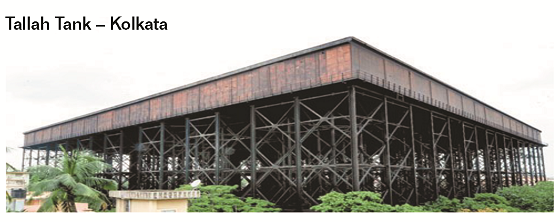

Kolkkata, India's Tallah Tank is the world’s largest overhead steel tank (Figure 1). This tank is an iconic landmark of Kolkata city, supplies water to a vast majority of the city’s population, and is under refurbishment. Supported by steel columns and girders, it is 33.5-m (110-ft) high from its ground base and can hold nine million gallons of water.

The Tallah Tank was built in 1909 on 1.21 ha (3 acres) of land to supply filtered drinking water to the residents of Kolkata. When full to its brim, the tank and support structure weighs 44,000 metric tons (48,500 tons), which is more than the weight of the Titanic (41,730 metric tons [46,000 tons]). The water itself weighs ~36,300 metric tons (40,000 tons) and the structure weighs 8,500 metric tons (9,370 tons).

The Tallah Tank was made of the same quality of steel used in the Titanic. The steel reservoir dimensions are as follows: 98 m (321 ft) in length; 98 m in width; and 33.5 m in height. The tank is 5.5-m (18-ft) deep and divided into four compartments, which are independent of each other and can be cleaned or repaired anytime without disrupting the water supply. The Tallah Tank was designed by the chief engineer of the then Kolkata Corp., W.B. MacCabe. It was fabricated by Clayton, Son & Co. from Leeds, United Kingdom. The materials, including the steel plates, were shipped from England.

The construction work on this iron and steel marvel began on November 18, 1909 in the presence of the then Lt. Governor of Bengal, Sir Edward Baker. It was commissioned on May 16, 1911. When the pumping engine from the Palta Pumping Station is not capable of supplying sufficient water to meet the demand in the middle of the day when the consumption is heavy, the Tallah Tank comes into operation.

When sufficient water is not coming down to fill the two mains, water from the tank automatically flows into those mains to keep supply equal to the demand. The tank is refilled again at night when the demand falls. The decision to renovate the world’s largest overhead reservoir was taken after engineers found some leaks due to corrosion in the steel plates of all compartments. It was decided by Kolkata Municipal Corp. to revamp/refurbish the structure as well as install new lining/coating. Funding was arranged through Atal Mission for Rejuvenation and Urban Transformation scheme and West Bengal Government funding. Figure 2 shows the epoxy mortar covering the bottom of the Tallah Tank.

Selection of Food-Grade Epoxy as Lining

NACE SP0169-2013

1 states the following properties and other factors are considered for selection of lining during recoating:

a) Nontoxic to potable water

b) Effective electrical insulator

c) Effective moisture barrier

d) Applicable on mild steel surface with a minimum of surface defects

e) Ability to resist development of holiday with time

f) Ability to resist damage during handling, storage, and installation

g) Ability to maintain substantially constant electrical resistivity with time

h) Resistance to disbonding

i) Resistance to chemical degradation

j) Water vapor permeability of coating for mitigating corrosion

k) Ease of repair

l) Retention to its physical characteristics

m) Resistance to changes and deterioration during aboveground storage

Other factors considered are:

n) Accessibility to tank

o) Operating temperature of tank

p) Costs

q) Surface preparation requirements

r) Recoat interval

Since water vapor permeability of food-grade epoxy coating is much less than epoxy mortar and can be applied to a coating thickness of 400 µm (15.7 mils) dry film thickness (DFT) and considering other analysis from different angles, the engineering committee decided to use a food-grade epoxy system with a final DFT of 400 µm.2-3

Food-grade epoxy is a two-component solventless epoxy coating/lining technology formulated with a special grade resin, hardener, nontoxic pigment, and additives designed for permanent water contact and provides an effective, seamless waterproof layer. It is used for handling potable water in pharmaceuticals, food, biotechnology, and beverage processing, or for any application involving potable water.

