Correctly classifying the corrosivity of environmental conditions is one of the most crucial components of asset management. Accurately assessing the environment for corrosion ensures infrastructure owners can optimize their maintenance budgets while improving safety and reliability. This can reduce risk and save infrastructure owners millions of dollars a year.

For over 20 years, coating manufacturers have been specifying protective coating systems to meet the standards of ISO 12944 with limited ability to assess atmospheric conditions over a broad geographic area.

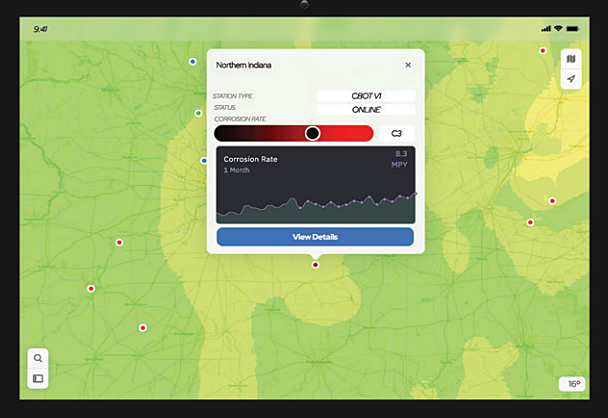

Engineering Director, Inc. (EDI), with data supplied through AtmosphericIQ LLC, created a web application that makes it easy to assess atmospheric exposure to specify the optimum coating system based on desired life expectancy. They have also developed an IoT corrosion sensor CBOT™, that can capture atmospheric data in real time.

The History of Atmospheric Corrosion and the ISOCORRAG Program

So why is a global lookup tool needed to understand an environment’s atmospheric corrosion growth rate? “This dates back to the 20th century, to a program called ISOCORRAG—international atmospheric exposure program, which turned out to be the largest collection of atmospheric corrosion and environmental data ever published in a single source,” says Joe Mazzella, president of EDI. “They exposed panels for over 12 years in Europe, North America, and Asia. This program was later followed up by a program called MICAT, which covered Central and South America.”

Thirteen countries participated in the exposure program, totaling 53 sites that included industrial, urban, rural, marine, and coastal locations in temperate, tropical, Arctic sounds, and other environments. The ISO922X-class of standards developed from this global program, “I think the ISOCORRAG program is, by itself, super interesting,” says Tom Hayden, CTO of EDI. “All this research was done in the 70s and 80s through the Iron Curtain. So, academics in the USSR and here in the United States, Canada, and South America were studying atmospheric corrosivity.”

After exposure, they measured the mass loss and correlated it to atmospheric parameters to generate response functions to predict corrosivity. “It’s an exciting project and pivotal to corrosion professionals,” explains Hayden. “ISOCORRAG is the first real project for all of mankind, where everyone was on the same team to attempt to address atmospheric corrosion.”

The final result, ISO:9223-1992, was the first global standard for providing guidelines for categorizing and classifying the corrosivity of atmospheres. This standard offers five categories assessing atmospheric corrosion, C1 for indoor environments to C5/CX for the harshest marine environments. In conjunction with ISO:12944-1992, it provided corrosivity estimates specific to protective coating systems related to life expectancy, known as durability ranges. Both standards have changed over time, the most current being ISO 9223:2012 and ISO 12944:2017.

“Many coating manufacturers and professionals worry about painting an architectural surface, painting the outside of a pipeline, how much coating they should put on, what type of coating,” explains Hayden. “That’s what feeds into all these standards.”

“Additionally, it influenced our algorithms, too,” Mazzella notes. “When we put our atmospheric algorithm together, based on atmospheric data, it influenced us, too, and the way we work our model and how we calibrate our models along the way.”

Industry Adoption of ISO Standards Related to Atmospheric Corrosion

Over time, engineers began specifying high-performance requirements around the ISO:9223 and ISO:12944 standards, while protective coatings managers, likewise, started specifying products based on these standards.

“The significance of an ISO:9223 C1 through C5 lookup tool [developed by EDI] is that the industry never found an easy way to classify the atmospheric environments on a global scale,” Mazzella says. “If you are a protective coating manufacturer and a customer calls, typically everybody’s making phone calls to the lab and at times all over the world trying to figure out what that environment is. They’re wasting and spending a lot of time that does not need to be spent.”

