The coating and corrosion conditions of one of the gas networks in the urban areas of Iran was such that the only solution was to replace the pipeline with a new pipeline. Due to the crowdedness of the city and the existence of some underground facilities such as telecommunications cables, it was not possible to pull out and remove the entire old network from the ground.

By using a combination of metal and polyethylene pipes in the new network and increasing the electrical resistance of the interference circuit, the problem of cathodic protection (CP) interference in the new network was solved.

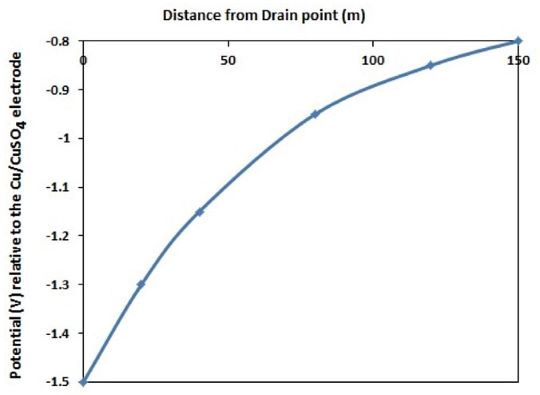

Cathodic protection (CP) current increases as pipeline coating quality decreases. Also, with a decrease in the quality of the pipeline coating, CP potential is not properly distributed along the pipeline route. The amount of CP potential reduction per kilometer of the pipeline is called CP potential attenuation value (α).

Table 1, located near the bottom of this article, shows that as coating quality decreases and α increases, new CP systems must be added to the pipeline to establish proper CP potential distribution. In other words, the distance between drain points decreases.1 Based on the experiences of Iran Gas Company, when the value of α exceeds 0.4, the program for repairing or replacing the pipeline coating should be on the agenda.

In urban areas, especially downtown, crowds, high traffic, and the presence of underground facilities such as telecommunication cables made replacing the pipeline with a new pipeline, or replacing the old pipeline’s coating, a problem. In the next section, field experiences to solve these problems are presented.

Field Tests and Results

The length of the old gas network was about 20 km and included 2-, 4-, and 6-in pipes covered with PVC tape. Due to the low resistance of the soil (480 Ω·cm), the pipes were subject to corrosive conditions. The normal current of its CP at the beginning of its work—that is, about 40 years ago—was 12 amps, and after 40 years, it increased to 58 amps.

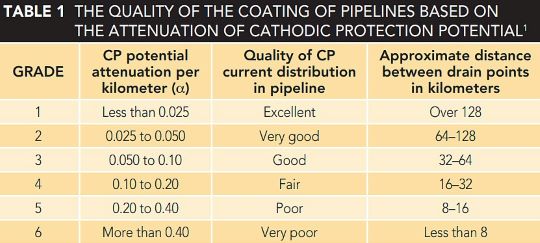

The attenuation of the CP potential was very high with increasing distance from the drain point. The α value was greater than 4, and, as Figure 1 shows, at a distance of 150 meters from drain point. As a result, the CP potential was attenuated from −1.5 to −0.80 volts compared to the Cu/CuSO4 electrode. In this case, some parts of the network were under protection.

Because of the many problems caused by changing the pipeline coating or replacing it with a new pipeline in crowded urban areas, it was decided to add three new CP stations in order to improve the CP potential, thereby reducing the distance of the drain points from each other.

The three aforementioned stations were injecting a total of 31 amps of current into the pipeline, but they could not bring the entire network to the proper CP potential, and about 40% of the network was still underprotected.

However, in order to prevent problems in the central part of the city, which has high traffic and congestion, improving the CP potential of the pipeline and avoiding extensive excavation operations to repair the coating or replace the new pipeline were prioritized.

Therefore, one of the options was to bring the areas below the protection level to the protection level locally by using mixed metal oxide wire anodes. However, the low soil resistivity and the high current of CP raised the possibility that the pipeline may have suffered serious corrosion damage. Thus, before implementing local CP, the condition of the pipeline in terms of corrosion should be investigated in several different places through local excavation.