Laboratory and field measurements also show the lining system is suitable for corrosion mitigation over a prolonged period of time and is cost effective. Performance criteria have been tested against normal and accelerated conditions. The observations made in the field applications have shown that the lining is protecting the tank surface against corrosion.

Procedure for Food-Grade Epoxy System

The existing coated epoxy mortar was totally removed by scraping, hammering, and chiseling. Further, as shown in Figure 3(a), the laying of Z angle on the whole floor in 1.5- by 0.7-m (4.9- by 2.3-ft) box type rectangles required replacing staging, angles, columns, and beams that were welded and installed (Figure 3[b]). To reduce tank weight, the concrete roof slab was replaced by a 10-mm (0.39-in) thick mild steel (MS) plate. After the necessary repair and replacement, a 400-µm food-grade epoxy coating was applied.

As the coating was completed, a 50-mm (2-in) thick M40 concrete, per IS 10262,4 was laid over the floor. After design calculation, a committee of experts recommended the M40 concrete balance the tank to offset replacement of the concrete roof slab. Further, a 10-mm thick MS plate was placed like tiles on the M40 concrete floor after applying a 400-µm food-grade epoxy on the bottom side of the MS plate. Additionally, after fixing the MS plate by welding, a food-grade epoxy coating of 400 µm was applied to the topside of the MS plate.

Food-Grade Epoxy System— Surface Preparation

The tank surface was prepared by dry abrasive (copper slag) cleaning per ISO 8501-1 Sa 2.5 (near white metal).5 Based on the condition of the tank, copper slag blasting was chosen instead of steel shot/grit to avoid pinholes and cracks during blasting, as the tank is more than 100 years old. The mill scale, rust, and foreign matter were removed completely. Finally, the surface was cleaned by using compressed air and solvent. The cleaned surface was compared with the photograph of the Sa 2.5 grade.

Food-Grade Epoxy System— Surface Profile

Food-grade epoxy coating and lining systems specify a surface roughness to ensure proper bonding of the coating/ lining to the metal surface. This is commonly referred to as an anchor pattern. If the metal surface is not sufficiently rough, the coating/lining may not adhere properly and will fail.

The anchor surface profile depth was kept at a minimum of 50 µm (2 mils). The surface profile was checked using a surface profile gauge or compared to a surface roughness comparator.

Food-Grade Epoxy System— Environmental Condition

The food-grade epoxy system was applied when relative humidity was below 85% and the substrate temperature was 3 °C (5 °F) above the dew point. Mixed food-grade epoxy material was applied when the ambient temperature was more than 10 °C (50 °F). An online heating system was used to keep the temperature of the mixed material between 30 to 40 °C (86 to 104 °F) for smooth spraying to build up a uniform film of coating.

Food-Grade Epoxy— Application

When applying coating materials to a metal surface, several factors should be considered, including the selection of a spray application method and proper spray technique that would help achieve continuous coverage at the correct thickness. Several articles describe different techniques that can be used to optimize film build when applying coating materials by two-component hot airless spray to the metal surface.6-8 The recommended distance, spray gun tip-to-metal surface, is 20.3 to 45.7 cm (8 to 18 in). Overlapping of the fan spray pattern compensates for relative “unevenness” across the fan width. An initial pass was made (e.g., left to right, not to exceed 0.9 m [3 ft]), then a second pass was made in the opposite direction, not to exceed 0.9 m, and overlapping the previous pass by ~50%. Two coats of food-grade epoxy were applied to achieve a desired thickness of 400 µm with an interval of four hours.

Post Applications

Food-Grade Epoxy System—Measuring of Dry Film Thickness9-11

Step 1: Instrument calibration

Step 2: Verification of gauge accuracy on certified coated standards or certified shims

Step 3: Base metal reading acquisition or gauge adjustment (using certified shims)

Step 4: Measurement of coating thickness at 400 µm

Food-Grade Epoxy System— Holiday Testing9,12

Holiday testing is one of the nondestructive test methods applied on protective coatings to detect unacceptable discontinuities, such as pinholes and voids in a coating/lining. If any pinholes are found, they are repaired.

