Post-tensioning (PT) has evolved to become a prime methodology for bridge construction, both in the United States and throughout the developed world. Advantages include reduced materials of construction, a more streamlined appearance, and in the case of the balanced cantilever construction method, the ability to span irregular terrain and high-volume roadways and waterways without traffic disruption. The technology typically employs strands comprised of seven, spirally wound, high-strength steel wires that conform to ASTM A4161 with a guaranteed ultimate tensile strength (GUTS) of 1,860 MPa (270 ksi).

Most commonly, 12, 15, or 19 strands comprise a tendon, with these being contoured along the bridge span length such that, upon stressing, concrete that would otherwise be in tension and subject to cracking is instead in compression. Tendons can be either bonded or unbonded, where for the former, the strain in strands and concrete is the same at the limit state, whereas for the latter it is not. Also, tendons can be either internal, in which case they are cast into the span concrete, or external, where they are not so encased, except at anchorages and deviation blocks. Subsequent to stressing, the duct in which the strands are placed and stressed is filled with grout.1

However, despite the protection afforded by the duct and grout, corrosioncaused tendon failures have been reported as early as two years post construction.2-3 The initial tendon failure in the United States was disclosed on the Niles Channel Bridge in the Florida Keys in 1999 and was attributed to corrosion from either bleed water or to water from an external source within a grout void.4 Such failures have been designated as Case 2 and typically occur several decades post construction.

Examples of corrosion-caused tendon failures in Florida, in addition to the Niles Channel failure, include multiple occurrences on the Mid Bay Bridge5 near Destin, Florida; the Sunshine Skyway Bridge over Tampa Bay; the Ringling Causeway near Sarasota; and the Roosevelt Bridge over the Saint Lucie River near Stuart. Subsequent to the Niles Channel Bridge failure, the industry transitioned to thixotropic grout; that is, grout that becomes less viscous under pressure and can thereby better fill tortuous void spaces.

However, despite this, tendon failures have continued, typically within a single decade of construction, due to what has been termed “soft grout;” that is, grout that is chalky, unhardened, separated, and segregated, with free water and elevated sulfate concentrations (termed Case 1).6-7 Figure 1 shows a cross-section view with various phases identified for one of two tendons that failed on the Ringling Causeway Bridge some seven-plus years after construction.

The material labeled “wet plastic grout” is soft grout. Upon opening this tendon, free water flowed from the void area. Fifteen other tendons with corrosion in the same general vicinity as the two failed ones were also replaced. Such issues can only be expected to increase with time as PT bridge structures age. As an indicator of this, in 2006 the U.S. National Bridge Inventory rating for 273 segmental PT bridges was 7.1 (good); however, only 12 years later, tendon corrosion issues were reported on eight major such bridges.

Bridge Tendon Failure Modeling

In response to the PT bridge integrity issues previously described, the Federal Highway Administration sponsored studies for the purpose of better assuring tendon integrity.8-11 The resultant modeling considered that, first, wire fracture occurs at the site of maximum cross section loss once the GUTS is reached and, second, corrosion loss at such sites is normally distributed across the wire population, as has been shown to be the case.6,12

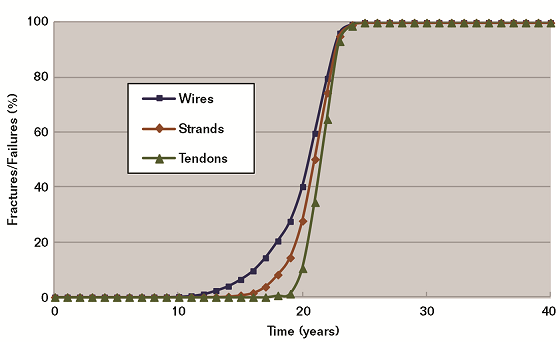

Figure 2 provides an example of the resultant projection for wire and strand fractures and tendon failures as a function of time for the specific case where mean corrosion rate (µ[CR]) is 0.08 mmpy (3.0 mpy) and standard deviation (s[CR]) is 50% of the mean. Here, Tf (time of an initial fracture/failure for wires, strands, and tendons) is 11.5, 15.6, and 18.6 years, respectively.

Subsequently, each trend is sigmoidal and progressively increases with time initially, passes through an inflection point, and subsequently moderates. Figure 3 then plots Tf for wires, strands, and tendons as a function of µ(CR). The finding that a bridge tendon failure in Europe was reported at an age of two years and for the Ringling Causeway Bridge 7.5 years, as previously noted, indicates that mean corrosion rates in excess of 10 mmpy can occur. This is undoubtedly the case since wire and strand fractures necessarily predate actual tendon failures.

The previous analyses were predicated upon a system with 162 tendons, which for a typical bridge of span-by-span construction with three tendons on each side, equates to 27 spans total. Losing two tendons on a given span reduces structural capacity by ~33%; however, if these two tendons are on the same side of the span, excessive deflection and concrete cracking would occur and the bridge would be closed for immediate repairs.

In the case of the Ringling Causeway Bridge, the corroded and failed tendons were all located in the same general vicinity of one another, apparently because of either material or construction issues (or both). This suggests that any tendon failures are likely to be concentrated rather than randomly distributed. Subsequent model refinements incorporated the following considerations:11,13-14

1. Different numbers of strands per tendon,

2. Different random number sets,

3. Strand/tendon stress,

4. Wire/strand strength,

5. Number of tendons,

6. Tendon length, and

7. Strand/tendon stress relaxation with time.

![FIGURE 3 Plot of Tf for wires, strands, and tendons as a function of µ(CR) (s[CR] = 0.5). FIGURE 3 Plot of Tf for wires, strands, and tendons as a function of µ(CR) (s[CR] = 0.5).](/uploads/images/2020/11/Hartt%20fig%203.png)

The Challenge Going Forward

The previous failure projection methodology is fine as a forensic tool, but its application to defining and forecasting corrosion and fracture/failure issues on actual structures requires that the present corrosion state of tendons be known in quantitative detail. Ironically, the tendon duct and grout, which are intended to provide corrosion protection to strands, also make condition assessment difficult at best.

