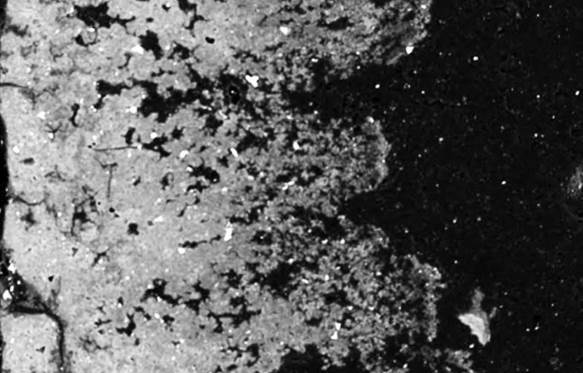

A recent study1 of lead service lines in the damaged drinking water system in Flint, Michigan, revealed a “Swiss cheese” pattern in the pipes’ interior crust, with holes where lead used to be.

The study—led by researchers at the University of Michigan (Ann Arbor, Michigan)—supports the understanding that lead leached into the system during the Flint water crisis2 in 2014 and 2015 because that water was not treated to prevent corrosion. While previous studies had pointed to this mechanism, they say this is the first direct evidence.3

The research team believes the findings underscore how important uninterrupted anticorrosion treatment is for aging water systems.

Lead Service Line Samples

The Michigan team focused on a layer of metal scale—essentially lead rust—inside 10 lead service line (LSL) samples from around Flint. Using a scanning electron microscope, they studied the texture of the rust layer, as well as its chemical composition. From there, they used their analysis to estimate that the average LSL sample released 18 g of lead during the 17 months that Flint water flowed through the system without corrosion controls.

“This is the amount of lead that would have entered a single home,” says Terese Olson, a Michigan associate professor of civil and environmental engineering and lead author of the study. “If we average that release over the entire period the city received Flint River water, it would suggest that on average, the lead concentration would be at least twice the EPA action level of 15 parts per billion [ppb].”

The lead ended up in several places, according to the researchers.

“Some was consumed,” Olson says. “Some washed down the drain. Some might still be stored in the homes’ plumbing. In other words, there is a chance that some of that lead is a potential health risk even after the lead service line is removed.”

If a lead line connects to a home with galvanized steel pipes, for example, those pipes can act as lead sponges that can hold and then later release particles containing the toxic metal, according to Brian Ellis, a Michigan professor and co-author of the study.

Examining Pipe Linings

In addition to examining the samples, researchers also pulverized the pipe linings to analyze what they were made of. In the Flint pipes, they found a greater ratio of aluminum and magnesium to lead than is typical for lead service lines, when compared with data from 26 other water utilities.

Using correlative associations of lead with aluminum and magnesium in Flint scale samples, and average LSL abundances of aluminum and magnesium from the literature, the team estimated that at least 2.7 ± 1.5 g/m of lead were released from the pipe scale.

“We estimated how much lead was ‘missing’ in order to bring the Flint lead scale into line with the amount of aluminum and magnesium that was reported in other communities,” Olson says. “That missing lead represents what was leached from the pipes during the Flint corrosion episode.”

As lead pipes age, the atoms on their surface react with oxygen and other chemicals in the system and become oxidized, or rusted. While acknowledging that adequate water treatment does not prevent that process, the researchers say it does prevent the breakdown of the rust layer.

“It’s like when you put an old penny in a glass of Coke and watch it get shiny again,” Ellis says. “The acid in the Coke dissolves the copper corrosion product. This is similar to what happened in Flint’s lines. You can have a stable corrosion product, but when you change the water chemistry the oxidized lead compounds on the surface may become unstable and readily dissolve.”

Water utilities with both corrosive water and lead service lines in their systems add compounds called orthophosphates to prevent that breakdown. When Flint switched from Lake Huron water to the more corrosive Flint River to save money, researchers say the utility failed to adjust its treatment process by adding orthophosphates.

“Beyond implications for Flint, we demonstrated that small changes in water chemistry can release what was stable lead in a fairly quick pulse,” Ellis says. “This is a known condition. So while we weren't surprised, being able to show it underscores the importance of maintaining uninterrupted lead corrosion control.”

Further Research Ahead

Going forward, the researchers say they hope to verify their prediction of the amount of lead released by analyzing a lead service line from a vacant home that was not exposed to the corrosive Flint water. To do this, they must find a home that has had its water turned off since 2014 and has a LSL that can be dug up.

Led by Olson and Ellis, the research team includes six undergraduate students, four graduate students, two post-doctoral students and six faculty members from Michigan’s campuses in Ann Arbor and Flint. The work was jointly funded by the school and the Dow Sustainability Fellows program of Dow Chemical (Midland, Michigan).

Source: University of Michigan, www.umich.edu. Contact Terese Olson, University of Michigan—email: tmolson@umich.edu; and Brian Ellis, University of Michigan—email: brellis@umich.edu.

References

1 T.M. Olson, et al., “Forensic Estimates of Lead Release from Lead Service Lines during the Water Crisis in Flint, Michigan,” Environ. Sci. Technol. Lett., July 19, 2017, http://pubs.acs.org/doi/pdf/10.1021/acs.estlett.7b00226 (Sept. 11, 2017).

2 K. Riggs Larsen, “The Science Behind It: Corrosion Caused Lead-Tainted Water in Flint, Michigan.” MP, June 7, 2016, http://www.materialsperformance.com/articles/material-selection-design/2016/06/the-science-behind-it-corrosion-caused-lead-tainted-water-in-flint-michigan. (Sept. 11, 2017).

3 N.C. Moore, “Missing lead in Flint water pipes confirms cause of crisis,” University of Michigan News, July 28, 2017, http://ns.umich.edu/new/releases/24983-missing-lead-in-flint-water-pipes-confirms-cause-of-crisis (Sept. 11, 2017).