company. “This innovative solution will simplify and improve current bridge inspection methods,” he adds, noting that potential users include constructors, inspection consultants, and NDT service providers.

For larger horizontal areas, a trolley version of the product using the same basic rollers is currently being designed. Because the terrain for inspections is not always flat and some structures require costly scaffolding to access, Olivier’s company sees connecting the rolling scanner to robots or crawlers as a potential solution.

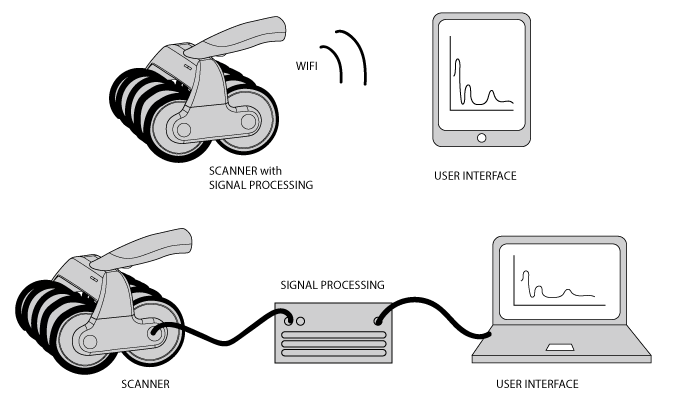

The scanner also requires less specialist training to use, Olivier explains, with field data transferred to a central site for analysis by experts. Successful field tests of the device were conducted in collaboration with industry partners and bridge inspection specialists.

PVDF Materials

The scanner uses broadband transducers with a low frequency of between 50 and 250 kHz and is comprised of a polyvinylidene fluoride (PVDF) material with piezoelectric properties.

While PVDF materials are generally known to yield both higher loss and lower coupling in transducers relative to conventional piezoelectric ceramics, Olivier’s team came up with an innovative idea. To improve each transducer’s efficiency, sensitivity, and bandwidth, the team equipped each transducer with eight multilayer elements, made by stacking the PVDF films in folded sequences using adhesives.

Because the input impedance of PVDF is high, using multiple layers generates the necessary amount of acoustic power. The layers are connected acoustically in series and electrically in parallel.

“The main technological breakthrough is a new design for capturing real-time ultrasound data from concrete structures and presenting data in a human, readable, 3-D video format,” Olivier explains.

How It Works

The use of separate transmitter and receiver rollers eliminates the possibility of interference, Olivier says, as the reflection from transmitted pulses against the polymer, elastomer, and concrete surface does not interfere with the receiving signals on the other roller.

Images are reconstructed using a synthetic aperture focusing technique (SAFT) algorithm. This SAFT process aims to improve the signal-to-noise ratio and the resolution of the image, which is shown on an integrated display monitor. The developers say this provides superior 3-D results when compared to traditional testing methods.

Because of the broadband transducer, the operating frequency of the device can be adjusted for customized penetration depth and resolution. In all, each in situ inspection takes place very quickly, with times ranging from 100 to 1,000 mm/s, depending on the resolution. The penetration depth ranges from 150 to 500 mm, with 3-D, real-time video obtained at a resolution of ~10 mm.

This resolution can detect rebar and the separation of materials into layers, as well as cracks and other defects.

Potential Use on Other Materials

The concrete scanner has been in development since 2013, and the company plans to launch the COBRI product into the market for commercial use later this year. In parallel to this, Olivier says, they are currently building up their sales force and production capacity.

Based on the versatility of the patented design, developers believe the concept can also be expanded to the NDT of other solid materials and applications besides concrete. To that end, developers began creating a spinoff scanner in January 2018. By raising the resonance frequency of the roller with a different multilayer transducer design, the company says this instrument can be used to inspect composite materials, thick and thin metals, and welded joints.

“The impact doesn’t end with detecting problems in reinforced concrete structures,” Olivier says of the innovation. He notes that potential NDT structures for the spinoff project could include windmill blades, welding inspection, tanks, and ship hulls.

Source: Elop AS, www.elop.no. Contact CEO Philippe Olivier—email: philippe.olivier@elop.no.

Reference

1 “Ultrasound Scans for Damage to Concrete Bridges,” CORDIS Projects & Results, May 11, 2018, https://cordis.europa.eu/result/rcn/227700_en.html (June 13, 2018).