According to field observations in the excavated areas, the pipeline coating had completely lost its adhesion to the pipeline (i.e., delamination) and had become brittle. Also, the pipeline was badly corroded under the PVC tape.

Figure 2, at the top of this page, shows an example of severe corrosion under the PVC tape. Local CP on the worn and severely corroded pipeline was not technically and economically justifiable. Therefore, replacing the old pipeline with a new pipeline coated with coal tar was on the agenda.

In terms of CP, the old pipeline would cause CP interference with the new pipeline.2–5 The excavation and removal of the old pipeline would take months to complete and would cause gas distribution in the city center to stop for months, which would create acute problems for city management.

Therefore, in the presence of the old pipeline, the new pipeline was implemented. In many places, the new pipeline was parallel with or crossed the old pipeline. In three places, the new pipeline intersected with the old one, and the possibility of CP interference was high in these places.

In each of these places, 500 meters of polyethylene pipes were used, with 250 meters from each side of the intersection, and the two sides of the pipeline at the intersection were connected to each other by using an electric cable.

After completing the implementation of the new pipeline, gas branches were connected to it and disconnected from the old pipeline. Fom there, the other CP interference caused by the existence of the old pipeline was eliminated.

Two suggestions were made to resolve the CP interference:

- Using the old pipeline as a near anode bed

- Increasing the electrical resistance of the interference circuit to eliminate the current interference.2–5

Although the first proposal seems good, it could cause problems for the CP system of the new pipeline in the short term. In this case, after a short period of time, the electrical connection of different parts of the old pipeline was disconnected due to corrosion, and as a result the CP was completely lost while the old pipeline was used as an anode bed.

Also, in some places there was a possibility of an unwanted short-circuit connection between the new network and the old network.

Finally, carrying out a complete excavation to remove the old pipeline from the soil would again create many problems for the people in the crowded area of the city. Therefore, the first proposal was not acceptable, and the second proposal was implemented.

In order to increase the resistance of the interference circuit, approximately 70% of the old pipeline was removed, but removing the remaining 30% would have created severe problems to urban areas or posed serious risks to underground facilities such as telephone cables.

Therefore, excavation was done locally in different places, and the remaining old pipeline was cut into nine parts. Then, seven CP stations of the old pipeline were used for the new pipeline. The potential of drain points of these seven stations was set at a potential of −1.2 V relative to a copper/copper sulfate electrode (CSE).

The total current of all stations was 15 amps, and the range of CP potential changes in the entire network was between −0.9 V and −1.20 V compared to the CSE. Therefore, in this case, the CP interference caused by the old network was minor and could be ignored. Also, with the corrosion and rotting of the old network inside the soil, the situation of CP potential distribution would be better.

Conclusion

The operation of replacing a pipeline or removing the CP interference should be done considering the limitations of crowded urban areas. In other words, solutions should be chosen that will minimize the amount of problems caused by the pipeline replacement operation or the elimination of flow interference for people.

As seen in the process of the project, the solutions chosen at different stages were such that they would create the least problems for people living in urban areas.

Acknowledgments

The cooperation of the Khuzestan gas distribution company is appreciated.

References

1 Iranian Petroleum Standard (IPS), IPS-ITP-820, p. 34.

2 A. Saatchi, A. Aghajani, “Interference Problems in Cathodic Protection of Complex Installation,” MP 44, 12 (2005).

3 A. Aghajani, A. Saatchi, “Correcting Nonuniform Potential distribution and Interference Problems in the Cathodic Protection System of a Gas Compressor Station,” MP 53, 4 (2014).

4 A. Aghajani, A. Saatchi, M. Shirani, “Cathodic Protection Problems for Gas Pipelines South of Isfahan, Iran,” MP 55, 1 (2016).

5 A. Aghajani, “Cathodic Protection Problem for a Gas Pipeline near a Compressor Station,” MP 56, 1 (2017).

Editor’s note: This article first appeared in the August 20234 print issue of Materials Performance (MP) Magazine. Reprinted with permission.