NACE International (now AMPP) accepted pipeline current mapping as a standard (SP0502-210)1 a few years after the practice was introduced.

This methodology, which has been extensively utilized and designed through the collaboration among several gas companies, involves evaluating the coating of a pipeline from aboveground. This is accomplished through the use of electromagnetic techniques.

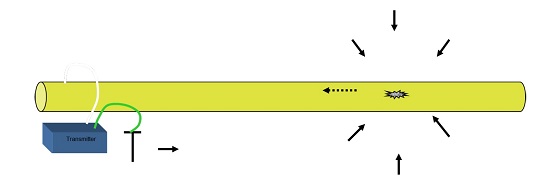

Pipeline current mappers are composed of three parts (Figure 1): a transmitter (for using the AC and DC current), an electromagnetic receiver (to display signal strength, measure current flow, and measure the depth to the center of the pipe), and an accessory that measures DC voltage gradient.

Types of Surveys

According to researchers Whitney Williams and Peter Mann in their 2022 AMPP Annual Conference + Expo paper upon which this article is based,2 pipeline mapper systems have the ability to perform the following surveys: depth of cover, current attenuation, and AC voltage gradient, as well as locating pipelines, cables, and shorts on distribution.

Several AC current signals are sent to the pipe in order to conduct the surveys. An AC current with <1KHz frequency can locate the pipe and measure the depth to the center, and one with <10Hz can imitate the cathodic protection current used on the pipeline. The operator can also identify multiple coating defects along the length of the pipe or connections to unwanted conductors.

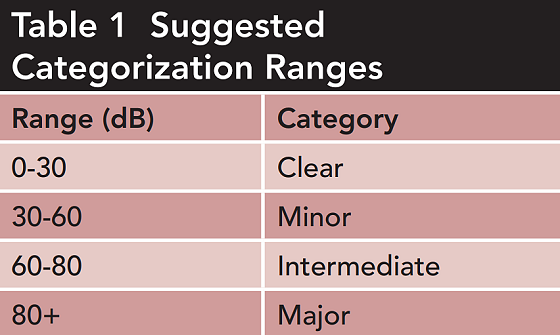

The researchers note that the AC current attenuation (ACCA) survey can identify areas in need or additional examination, while the DC voltage gradient (DCVG) survey can locate and categorize defects based on severity of coating degradation. An A frame is used in DCVG surveys that measures the voltage gradients around coating defects; the higher the measured voltage, the more metal is exposed to the soil (Figure 2).

Pipeline Mapping in the Field

Fieldwork using pipeline mapping was performed in two locations in Peru. In the first, a 1-km section of pipe was surveyed using ACCA and DCVG.

The pipe ran through mountainous desert terrain, and although there were substantial changes in elevation, no noteworthy defects were identified (Figure 3, bottom). Close interval tests previously completed aligned with the results from the ACCA and DCVG data.

The second location included a 500-m section of pipe, which was also surveyed using ACCA and DCVG. This particular section of pipeline was believed to contain defects. As with the first location, a close interval survey had been conducted, but in this one, a defect was suspected. The pipeline mapping system verified these results and found the defect to be major.

Conclusions

Pipeline current mapping is a successful means of evaluating the coating system of pipelines under all types of conditions and terrains.

References

1 NACE SP0502-2010, “Pipeline External Corrosion Direct Assessment Methodology (Houston, TX: AMPP, 2010).

2 W. Williams, P. Mann, “Tips and Tricks When Evaluating Pipeline Integrity,” AMPP 2022, paper no. 17617 (Houston, TX: AMPP, 2022).