AtmosphericIQ provides the GIS architecture for the tool, along with high-resolution data and feeds of real-time and historical atmospheric data. Before the C1 through C5 lookup tool, many people adopted a myth that 1 mile (1.61 km) from a coastal body of water was a C5 environment (the harshest environment). When, in fact, a seaside community can range from C2 to C5, implying the coating system, in many cases, was overbuilt to the environment, costing owners significantly more money and time.

The C1 through 5x lookup tool is designed around the needs of owners, operators, and engineering companies. All of which can have significant protective coatings construction and maintenance budgets. Along with this comes the need to understand the rate of corrosion based on atmospheric exposure.

Mr. Mazzella explained he has worked with owners with hundreds of above-ground facilities of various sizes where the degree and rate of corrosion can vary significantly based on location. The inability to efficiently and cost-effectively classify the rate and degree of corrosion for atmospherically exposed steel assets can significantly impact owner life-cycle costs.

Owners have a limited ability to proactively assess, monitor, and manage corrosion (risk) of assets over a broad geographical area without applying unpractical and costly methods, such as running expensive exposure programs. Fortunately, we have decades of research and data thanks to the hard work during the ISO-CORRAG program and new technology coming on the market.

To validate their findings based on weather data, they placed solar-powered atmospheric sensors in several microenvironments in North America, including offshore, to measure components of ISO 9223 (SO2, Cl, Temperature, Relative humidity). While at the same time, also setup up metal panel racks at the locations to validate the corrosion rate.

IoT Sensor Monitors Corrosion Rates in Real Time

EDI and data supplied through Atmospheric IQ LLC have developed their own inexpensive, lightweight IoT sensor for interpreting the C1 through C5 environment and microclimates. “This is what we’re going to be launching this year,” says Mazzella. “We’ve devised a cost-effective IoT sensor that we’re calling CBOT™ for Corrosion Monitoring for under $1,000 that can be placed anywhere. You can stick them on with magnets or brackets, and they have connectivity, so they report home in real-time and monitor corrosion.”

The sensors can be easily attached anywhere and inform the asset owner of the corrosion growth rate. “Then you can do the math and answer the question: What is my lifespan estimate? How often do I have to recoat this? And very narrowly forecast when they have to paint next, when they have to do different treatments, and so on,” says Hayden.

“Right now, we have this product where you put in your address and see the corrosion rate,” he adds. “But there will be some error associated with that, and if you want to narrow down and improve your error bars, that’s where the sensors come in.”

Mazzella and Hayden say this technology will help more than most people realize. “The grand trajectory of how this technology is working is… when you when you think about 20 years ago, nobody knew what their atmospheric environment was,” explains Hayden. “You had to guess or put out expensive racks. There’s a step in between, which is the software we’ve developed [ISO 9223 C1 through 5X lookup tool], where we can step back and look at a large area and say, ‘Here’s what I think my rate is the in the area of X, Y, and Z.’”

The next step, if you are unsure of your area, is to use an IoT sensor. “If you have an area where maybe you don’t feel confident, or you’re next door to a power plant, or you’re right next to the ocean or something, that’s where the sensors come in,” says Hayden.

EDI has had to design custom steel electrodes specifically for these sensors, “the folks who print PCBs don’t work with steel, so we’ve invested in a corrosion electrode manufacturing operation,” Hayden says, “We’re hoping to be part of the Federal CHIPS program funding this year.”

Hayden notes, “AMPP’s actually been playing a big role in all in all of this.” The AMPP SC 13 Corrosion Monitoring and Measurement Standards Development Committee has developed a related standard, ISO22858, which governs how to estimate atmospheric corrosion as a function of electrochemical responses in the electrode used in the sensor.

“We’re building our sensors up to these standards developed by AMPP,” he says. “It’s been a leap forward for our business having access to this level of research.”

Conclusion

They’re not the only technology company interested in developing IoT corrosion sensors. At least two other groups are nominated for AMPP Technology Awards for similar corrosion sensors. As more companies move towards automation, having sophisticated monitoring technology in the field is a critical requirement.

This is notable in the underground corrosion space, as the number of firms offering remote monitoring units (RMUs) has proliferated in the past few years.

Understanding the local atmospheric corrosion levels in real-time is a game changer for asset owners. “This effort is a continuation of a lot of the work people have already done,” Hayden concludes. “So much amazing corrosion research was done in the 20th century, and we’re sort of taking it and applying a lot of digital technology to it.”

Source: EDI, www.engineeringdirector.com.