Developed as a U.S. Small Business Innovation Research (SBIR) project, the Corrosion and Coating Evaluation System (CorRES) aims to accelerate the screening, qualification, and implementation of new aircraft coatings, according to scientists at the Air Force Research Laboratory (AFRL) (Wright-Patterson Air Force Base, Ohio, USA).1

“By better understanding the corrosion performance of materials we put on an aircraft, we can help control corrosion costs and enable smart maintenance,” says Chad Hunter, the team lead for corrosion and erosion in the systems support division at the AFRL’s materials and manufacturing directorate. “Corrosion maintenance costs are more than $5 billion a year for the Air Force, so if we can better understand a material from the start, we can enable smart maintenance and ultimately reduce costs throughout the life cycle.”

According to the Air Force, aircraft coatings are the first line of defense when it comes to mitigating the structural corrosion of an air platform. As new coatings are developed, particularly those containing non-chrome primers, AFRL researchers say material qualification tests are essential.

Use of Sensor Panels

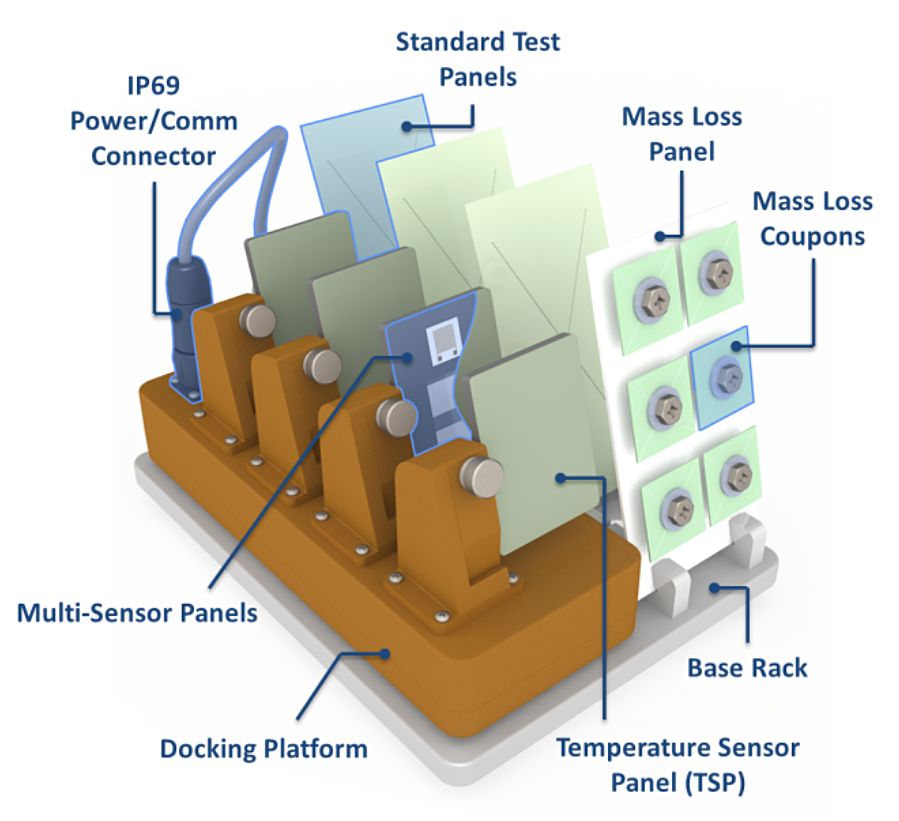

To address this challenge, the CorRES system measures the ability of coatings to protect aircraft structures using sensor panels that perform electrochemical measurements during corrosion testing.

Unlike conventional coating tests that rely on an expert’s visual evaluation of a test panel at the end of a test cycle, CorRES records corrosion rate data throughout a test and transmits the data over a wired RS-485 interface cable to a base station for evaluation.

This enables researchers to know not only if a coating fails, but exactly when this occurs during a test. Each system includes continuous environmental measurements of temperature and humidity, and a module for evaluating the ability of coatings to protect alloys from stress corrosion fatigue is also part of the system. Data collection and storage are fully automated so that environmental measurements, along with corrosion rate and crack velocity, are continuously measured throughout a test.