Options that have been demonstrated to provide at least a general determination of the extent of tendon corrosion include vibration analysis,15 and magnetic flux leakage testing (MMFM).16 The former is applicable to external tendons only and is based on the principle that natural frequency of a linear member is a function of its mass and tension and decreases with decreasing tension, as occurs when wires and strands fracture. This methodology has been employed by the FDOT to qualify tendons in the general vicinity of one that has failed.

The MMFM technology, on the other hand, is based upon the principle that, when steel strand is magnetized to saturation, the resultant magnetic flux is proportional to the metal cross section area and, hence, is reduced in proportion to the extent of corrosion loss and any wire/strand fractures at a given location. It has been shown to be applicable to internal as well as external tendons, albeit not with the same sensitivity as for the latter case. A forthcoming Federal Highway Administration publication provides a comprehensive review of these and other tendon inspection methodologies.17

In addition, tendon corrosion concerns have led to design changes for integrity, inspectability, and remediation. These include redesign of anchorages with ports that facilitate internal fiber optics inspection and, if necessary, vacuum grouting of voids. Also, FDOT now requires that design for new bridges includes an additional tendon beyond what is structurally required. For such situations, loss of a tendon does not require bridge closure. In addition, a revised deviator design facilitates more safe removal of a tendon, should this become necessary.

1 In lieu of grout, flexible fillers (grease, wax, or gel) have been employed in some instances.

Acknowledgment

The author is grateful to the Federal Highway Administration for financial support of portions of this research through Grant No. ENCINC Subcontract ESC14-28.

References

1 ASTM A416/A416M-18, “Standard Specification for Low-Relaxation, Seven-Wire Steel Strand for Prestressed Concrete” (West Conshohocken, PA: ASTM, 2018).

2 L. Bertolini, M. Carsana, “High pH Corrosion of Prestressing Steel in Segregated Grout,” Modeling of Corroding Concrete Structures, C. Andrade, G. Mancini, eds. (Dordrecht, Netherlands: RILEM, 2010).

3 M. Carsana, L. Bertolini, “Characterization of Segregated Grout Promoting Corrosion of Posttensioning Tendons,” J. of Materials in Civil Engineering 28, 6 (2016): p. 1.

4 R.G. Powers, A.A. Sagues, Y.P. Virmani, “Corrosion of Post-Tensioned Tendons in Florida Bridges,” Proc. 17th U.S.-Japan Bridge Engineering Workshop (Tsukuba, Japan: Japan Public Works Research Inst. Technical, 2002): pp. 579-594.

5 W.H. Hartt, S. Venugopalan, “Corrosion Evaluation of Post-Tensioned Tendons on the Mid-Bay Bridge in Destin, Florida,” Florida Department of Transportation, January 2002.

6 V. Gouda, “Corrosion and Corrosion Inhibition of Reinforcing Steel: I. Immersed in Alkaline Solutions,” British Corrosion J. 5, 5 (1970): p. 198.

7 V. Gouda, W.Y. Halaka, “Corrosion and Corrosion Inhibition of Reinforcing Steel: II. Embedded In Concrete,” British Corrosion J. 5, 5 (1970): p. 204.

8 W.H. Hartt, S-K. Lee, “Corrosion Forecasting and Failure Projection of Post-Tension Tendons in Deficient Cementitious Grout,” Federal Highway Administration, FHWAHRT-17-074, April 2018.

9 S-K. Lee, J. Zielske, “A FHWA Special Study: Post-Tensioning Grout Chloride Thresholds,” Federal Highway Administration, FHWAHRT-14-039, May 2014.

10 W.H. Hartt, S-K. Lee, “Projecting CorrosionInduced Bridge Tendon Failure Resulting from Deficient Grout: Part I—Model Development and Example Results,” Corrosion 72, 8 (2016): p. 991.

11 W.H. Hartt, S-K. Lee, “Modeling and Projecting the Onset and Subsequent Failure Rate of Corroding Bridge Post-Tension Tendons Arising from Deficient Grout,” Corrosion 74, 2 (2018): p. 241.

12 W.H. Hartt, et al., “Long-Term Effects of Cathodic Protection on Prestressed Concrete Bridge Components,” Federal Highway Administration, FHWA-RD-98-075, April 1998.

13 W.H. Hartt, “Effect of Modeling Variables upon Projection of Corrosion-Induced Bridge Post-Tension Tendon Failures,” Corrosion 74, 7 (2018): p. 768.

14 W.H. Hartt, “Failure Projection of Corroding Bridge Post-Tensioning Tendons Considering Influential Factors and Issues,” Corrosion 75, 9 (2019): p. 1,146.

15 A.A. Sagüés, S.C. Kranc, T.G. Eason, “Vibrational Tension Measurement of External Tendons in Segmental Posttensioned Bridges,” J. of Bridge Engineering 11, 5 (2006).

16 S-K. Lee, et al., “Development of Magnetic Flux Based Nondestructive Evaluation Technologies for Detecting Corrosion Damage in External and Internal Post-Tension Tendons,” Federal Highway Administration, FHWA Draft Report, March, 2019.

17 S-K. Lee, “Corrosion-Induced Durability Issues and Maintenance Strategies for Post-Tensioned Concrete Bridges,” Federal Highway Administration, FHWA Report to be published.