Thermal spray zinc (TSZ) coatings have proven to be very durable. Since first patented in Germany and Switzerland by Max Schoop in 1909,1 TSZ coatings have been used around the world to successfully extend the lives of steel bridges. In the United States, the Kaw River Bridge in Kansas City, Missouri was thermal sprayed with 250 to 300 µm of pure zinc in 1936 and when last inspected in 1975, the coating was found to be still in good condition.

The Ridge Avenue Railway Bridge in Philadelphia, Pennsylvania was thermal sprayed with 250 µm of zinc the following year in 1937. This bridge was subject to very aggressive environments from the steam and diesel locomotive exhaust as well as from deicing salt fogs from the road underneath, yet the TSZ coating was still protecting the bridge 55 years later in 1992.2

TSZ duplex coatings were used to protect the Vilsund Bridge, which crosses a strait in the Limfjord in Denmark, in 1939.3 The riveted five arch steel bridge sits very close to the water in an aggressive marine environment where the bottom sections of the bridge are in the splash zone. The bridge was completely rehabilitated in 1979 after 40 years to remove the original lead-based paint and reapply a TSZ duplex coating with an alkyd topcoat. The bridge was again recoated after 34 years in 2013, to replace the paint coating. The TSZ coating was in good condition and patch paint repair was an option; however, the new paint topcoat was not compatible with the old alkyd paint system. The bridge was fully recoated with a new TSZ duplex coating.

Similarly, the Auckland Harbour Bridge in New Zealand was protected from corrosion with a TSZ duplex coating in 1958. The bridge was thermal sprayed with 50 µm of pure zinc and then coated with a three-coat phenolic paint system.4 In 1961, the Forth Road Bridge in Scotland was protected with 125 µm of pure zinc covered with a three-coat paint system. At that time the bridge was the largest structure in the world to be coated with a TSZ duplex coating. The Pierre Laporte Bridge, which crosses the St. Lawrence River in Quebec, Canada, was the largest ever field metallizing project in the world. In 1977, over 160,000 m2 of surface were covered with TSZ.2

The Norwegian Public Roads Administration (NPRA) first tested TSZ duplex coatings on the Djupfjord Bridge near Lofoten in 1958. This small suspension bridge was coated with 150 µm pure zinc with a two-coat paint system. Then in 1965, inspired by the Forth Road Bridge, it was mandated that all new highway bridges in steel be protected with TSZ duplex coatings, as no other protection comes close in terms of durability.5

The NPRA expects a coating life of 35 years before first maintenance, and then preferably only the paint topcoat shall be renewed. That is, no blast cleaning to base metal, but only power washing of the paint layer. By taking preventative action to repair only the paint, the TSZ base layer will not corrode, and is applied only one time. During the 100-year design lifetime of a bridge, ideally there will be only two maintenance operations after 35 and 70 years where the paint topcoat is renewed.3

A coating performance indicator (CPI)6 shows that many bridges in Norway may realize their full design life without maintenance. The most important factor in determining coating life is the quality of the coating. Application errors like spitting, pinholes, and low paint film thickness were responsible for the observed coating failures. These errors decrease the protective properties of the paint film and hence, the overall life of the coating.

Thermal Spray Zinc

TSZ can be applied by either electric arc spraying or flame spraying.7 For each process, the steel surface needs to be prepared for thermal spraying. Grit blasting of the steel surface is required to provide adequate mechanical adhesion of the sprayed zinc coating to the steel.

The flame spray technique uses an acetylene-oxygen flame to melt a zinc wire or powder that is continuously fed into this flame. A stream of gas, generally compressed air, then propels the molten metal droplets in the direction of the steel surface. For the arc spraying technique, two zinc wires are brought together at an angle between 30 and 60 degrees, and an imposed voltage difference between them creates an electric arc. A gas flow, of either compressed air or a special gas, then atomizes and propels the molten metal droplets toward the steel substrate.

The deposition of semi-solid droplets on a roughened steel surface produces a metallic zinc layer with micro-pores that typically make up 5 to 7% of the coating volume. The thickness of the thermal spray coating is dependent on the time of spray. For duplex coatings, the metallic zinc base layer is usually 100 µm thick. The TSZ coating has a rough surface, which is excellent for paint adhesion and characteristics similar to solid metallic zinc, including a Vickers hardness of around 70.8

Pure zinc coatings for corrosion protection of steel were first applied by thermal spray over 100 years ago. Now the zinc-15% aluminum alloy coating, developed in the 1970s, is the alloy coating of choice for the most severe environments. A comparison of the melting rates for pure zinc and the zinc-15% aluminum alloy between the flame spray and arc spray techniques also shows an increase in deposition efficiency and coating rate with the arc spray process.9

