The harsher the conditions a structure is exposed to, the greater the need for corrosion control and maintenance measures. These conditions often occur in offshore industries, where installations are subjected to continuous or recurrent water immersion.

Coatings have been developed to protect against ocean water, waves, and tides, as well as other environmental factors, including wind and ultraviolet radiation. Such coatings are used frequently on oil and gas rigs and platforms, including smaller components, like walkways, pylons, and pipes.

Coatings applied in splash and immersion zones are regularly applied to damp/wet substrates, or they might even be submerged soon after application. These short timeframes and less-than-ideal conditions add to the complexity of application and necessitate additional analysis.

Historical Limitations

Related standards, such as NORSOK, while helpful at providing information about a coating’s corrosion resistance capability, do not always provide information regarding substrate surface and cure time, which can influence the coating’s performance.

Accordingly, researchers T. Doan, N. Rakers, M. Shearer, M. DiTucci, J. Begley, X. Gu, and A. Mubarok1 with PPG (Allison Park, Pennsylvania, USA) set about to study two coatings—cured for two weeks in both air and underwater—and their adhesion abilities in various conditions. Identifying the effect of the coating’s curing environment on its bond to the substrate was their primary objective.

Over time, new coatings have been created that offer better surface tolerance and underwater curing. They are commonly composed of binder resin, pigment, filler, solvent, and additives. Traditionally, coatings utilized in splash, tidal, and immersion zones have contained epoxy amine resin, which bonds with the substrate. This enables it to hold to the substrate and cure underwater. The researchers note that care should be taken when selecting the epoxy resin and amine curing agent to avert unintended side effects.

Air and Underwater

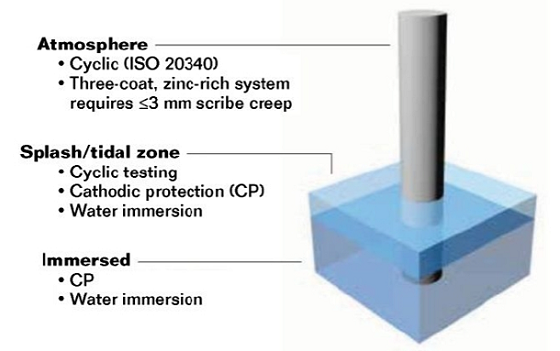

Performance standards, such as NORSOK M5012, certify that specific coatings meet certain requirements based on exposure type. This helps decision makers choose the coating that best meets their needs. An offshore installation could be exposed to three different conditions, including atmospheric, splash/tidal zone, and immersion (Figure 1).

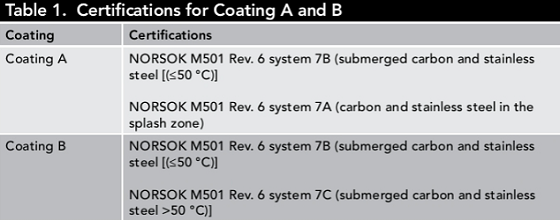

The experts studied two coatings from two suppliers (Table 1). They identified the cure time for the coatings in both air and underwater to ensure their adhesion strength data was correct. In addition, they examined the adhesion properties of both coatings on multiple substrate surface conditions.

These conditions included: salt fog, constant 100% relative humidity (at 49 °C), acidified synthetic seawater immersion, deionized (DI) water immersion, or non-exposed panels (used as a control). These tests were also performed in air and underwater. Mechanical testing, near-infrared spectroscopy and multivariate analysis, and pull-off adhesion tests were performed.

Research Observations

The researchers observed that, on the panels that were exposed to synthetic seawater, Coating A and Coating B experienced obvious adhesion loss vs. the control panels. The greatest adhesion loss occurred using Coating B when cured underwater (vs. air) and pre-exposed to seawater. It was also noted that neither Coating A nor Coating B exhibited a significant change in adhesion when exposed to humidity and DI water immersion.

Results showed the substrate surface condition and the cure condition of the coating had a considerable influence on its adhesion performance. No noticeable difference was detected in the mechanical properties of the coatings’ free films when cured in air or underwater. The near-infrared spectroscopy testing revealed that for Coating A, whether cured in air or underwater, both progressed a cured film at the same rate.

While standards and certifications are helpful, it is also important to understand that substrate and cure conditions are also important factors to consider when making a coating selection.

References

1 T. Doan, et al., “Properties of Splash Zone and Immersion Coatings,” CORROSION 2020, paper no. 14634 (Houston, TX: NACE International, 2020).

2 NORSOK M501, “Surface Preparation and Protective Coating” (Oslo, Norway: Standards Norway, 2012).