A newly released hybrid nanocoating system from Nanovere Technologies, LLC (Brighton, Michigan, USA) is utilizing three-dimensional (3-D) nano-structured polymers to produce high crosslink density and protect both industrial and commercial equipment.

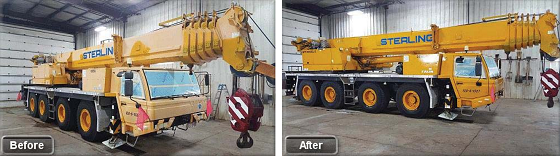

Known as Nano-Clear, the topcoat is applied over conventional paints and is designed to protect against corrosion; restore existing color and gloss; and provide strong resistance to ultraviolet (UV) degradation, extreme weathering, and chemical attack. Based on a proprietary chemical formula, the system also resists abrasions, chipping, marring, gouging, scratching, and more.

Known as Nano-Clear, the topcoat is applied over conventional paints and is designed to protect against corrosion; restore existing color and gloss; and provide strong resistance to ultraviolet (UV) degradation, extreme weathering, and chemical attack. Based on a proprietary chemical formula, the system also resists abrasions, chipping, marring, gouging, scratching, and more.

“Nano-Clear reduces maintenance frequency, recoating cycles, the chemical costs with mixing, repair, and cleaning, and the volume of coating material required,” says Thomas Choate, CEO of the technology company. “Thus, it reduces expenses.” Studies have found the product reduces the surface maintenance of paint by 50%, he adds.

The system was one of 10 winners at the 2019 MP Corrosion Innovation of the Year Awards, honored in March 2019 in Nashville, Tennessee, USA. Further technical details on the system, including case histories, are available at the awards web site.

Conventional Coating Limitations

According to the company, UV rays can cause conventional coatings to quickly degrade, leading to underlying corrosion. “Surface scratching exposes the steel to the environment, thereby causing corrosion,” Choate explains. “Chemical attack on conventional steel paints also cause underlying corrosion issues.”

The company notes that painted surfaces exposed to the environment are highly susceptible to damage from factors including water, humidity, salts, ice, heat, dirt, smog, oils, chemical attack, acid precipitation, and UV rays. This damage is of particular concern with assets, such as transoceanic ships, chemical tank cars, offshore oil rigs, heavy duty machinery, and fleet vehicles, since these assets are regularly exposed to harsh environments.

According to Choate, many of these industrial assets have historically utilized one- or two-component pigmented epoxy and polyurethane coatings for metal protection. However, while epoxies have strong adhesion to metal with good initial corrosion resistance and surface hardness, Choate says they can fall short in areas of long-term UV and chemical resistance due to poor crosslink density within the linear chain molecules.

Benefits of Nanocoatings

By contrast, the single component, humidity cured, polyurethane/polyurea hybrid nanocoating penetrates into the pores and voids of new or highly oxidized paint systems to form a hard, protective topcoat surface. As a solvent-based system with low volatile organic compound values of 150 g/L, the topcoat also features repellency properties for oil and dirt, water and ice, brake dust, algae, and other environmental and biological contaminants.

Choate says his company is the first group to utilize 3-D nanostructured polymers within an industrial coating system to achieve a high crosslink density. He explains that the system has been successfully tested by numerous third-party organizations, including a study in Israel where the product was tested in a salt spray chamber for up to 5,000 hours and then put through an in-field test for one full year at industrial plants that experience severe corrosion conditions.

The product uses conventional paint application techniques, including airless high-volume, low-pressure or low-volume, low-pressure spray equipment. As a single-component coating, it is humidity cured and requires only 2 to 3 mils (50.8 to 76.2 microns) to be applied.

It can be applied to coating systems, including two-component epoxies, two-component polyurethanes, powder coatings, polyesters, gelcoats, latexes, fiberglass, and anodized aluminum to prevent filiform corrosion. The system, which Choate says is impervious to water and oxygen, comes with a 10-year warranty.

“Nano-Clear can be easily incorporated into existing prevention and control activities, as it uses the same methods and techniques currently used by industries around the world,” Choate says.

Numerous Industry Applications

While the polymer-based system was first introduced to the industrial market in late 2014, Choate says his group continues to upgrade the technology each year. “Our latest nanocoating technology includes ice repellency and anti-barnacle prevention,” he explains.

According to the CEO, the system is engineered to exceed the functional specifications required in markets, such as industrial, marine, fleet, oil and gas, and aerospace.

Potential topcoat applications, along with their related equipment, may include rail tank cars, locomotives, fuel tanks, chemical storage tanks, earth-moving equipment, ocean vessels, fleet vehicles, painted building structures, light posts, utility enclosures, emergency response vehicles, oil and gas platforms, pipelines, shipping containers, military vehicles, mass transit vehicles, and more.

While the company’s coating systems are based on proprietary and newly synthesized materials and processes that require specific sequencing, Choate says further details are available upon request.

Source: Nanovere Technologies, LLC, www.nanocoatings.com. Contact Thomas Choate, CEO—e-mail: tom.choate@nanovere.com.