Phosphorus has long been recognized as the controlling factor in plant and algae growth for many lakes and streams. A minor increase in phosphorous can fuel substantial increases in both aquatic plant and algae growth, which can have severe impacts on a community. Phosphorous can originate from municipal and industrial facilities that discharge water, as well as runoff water from agricultural areas that makes its way into local water sources. Restrictive phosphorus discharge limits are being enacted or proposed in many areas of the United States where the receiving water streams are particularly sensitive to changes in phosphorus levels.

For example, the Wisconsin State Department of Natural Resources (DNR) made the determination to reduce allowable phosphorus limits to 0.075 ppm (75 ppb) and as low as 0.04 ppm for facilities that discharge to more stressed waterways. When a Wisconsin ethanol producer using a traditional phosphorus-based cooling water treatment attempted to renew its National Pollutant Discharge Elimination System (NPDES) discharge permit, it was informed that it would be required to meet the new 0.075 ppm phosphorus limit.

The use of phosphorus-bearing compounds in industrial cooling and boiler water treatment programs has been commonplace since phosphorus replaced chromate in the early 1970s. Typical alkaline all-organic cooling water programs can have phosphorus levels from 0.3 to 2.5 ppm while stabilized phosphate programs can have phosphorus levels as high as 6.0 to 7.0 ppm. With the tightening restrictions now surrounding phosphorus treatments, other corrosion inhibitor options were not a viable recourse for this Wisconsin ethanol producer as most of the alternative programs available are primarily metal based and utilize metals such as zinc or molybdenum, which are also being closely regulated in terms of acceptable discharge levels.

Without an effective corrosion and deposit (scale) control program in place, the plant’s cooling system could be compromised in a relatively short period of time. The plant could experience significantly higher operating costs as well as product loss due to overheating in the fermentation and distillation areas as a consequence of reduced heat transfer efficiency from scale deposits forming on the heat exchanger tubes. With few options available to it, the ethanol producer turned to U.S. Water for help.

In anticipation of the tightening restrictions on phosphorus and many of the metal-bearing compounds currently used in industrial cooling treatment, U.S. Water recently developed a “green” corrosion and scale inhibition technology, PhosZero† with E-FeX† Technology. This chemical treatment technology contains no phosphorus while providing corrosion and scale control performance at least equivalent to traditional cooling water treatment. Corrosion protection is achieved through the development of a protective iron oxide layer.

When presented with this new technology, the plant agreed to trial this new product at its facility. The plant employs induced draft counter flow cooling towers, a four-cell distillation tower, and a three-cell fermentation tower. The fermentation tower, comprised of mild steel, copper, and Type 304 (UNS S30400) stainless steel (SS) metallurgies, runs for six months, from May through October, at an estimated 18,000 gal/min (68,130 L/min) recirculation rate. The distillation tower runs year round at an estimated 12,600 gal/min (47,691 L/min) recirculation rate and is comprised of mild steel and Type 304 SS. A treatment program with the corrosion and scale inhibitor technology was implemented at the plant.

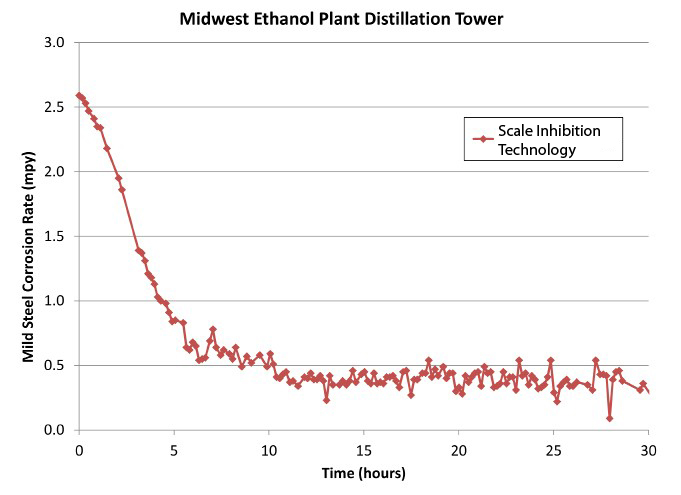

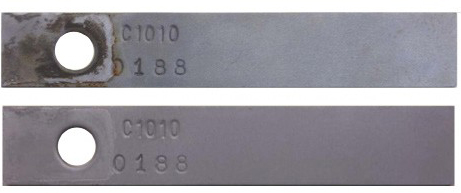

In order to ensure the new technology would protect the cooling system from corrosion better than the existing technology, corrosion rates were carefully monitored using corrators (see Figure 1) and corrosion coupons. Additionally, an online monitoring solution was installed in order to verify performance and track the system’s progress 24 hours a day, seven days a week.

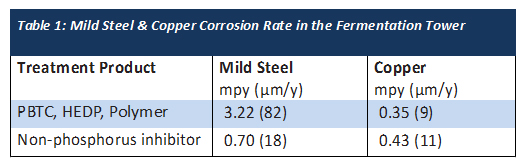

Results of the non-phosphorus treatment program were excellent (see Figures 2 and 3, and Table 1). After 51 days of exposure, the mild steel showed a corrosion rate of 0.702 mpy (18 µm/y) while the copper showed a corrosion rate of 0.434 mpy (11 µm/y) with no azole feed (Figures 4

and 5). Analysis of the water chemistry during the trial, as well as heat exchanger performance monitoring, showed no indication of scale formation even though the cooling water’s average Langelier Saturation index (LSI)—an indicator of the degree of calcium carbonate (CaCo3) saturation—during the trial was 2.5, an indication of significant scale potential.

Not only was the plant able to address its original goal of meeting effluent phosphorus discharge limits, but use of the green non-phosphorus water treatment provided better corrosion protection than the plant had experienced with its existing conventional program.

Source: U.S. Water, uswaterservices.com.

†Trade name.