Earlier this year, a refinery in the United Kingdom identified unexpected corrosion in its delayed coker fractionator column during a planned turnaround.

Delayed Coker Fractionator Column

Coker or fractionator vessels are part of a refinery’s mission-critical equipment, and they operate at approximately 370 °C. They create usable fractions from heavy gas oils. This vessel was built in the 1970s and had an internal Type 400 stainless steel cladding installed as new.

Protective Cladding Embrittlement

The challenge with the cladding was that after a long time in service, it was heavily embrittled. Performing welding in the region where the cladding was installed led to cracking. Cracking unsurprisingly resulted in the failure of the vessel's protective barrier.

Problem Areas

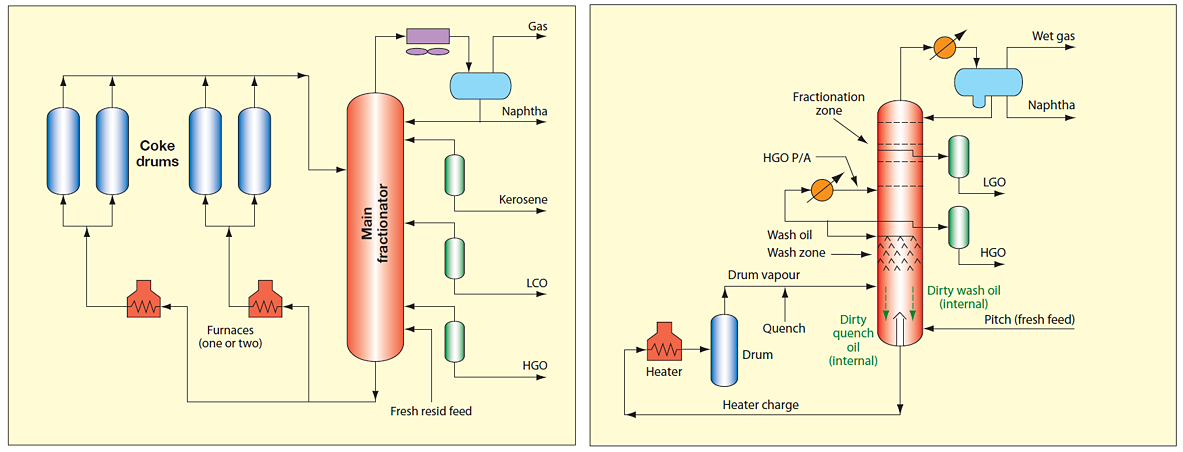

The column has two sections. The upper section is the fractionation zone, where there are offcuts of the different fractions of material as they boil off, and then the lower section is a wash zone.

The main problem areas included a nozzle in the lower section and two small nozzles up in the fractionation zone of the column, which also had relatively small but significant localized damage just around the inlets to the nozzles. This is believed to be caused by erosion-corrosion of the existing cladding exposing the underlying carbon steel (CS).

Welding the Vessel

Upon an initial inspection, refinery maintenance personnel planned to weld it up. Welding would create heat-affected zones, and it would not be possible to do post-weld heat treatment without putting too much heat into the local area, leading to further cracking of the existing internal cladding. They considered evaluating field weld overlay with a specialized weld overlay process.

Still, due to the short-term notice of the discovery scope, it was not possible to consider setting this up in time without extending the critical path of the outage. They had an issue.

Previous Repairs of Last Turnaround

One of these nozzles has caused problems previously. So the maintenance department performed a cut-and-weld of the nozzle in 2015. First, they cut a window out of the vessel's side and welded an insert plate with a nozzle welded to it.

“They had this 50-mm, approximately 2-inch band around the new protected insert, which was essentially exposed carbon steel,” says Colin Bateman, a corrosion mitigation expert at Integrated Global Services (IGS) (Richmond, Virginia, USA).

When they returned in 2021, they found that this exposed area had suffered heavy corrosion and deep pitting, which needed to be addressed. Plan A was to cut and remove the existing plates, but effectively they would have the same problem.

“They were going to have the same issue of not being able to weld buildup the corrosion-resistant alloy overlay to overlap it onto the existing cladding, because any welding would have caused further cracking,” Bateman explains.

Evaluating a New Solution: HVTS

Upon receiving a referral from their sister company in the United States, they considered the use of high-velocity thermal spray (HVTS). The key advantage of using HVTS is that it does not create heat-affected zones. The low level of heat input into the vessel to carry out the work would not cause any issues with the existing cladding.

After being initially skeptical of “thermal spray,” the site’s engineers, planners, integrity team, and an inspection team evaluated laboratory reports provided by IGS, the developer and turnkey provider of the HVTS solution.

Cyclic temperature testing was important due to the column's operation. Case histories were also evaluated, focusing on examples of the long-term performance of the system. Additional test results were shared demonstrating the performance of HVTS in high-temperature sulfidation and naphthenic acid corrosion environments, as these existed inside this coker fractionator column.

Works Commenced During 2021 Shutdown

When they cut out the old plate, more damage was caused. They believed this to be due to residual stresses in the column from the previous welding of the external circumferential support bands.

As a result, the repair area was extended, and a bigger plate was fabricated to cover the damaged areas. Discrete heavily pitted areas required local CS weld buildup to return the pressure boundary to the required thickness.

HVTS Application

IGS had the equipment and materials in the country, and thus was able to support the refinery with a fast application of HVTS, meeting their turnaround schedules.

HVTS was applied to seamlessly connect the Alloy 625 overlay on the new insert and the existing Type 400 cladding in the vessel by overlapping both corrosion-resistant alloy (CRA) materials.

All safety and quality control procedures were followed, including monitoring the surface preparation, cleanliness profile, and taking thickness measurements of the HVTS during application.

Swiftly Solving a Problem

Going from potentially having to extend a planned turnaround to completing all the work without costly interventions was welcomed by the refinery. The solution was applied only two weeks after the initial issue was discovered and will be continuously monitored until the next shutdown in four to five years.

“The shutdown coordinator was very complimentary about IGS’ operational performance, professionalism, and technical knowledge and will be sharing the details of this project with their sister sites,” Bateman says.

As such, HVTS has proven its effectiveness in columns, towers, vessels, and boilers, according to the services provider. This includes protecting exposed CS, as well as existing CRA cladding or overlay. As an experienced turnkey solution provider, IGS says it delivers projects across the globe and can mobilize quickly in case of emergencies.

Source: Integrated Global Services (IGS), www.integratedglobal.com.