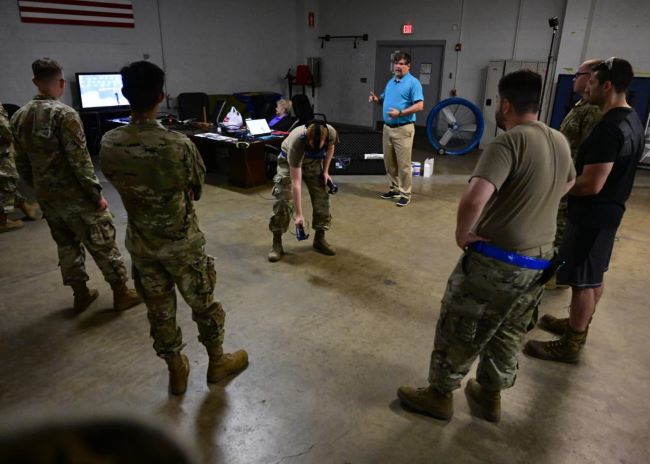

At Little Rock Air Force Base, Arkansas, USA, the 19th Maintenance Group and a project team from the 19th Maintenance Squadron recently tested new virtual reality (VR) corrosion control capabilities to train Airmen in a more controlled environment.

The VR simulation allows Airmen to immerse themselves in a hangar containing an aircraft and use a controller that is modified to look and feel like a paint sprayer to paint the aircraft and various parts.

According to the Air Force, the push for the VR training helps reduce the costs and risks associated with Airmen using real paint and tools.

“For the fabrication flight to produce the level of work required, hundreds of hours of training are necessary, along with gallons of paints and solvents,” says Tech. Sgt. Matthew Rollason, innovations non-commissioning officer in charge for the 19th Maintenance Group.

In addition to monetary and safety benefits, the VR training allows the Airmen to train at virtually anytime and anywhere they want.

“The simulator will provide customizable training for the Airmen of the 19th MXS without the need to practice on costly aircraft parts and rely on aircraft repair schedules,” Rollason says.

With the technology already implemented at Naval Air Station Pensacola, Florida, USA, and at Warner Robbins Air Force Base, Georgia, USA, Airmen from the 19th MXG and MXS teams are looking to expand the scale and scope of the VR capabilities.

“This has been a long project,” says Tech. Sgt. Brian Welch, 19th MXS corrosion control shift leader. “As we expand on this concept, we believe the benefits to our Airmen will be worth all the effort we have put into getting this implemented as a standard for our unit.”

Source: U.S. Defense Visual Information Distribution Service, www.dvidshub.net.