In the United States, two storage methods are acceptable for spent nuclear fuel after it is removed from the reactor core. Specially designed spent fuel pools at individual reactor sites around the country are one storage method. Spent nuclear fuel that has been cooled in a spent fuel pool for at least a year can also be stored in a sealed dry storage system (DSS). These systems are located at operating and decommissioned nuclear reactor sites throughout the United States. The DSS is typically a steel cylinder that is either welded or bolted closed. The steel cylinder provides leak-tight confinement of the spent fuel. Each cylinder is surrounded by additional steel, concrete, or other material to provide radiation shielding.1

A DSS is often stored in locations where exposure to moisture and airborne salts is probable. To evaluate the possibility of a DSS being affected by microbiologically influenced corrosion (MIC) during extended storage in humid air, researchers with the Southwest Research Institute (SwRI) (San Antonio, Texas, USA) used a combination of carbon steel (CS) and stainless steel (SS) probes and coupons in simulated humid environments to test for corrosion indicative of MIC.

NACE International member Xihua He, principal corrosion scientist, and Amy De Los Santos, research scientist, both with SwRI, note that CS, low-alloy steel, and SS are materials used to fabricate a DSS, which is commonly exposed during storage to outdoor environments where airborne salts, along with rain, fog, snow, dew condensation, and capillary condensation can generate salt-laden moisture layers on the steel surfaces. A DSS can also be stored in sheltered atmospheric environments where airborne salts and other airborne particulates can access the space through air vents and deposit on steel surfaces. Depending on the location of the storage facilities, these salts can originate from chloride-laden marine environments, road deicing salts, and condensed water from the power plant’s cooling towers, as well as a range of nearby industrial, agricultural, and commercial activities. They comment that when temperatures fall well below 230 °F (100 °C) during storage and the dewpoint is reached (the temperature where some of the water vapor in the air condenses to a liquid), the deposited salts absorb moisture from the air and dissolve in it, which can create an aqueous solution.

He and De Los Santos conducted experiments that would evaluate the presence of MIC under high and low relative humidity (RH) conditions. They explain that MIC is a process where numerous types of microbes, ranging from iron-oxidizing, iron-reducing, sulfate-reducing, acid-producing, and exopolymer-producing bacteria, cause metals to deteriorate due to their metabolic activities. Biofilm formation is the precursor to MIC, and most of the available data on MIC focus on metallic components with continuously wet surfaces. Information on MIC in atmospheric conditions where metal surfaces could experience dry and wet cycles due to daily and seasonal humidity and temperature variations is limited. Their objectives for this study were to develop methods for evaluating MIC of CS and SS in humid air, and to investigate whether DSS surfaces could be affected by MIC during extended storage.

For the study, an environmental chamber was used to expose CS and SS coupons, as well as multielectrode array sensors, to an atmosphere with controlled temperature and RH. All tests were conducted at 122 °F (50 °C) within a RH range where deliquescence could occur. The metal surface temperature and air temperature were the same during the tests. The dry and wet conditions were achieved by setting the RH to 35% and 90%. The combination of 50 °C and 90% RH accelerated the formation of wet conditions for comparison. Test media—clean sand, field sand, simulated sea salt, soil, soil inoculated with bacteria, and a mixture of simulated sea salt with soil inoculated with bacteria—were placed on top of the metal coupons. According to He and De Los Santos, the sand and soil simulated particulate matter from the atmosphere that could settle onto the DSS canisters. Simulated sea salt, a mixture of mostly sodium chloride (NaCl) with other salts, was used to simulate conditions near bodies of saltwater.

The soil, a commercial potting mix with a pH of 5.6, had a measured chloride content of 68 ppm. The clean sand was washed and the field sand was collected from an outdoor environment that had been exposed to contaminants for years. Bacillus licheniformis (BL) bacteria were used to inoculate some of the test media. BL produce acid from several sugars, and are also corrosive nitrate reducers. The growth temperatures for these bacteria are 86 to 131 °F (30 to 55 °C). They do not require salt for growth, but can tolerate a NaCl concentration of 2 to 7%. The colony forming unit (CFU) counts for the soil and soil inoculated with BL were 3.95 x 106 and 1.8 x 106, respectively. No bacteria were found in the clean sand or field sand.

CS and SS samples topped with clean sand, sea salt, soil, and soil inoculated with BL were exposed to a RH of 35% for two and a half months, while CS and SS samples topped with inoculated soil mixed with sea salt were exposed for only one month to a RH of 35%. For the tests at 90% RH, samples topped with field sand were added to the test. The samples topped with clean and field sand, soil, and BL-inoculated soil were exposed for three months at 90% RH; the samples with simulated sea salt were exposed for two and a half months; and the samples topped with BL-inoculated soil mixed with sea salt were exposed for one month.