Food-Grade Epoxy System— Adhesion Testing

9,13

The tensile pull-off test method for adhesion testing, as outlined in ASTM D4541,13 involves gluing a test dolly to the coated surface and then pulling the dolly by exerting a force perpendicular to the surface in an effort to remove the dolly with the coating from the substrate. The force at which this occurs, and the type of failure obtained, were recorded as a measure of the adhesion properties of the coating.

Food-Grade Epoxy System— Test Reports

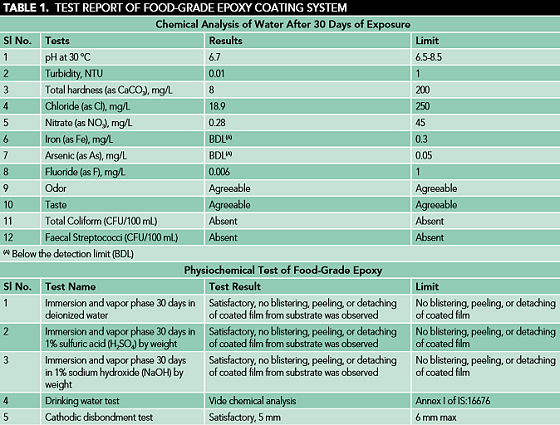

Table 1 shows the post installation testing data and some of the physiochemical properties of the epoxy.

Conclusions

Laboratory and field measurements show the potable water tank lining system is compatible for corrosion mitigation over a prolonged period of time and is cost-effective. Performance criteria were tested against normal and accelerated conditions.

The observations made in the field applications have shown that the lining is protecting the internal tank against corrosion and there are no signs of corrosion at this point. Moreover, as the coating system is chosen as food-grade epoxy, the supply of water from the tank is safe for human consumption over a prolonged period of time.

References

1 NACE SP0169-13, “Control of External Corrosion on Underground or Submerged Metallic Piping System” (Houston, TX: NACE International, 2009).

2 AWWA D103, “Factory-Coated Bolted Carbon Steel Tanks for Water Storage” (Denver, CO: AWWA, 2019).

3 AWWA C210, “Liquid-Epoxy Coatings and Linings for Steel Water Pipe and Fittings” (Denver, CO: AWWA, 2015).

4 IS 10262, “Concrete Mix Proportioning— Guidelines” (New Delhi, India: Bureau of Indian Standards, 2009).

5 ISO 8501-1:2007, “Preparation of steel substrates before application of paints and related products—Visual assessment of surface cleanliness—Part 1: Rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings” (Geneva, Switzerland: ISO, 2007).

6 J. Frakes, “Out in the Oil Field: Tank Coating,” CoatingsPro Magazine, October 01, 2014, http://www.coatingspromag.com/articles/steel-coatings/2014/10/out-in-the-oil-field-tank-coating.

7 AWWA D102-17, “Coating Steel Water- Storage Tanks” (Denver, CO: AWWA, 2017).

8 API 652, “Linings of Aboveground Petroleum Storage Tank Bottoms” (Washington, DC: API, 2014).

9 IS 16676: 2017, “Solventless liquid epoxy system for application on interior and exterior surfaces of steel water pipeline—Specification” (New Delhi, India: Bureau of Indian Standards, 2017).

10 NACE RP0105-05, “Liquid-Epoxy Coatings for External Repair, Rehabilitation, and Weld Joints on Buried Steel Pipelines” (Houston, TX: NACE, 2005).

11 SSPC-PA 2, “Procedure for Determining Conformance to Dry Coating Thickness Requirements” (Pittsburgh, PA: SSPC, 2018).

12 NACE SP0274-2011-SG, “High-Voltage Electrical Inspection of Pipeline Coatings” (Houston, TX: NACE, 2011).

13 ASTM D4541-17, “Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers” (West Conshohocken, PA: ASTM, 2017).