Researchers at the University of Texas at Arlington (Arlington, Texas) (UTA) are partnering on multiple projects with local city government agencies to inspect concrete manhole shafts and sewer pipes for corrosion and develop a methodology to prioritize which areas should be treated first.

With more than $1 million in combined investment, the city believes the results from these collaborative inspection studies can lead to more efficient spending and serve as a template for other cities around the country to better protect infrastructure in the years ahead.

“The new study will give Arlington water engineers and other cities across the country the data they need to protect vital infrastructure and spend funds wisely,” says Buzz Pishkur, water utilities director for the city. “UTA is a renowned center for the study of pipe technology and evaluation of alternate pipeline materials to meet the needs of cities. We are fortunate to have a center of research in our city, and [we] value the partnership on this and other key infrastructure efforts.”

Concrete Manhole Initiative

The latest initiative between the school’s civil engineering department and city involves the inspection of 350 concrete manholes for corrosion. The Arlington City Council approved the three-year, $474,723 project earlier this year.

The corrosion of these manhole shafts can threaten the structural integrity of sanitary sewer mains and allow rain and other runoff from the surface to enter the wastewater system, Pishkur explains.

Each manhole to be inspected ranges from 4 to 5 ft (1.2 to 1.5 m) in diameter and from 4 to 45 ft (1.2 to 13.7 m) in height, according to UTA researchers, who note that the project will inspect manholes of different categories, types, and geographic locations.

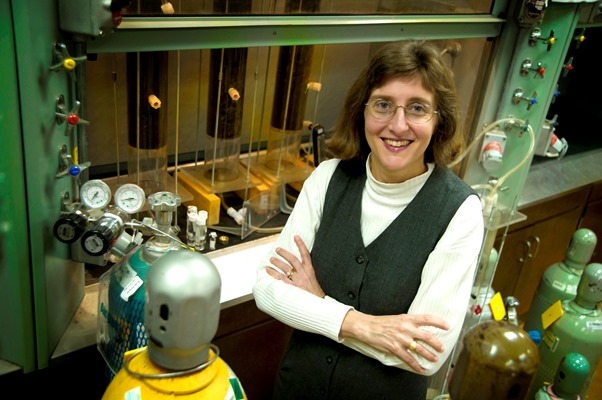

Led by engineering professors Melanie Sattler, Victoria Chen, and Arpita Bhatt, their team plans to measure corrosion influencers such as hydrogen sulfide (H2S) gas, which can be converted to sulfuric acid (H2SO4) by microbes in the sewer. The H2SO4 can also corrode pipes adjacent to the manholes.

The UTA project involves the use of sensors to measure the amount of H2S gas, study the velocity of flow, and inspect corrosion that might already be underway to determine which manholes need corrosion protection solutions first.

UTA students will be expected to go into the field and physically implement the sensor programs to collect the data, the professors explain.

The study involves just 350 manholes, which represent only a small portion of the ~19,000 across the city. However, the goal is to use the data from the 350 inspected manholes to develop a system allowing Arlington to better prioritize the remainder of its manholes and decide which need treatment first.

“It makes sense for Arlington to develop a system for prioritizing protection of its manholes,” Sattler says. “Manholes can corrode because of the creation of hydrogen sulfide gas. Some readings can be really, really high. We will determine which manholes need a protective coating to protect them from corrosion. To coat all of them would not be feasible.”

From there, the city plans to conduct a cost-benefit analysis of available corrosion protection options, with possible solutions including pipe slopes to reduce the generation and release of H2S.

According to UTA officials, the manhole contract was an offspring from an earlier sanitary sewer assessment project granted by the city to UTA in late 2015.

Sewer Pipe Evaluation Project

Under a separate $882,000 contract, another group of researchers led by UTA’s civil engineering department is utilizing a robotic system to study all city sewer pipes with a circumference of 60 in (1,524 mm) or greater. In all, the project will evaluate nearly 48 mi (77.2 km) of pipes over three years.

“The technology is available today that could give us a good picture of what’s going on in those pipes,” Pishkur says. “This refined understanding will then allow us to optimize the operation and dependability of our sewer system.”

Utilizing a MSI HD (multi-sensor inspection, high-definition) Profiler floating robot on wheels, the team gathers information from inside pipes by using cameras, lasers, and sonar. The lasers and video cameras are used to measure and record images of internal defects that can cause cracks, delamination, and other failures. Meanwhile, the sonar profiling system beneath the robot analyzes pipe walls and other conditions underneath the water line, such as a buildup of debris or sediment.

The 50-lb (22.7-kg) robot—built by Red Zone Robotics (Pittsburgh, Pennsylvania), with an investment of nearly $500,000—is lowered into the sewer through a manhole and pulled through each pipe by a cable. Engineers review the video footage and laser and sonar reports via laptop.

Like the manhole project, the robotic system is designed to pinpoint trouble spots and prioritize which should be mended or replaced first. When a weakness is discovered, officials with both the school and city dig down to extract a segment of the pipe. Researchers then analyze the pipe sample in a laboratory to determine its current condition and remaining life.

More Efficient Infrastructure Spending

“The evaluation allows us to make more informed decisions about infrastructure replacement. That could lead to fewer rate hikes and better use of our capital money,” Pishkur says. “We can pinpoint where to spend the money at a lower cost to residents and with the least amount of inconvenience. Planning for pipe replacement is better than doing it when disaster hits and there’s significant damage to streets, lawns, and structures.”

The sewer pipe project is led by Ali Abolmaali, chair of UTA’s civil engineering department and director of UTA’s Center for Structural Engineering Research and Simulation. Other team members include Yeonho Park, a UTA civil engineering post-doctoral fellow, and Mohamad Razavi and Mohsen Shahandashti, senior lecturers in civil engineering.

“We’ll make recommendations for what to do based on where the robots and sonar detects anomalies within the pipes,” Abolmaali explains. “This research could provide a blueprint for other cities to copy.”

In the second phase of the project, which has yet to begin, Abolmaali’s team will recommend a new system of fiber-reinforced pipes to use in the future—which are more sustainable and resilient, he says.

The sewer pipe project is scheduled to conclude in 2018, while the concrete manhole project is expected to continue until 2020.

Sources: UTA, uta.edu; City of Arlington, arlington-tx.gov.