The bacterial strains in the media during and after testing were analyzed to obtain CFU counts and compared to the original counts before tests. The post-test samples were examined under a microscope for corrosion morphology. Overall, the post-test bacteria count in the 90% RH test was higher than in the 35% RH test, which He and De Los Santos attribute to the higher RH. Additionally, the sea salt deliquesced fully at 90% RH and formed a solution.

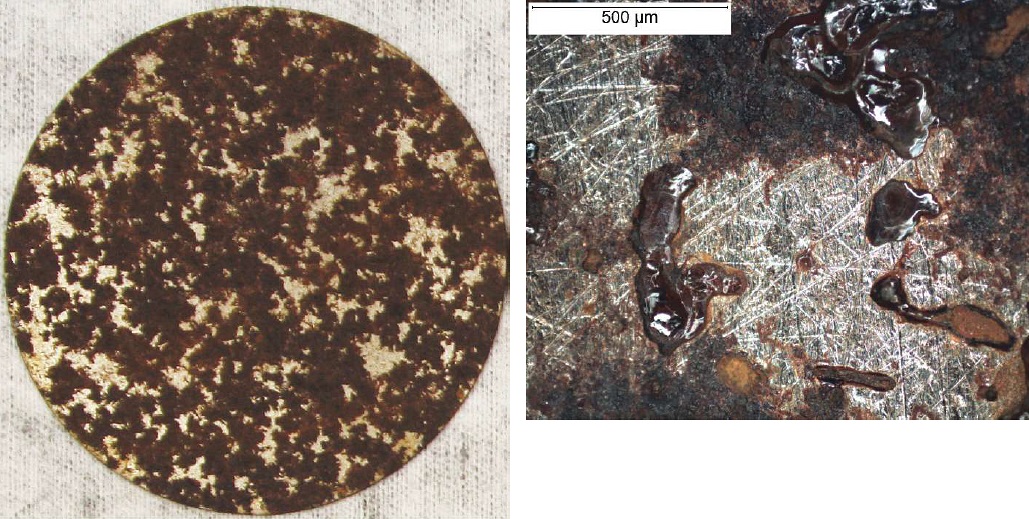

After exposure, extensive corrosion was observed on all CS samples exposed at 35% RH except for the one topped with clean sand. Corrosion was observed on the SS sample topped with simulated sea salt, and pitting was observed on the SS sample with soil inoculated with BL, which could be associated with bacterial activity. In the soil mixed with sea salt and inoculated with BL, the number of bacteria increased one order of magnitude during the test, which indicated sea salt may have stimulated the growth of bacteria, even at 35% RH.

Extensive corrosion was found on all CS samples exposed with all test media at 90% RH. An elongated corrosion feature on the CS surface topped with BL-inoculated soil could be associated with bacterial activity. This also was consistent with the post-test CFU counts. In the test of BL-inoculated soil mixed with sea salt, the CS specimen showed patches of localized corrosion after one month. The soil medium on top of the coupon was strongly attached and difficult to remove. It is very likely that the biofilm from bacteria activity was strongly adhered to the coupon and formed a localized concentration cell. SS pitting was observed with simulated sea salt and other media. Pitting was the most severe on the sample with BL-inoculated soil mixed with sea salt, although the test time was the shortest. He and De Los Santos note that the pits could be credited to the synergism between bacterial activity and sea salt.

Test results in this study showed that the number of bacteria detected at both 35% and 90% RH in soil-containing media was on the order of 106 and 107, which is a significant amount. This provides evidence that some microbes can survive under the low water conditions. Although microbes favor consistent conditions, including temperature, He and De Los Santos comment that most of them can tolerate seasonal changes.

“During wetting if nutrients are also available, microbes would grow, forming a patchy biofilm on the metal surface. During dehydration, the polymer matrix produced by the attached bacteria would remain on the surface in an inactive state until rewetting. Refreshing during rewetting would introduce water and nutrients that revive the bacteria, leading to re-initiation of localized attack on the surface.”

Because of the evidence of potential MIC in this study’s results, He and De Los Santos conclude that microbes could exist in deliquescent solutions under atmospheric environments and potentially cause corrosion at elevated temperatures. The initiation and extent of MIC, however, will depend on the actual environmental conditions—particularly temperature, RH, radiation, nutrients, and the chemistry and quantity of deposits on the steel. Since these tests were conducted under accelerated conditions particularly favorable to MIC, testing also should be done under actual atmospheric conditions to evaluate the potential for MIC.

More information on the study, funded by SwRI, can be found in CORROSION 2017 paper no. 9709 by Xihua He and Amy De Los Santos, that was presented in New Orleans, Louisiana, USA.

Contact Xihua He, Southwest Research Institute—email: xhe@swri.org.

Reference

1 “Dry Cask Storage,” United States Nuclear Regulatory Commission, https://www.nrc.gov/waste/spent-fuel-storage/dry-cask-storage.html (November 3, 2017).