Duplex Zinc Coatings

Paint on top of a metallic zinc coated steel is called a “duplex” coating. The significant extension of the expected life of the combined zinc-paint duplex coating compared to the sum of the expected lives of the zinc coating or the paint system used by themselves is known as a synergistic effect.10 The paint topcoat provides extra barrier protection for the zinc, but the main reason for the synergy is that the metallic zinc coating protects the paint from underfilm corrosion creep at scratches or holes. The synergy effect between the two coating systems can extend the total life of the coating from 1.5 to 2.3 times, depending on the environment. The synergy effect can be defined by a factor in Equation (1):

TSZ Duplex Coating Performance in Norway

NPRA has specified TSZ duplex coatings for protectionof steel bridges since 1965. Most of the steel bridges in Norway cross rivers or fjords along the seacoast and are exposed to a corrosive marine environment with an ISO corrosivity classification of C3 to C5. Inland bridges are in a more benign environment classed as either C2 or C3. The ranking of the atmospheric environment for steel bridges in Norway is mostly based on the navigation clearance above the water and the water type (fresh or salt), with road deicing salt loading and local wind conditions also contributing.

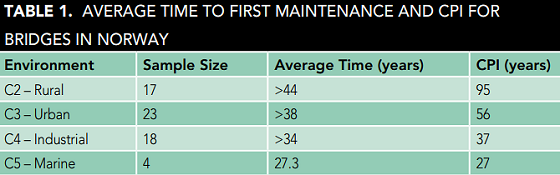

From a survey of maintenance records from 62 long-span steel bridges built between 1967 and 1995,6 the average time to first maintenance for bridges located in various environments has been calculated. Since most of the bridges studied have not yet been repaired, the average time to first maintenance will continue to increase each year. In order to estimate an expected life of the coating before first maintenance, a CPI was calculated.6 The CPI considers the life of the coating, the condition of the coating, and the environment classification to give an indication of the expected life of the coating before first maintenance.

where L is either the present age of the coating, or the time until the coating was repaired; C is the corrosivity category number (Category 2–5); and S is the assessment of the condition of the coating as either good (3), fair (2), poor (1), or repaired (0). Therefore, for repaired coatings, the CPI will be equal to the coating lifetime. For coatings that have not yet been repaired, the CPI will be the current age of the coating with an additional expected life proportional to the current age and condition, and inversely proportional to corrosivity.

The average times to first maintenance along with the CPI are presented in Table 1. As expected, the average time to first maintenance is shorter in more corrosive environments. However, the TSZ duplex coatings are exceeding expectations in C2 and C3 environments and meeting the expected life of 35 years in the C4 environment. Since most of the bridges in these environments have not yet been repaired, the average time to first maintenance continues to be extended each year. The bridges in the most severe marine environment (C5) have all been repaired and so the average time to first maintenance is fixed at 27.3 years. However, the sample size for this classification is very small, two of the four bridges had premature repairs, and so the results are considered conservative.

The CPI results were surprisingly positive. For example, in a C2 environment, it appears possible for a TSZ duplex coating to approach the 100-year design life with no maintenance. Similarly, bridges in the C3 environment may only need coating maintenance repair one time to reach the 100-year life. Bridges in the C4 category will meet the expected maintenance plan. More data will make the CPI more robust, especially for the C5 environment.

Coating Quality

Thermal spraying and painting are well known processes, but both the zinc and the paint must be properly applied to achieve a long-lasting TSZ duplex coating. There are a few key quality criteria that must be fulfilled to achieve good coating quality.

For thermal spraying, skilled applicators and metallizers are needed to avoid a defect known as “spitting.” Spitting is the incomplete melting of the zinc wire, which results in peaks in the zinc coating that will penetrate the paint coating and become sites for corrosion initiation. If spitting is observed, the TSZ coating can be easily repaired with simple sanding before painting.

TSZ coatings are sealed before the application of the topcoat. The sealer coat must be applied very thin to avoid pinholes in the paint film. Ideally, the sealer should not build thickness and a maximum of 25 µm is therefore specified. If the sealer is applied too thickly, bubbles may form. When the paint layers are applied, the bubbles break, leaving pinholes through to the base zinc layer. If bubbles are observed in the sealer coat, again, the solution is to sand the sealer coating to remove the bubbles. There is no need to remove, or reapply, the sealer coat.

The most common quality issue is the paint film thickness does not meet specification. Standard thickness gauges will only measure the total film thickness including the zinc coating. High zinc film thickness may then mask low paint thickness. Measuring the coating thickness of the zinc and the paint as they are applied is recommended to ensure adequate paint thickness that meets specifications. However, modern epoxy coatings require a certain wet film thickness before a uniform film is formed, so this will be less of an issue as the painter is now able to see when sufficient paint is applied.

Conclusions

• TSZ duplex coatings have been used successfully for decades to mitigate corrosion in atmospheric exposures on steel bridges in Norway.

• The synergy between the two coatings provides protection beyond the expected life of each layer individually.

• The TSZ duplex coatings on average easily meet the NRPA required 35-year life before first paint maintenance in C2, C3, and C4 environments.

• The CPI shows that TSZ duplex coatings may realize their full design life in C2 environments with no maintenance.

References and About the Authors