“Legacy systems do not produce time-based, quantitative measurements inside of the test chamber, but rather, these are taken after a panel is removed,” Hunter explains. “There’s a lot of variability in corrosion tests, and CorRES allows us to monitor this variability and provides quantitative data that help us better understand a coating’s performance in the lab so we can project how it will perform in the operational environment.”

The system is designed for both accelerated chamber use in the laboratory and at outdoor sites in the field, and it can be operated autonomously or by using a connected laptop computer.

Interdigitated Electrodes

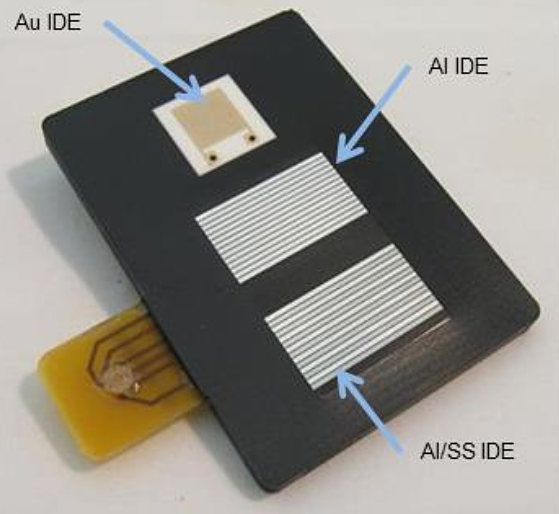

Each multi-sensor panel includes a gold interdigitated electrode, an AA7075-T6 (UNS A97075) aluminum alloy electrode, and an electrode comprised of the AA7075-T6 aluminum alloy and Type 316L (UNS S31603) stainless steel (SS) in a single package.

Each multi-sensor panel includes a gold interdigitated electrode, an AA7075-T6 (UNS A97075) aluminum alloy electrode, and an electrode comprised of the AA7075-T6 aluminum alloy and Type 316L (UNS S31603) stainless steel (SS) in a single package.

The specialized test panels included with the system package—prepared, painted, and tested like traditional panels—are used to measure the ability of a coating to protect a given substrate from the environment as well as inhibit corrosion at a defect. Barrier properties of the intact coating are measured, as well as the corrosion rate of the engineered alloy or dissimilar metal coupling of interest at a defect (galvanic corrosion).

“[Conventional] tests focus on aesthetic performance and do not provide data of localized corrosion processes that represent the greatest risk to aircraft structures,” Luna says in explaining its technology.

More Comprehensive Data

According to the Air Force, this system provides a more comprehensive set of data because the sensing elements can measure free corrosion potential via the voltage difference between the immersed metal and the reference electrode, as well as galvanic corrosion, coating barrier properties, and the effects of the environment on coating materials—all in a single testing platform.

“With this system, we are able to get some granularity on performance,” Hunter explains. “For example, you can test 20 primers, and they all may pass, but the pass is with a different degree of success. This will help us to determine which performed the best based on sensing data. We can pinpoint when change happens.”

Underperforming coatings can be eliminated from screenings earlier in the testing process, thus streamlining qualification efforts and reducing the time and costs associated with coating tests for the Air Force.

“Part of our mission at AFRL is to develop new technologies to address technical questions and issues in the field,” Hunter says. “Multi-sensor panels and systems like CorRES provide us with useful information that can reduce costs as we develop next-generation materials for the warfighter.”

The Air Force says the platform is also being tested and used by industry, including a leading U.S. aircraft manufacturer, alloy producer, coatings raw material manufacturer, and the U.K. government’s National Physical Laboratory (Teddington, United Kingdom).

Sources: U.S. Defense Video Imagery Distribution System, www.dvidshub.net; Luna Innovations, www.lunainc.com; and SBIR, www.sbir.gov.

Reference

1 “New Corrosion Evaluation System Makes 'Sense' for Air Force,” Defense Visual Information Distribution Service News, March 20, 2018, https://www.dvidshub.net/news/269990/new-corrosion-evaluation-system-makes-sense-air-force (April 10, 2018).