Erosion and scouring, among other sources, can lead to pipeline exposure when pipelines cross bodies of water. Even if these pipelines were adequately covered at one time, they are at risk for partial or full exposure due to water actions. Lakes, ponds, rivers, swamps, etc. that cross pipes cause loading by water pressure, moving objects in the water, and sometimes cyclical vortex induced vibration, which are all known causes of pipeline failure. Once exposed, pipeline coatings are at additional risk from third-party events or UV [ultraviolet] damage.

To avoid pipeline operator liability, and keep people, the environment, and related resources safe from events such as erosion, scour, dredging, debris, and floatation, it is important to follow applicable regulations and codes.

An advisory bulletin was recently released by the U.S. Pipeline and Hazardous Materials Safety Administration, encouraging owners and operators to implement corrective actions, like inspections, after a water event. In addition to inspections, monitoring and autonomous surface vehicles can be of aid.

River scour occurs when a riverbed/riverbank is eroded by moving water, either progressively (with time) or abruptly (due to a flood). River Scour Monitoring (RSM) systems, through the use of temperature sensing, have proven effective in detecting exposed pipe and the degree of pipeline scour. Identifying scour early on is key because once a pipeline is uncovered, it can be damaged in multiple ways.

By analyzing two case studies, researchers V. Shankar, C. Onuoha, E. Pozniak, S. McDonnell, and M. Jawed of PureHM (Nisku, Alberta, Canada) offer “easy, effective, and consistent methods to identify and verify an exposed pipeline in a watercourse crossing” in their C2020 paper.1

Because finding failures during a flood or other event is difficult and unlikely, remote monitoring systems can be invaluable due to the real-time information they offer. Figure 1 shows pipeline failures from water actions, along with the sub-cause of each and Figure 2 shows the ideal RSM system.

It is vital to establish baseline conditions prior to setting up the RSM system. This way, any changes can be easily identified. Baseline measurements should include:

• Depth of water

• Depth of cover

• Elevation

• 3D geospatial positioning

• Bathymetric profile

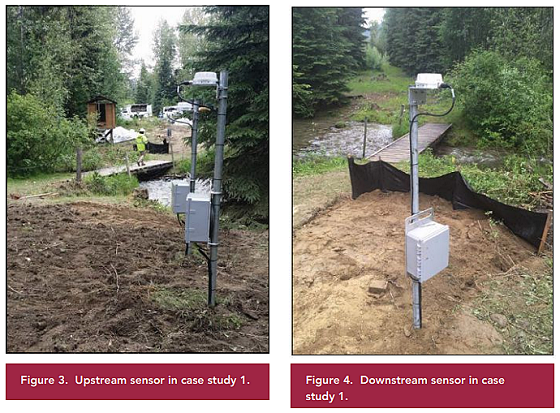

In the first case study, the researchers validated the technology on a pipeline at two creek crossings (North Crossing and South Crossing). Three sensors were positioned at each crossing—two upstream and one downstream (Figures 3 and 4)—and each has a temperature sensor and an acoustic sensor. In the study, the sensors were charged using external charging at three-month intervals, but recent systems have since been updated with solar panels. Data is collected in real time and communicated to analysts via satellite for review.

The study revealed that no exposed pipe occurred at the North Crossing. By taking the temperatures recorded on both upstream sensors and calculating the rate of change, the researchers were able to forecast the temperature at the downstream end. Assessing the predicted vs. actual temperatures showed no deviation, and a visual inspection took place that confirmed there was no pipe exposure.

However, the South Crossing did result in pipe exposure. This time, when actual and predicted temperatures were compared, they revealed a considerable difference. When examined visually, the exposure was discovered. This substantiated the technology’s ability to correctly identify exposed pipe at water crossings. The scientists emphasize that product flow is a foremost prerequisite to properly use this technology because, “The measured temperature on the pipeline is primarily due to the product, and rate of change of temperature is due to the product flow from one location to another and thermal equilibrium between pipe, soil, and water.”1

Pipe exposure also occurred in the second case study, which was validated through indirect inspection survey. After extensive flooding was observed onsite, a bathymetric survey was conducted. M2B sonar mounted on a boat revealed 68 ft (20.7 m) of exposed pipeline. A “touchdown point” identified in the middle enabled the researchers to reduce the length to two smaller sections—one 16 ft (4.88 m) and one 36 ft (10.97 m).

In conclusion, managing pipelines at water crossings through the use of RSM technology can reduce contamination, save lives, and prevent damage to the environment. By incorporating RSM technology, integrated direct inspection technology, plus autonomous surface vehicles, operators have successful, reliable information with which to validate exposed pipe.

Reference

1 V. Shankar, et al., “Monitoring and Assessing Pipeline Water Crossings in the Face of Severe Flooding, River Scour, and River Channel Migration,” C2020, paper no. 14962 (Houston, TX: NACE International, 2020).