Safety first. Followed by cost savings and environmental protection.

Those were the priorities when the aptly named Deepwater Corrosion Services team set out to retrofit three of the deepest oil and gas platforms in the world off the coast of Goleta, California, USA.

“In terms of scope, it was the single largest offshore ICCP [impressed current cathodic protection] retrofit that has ever been done in one retrofit campaign,” says Sami Abu-Zahra, PE, senior corrosion engineer with Deepwater Corrosion, which handled the retrofit to equip the platforms for 25 more years of service.

Abu-Zahra teamed with his Deepwater Corrosion colleagues Mathew L. Taylor, Ph.D., and Omar Rosas-Camacho, Ph.D., to write the AMPP paper “Life Extension of Offshore Field in the Santa Barbara Channel 1: Simultaneous ICCP Retrofit of Three Jacket Platforms.” The paper, which Abu-Zahra presented at the AMPP Annual Conference + Expo in 2023 in Denver, Colorado, USA, is one of three papers about the project that the trio wrote.

About the Santa Ynez Unit

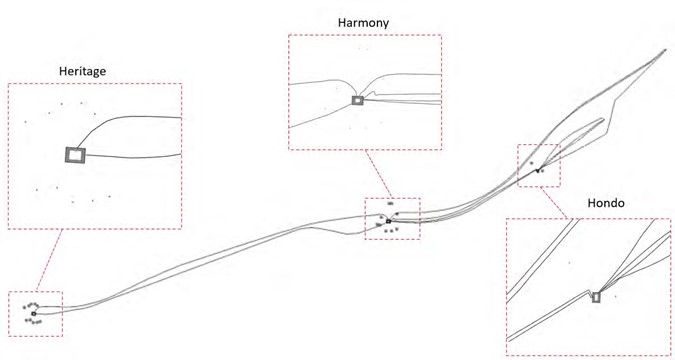

The Santa Ynez Unit produces crude oil and natural gas from three platforms—Harmony, Heritage, and Hondo. The three platforms are located off the California coast in the Santa Barbara Channel.

According to ExxonMobil, the oil and gas are transported through a subsea pipeline and treated at the Las Flores Canyon Oil and Gas Plant and the Pacific Offshore Pipeline Company (POPCO) Gas Plant, approximately 20 mi (32 km) west of Santa Barbara, California. The onshore facilities separate oil, propane, butane, sulfur products, and fuel-quality gas.

Harmony, Heritage, and Hondo were installed between 1979 and 1989 in water depths between 259 m to 365 m (about 850 ft to 1,200 ft).

These platforms, located 19 km (11.8 mi) west of Goleta, were previously retrofitted with ICCP sleds that were in decline, requiring additional ICCP anode output.

“Operators frequently want to extend a platform well beyond the original design life due to increasingly efficient methods of extraction and re-drilling,” the authors explain in their paper.

Deeper platforms, they continue, require higher-output ICCP systems due to larger bare steel surface areas immersed in seawater. Deeper structures tend to have 30 to 36 conductor bays, compared with the typical eight to 16 bays found in the Gulf of Mexico.

About the Retrofit

Cathodic protection (CP) system retrofits, either upgrade or replacement, are typically required to prevent subsea corrosion beyond the initial design life of offshore assets, the engineers write.

“Harmony is one of the tallest platforms in the world,” Abu-Zahra says. “So, the steel structure below the waterline is extremely large. The amount of steel surface area is immense. Most fixed jackets in the Gulf of Mexico, for example, are around 300 ft (0.09 km) deep, so this is four times deeper.”

Cost and environmental impact were reduced by re-utilizing existing equipment, minimizing remotely operated vehicle (ROV) time, and avoiding extensive structural modifications, the authors explain in their paper, in which they describe the equipment and installation methods used to provide a total of 21,000 amperes of current output capacity.

Abu-Zahra, a native of Canada, is a licensed professional engineer in Texas with experience around the world including in Canada, the United Kingdom, and in Houston, Texas, USA, where he is based with Deepwater Corrosion. He has been to more than 50 countries and have done work in every major body of water in the world.

“The first focus was safety,” he says. “Every design choice was evaluated with respect to risk. And it wasn’t about the cheapest solution, it was about the solution with the least risk. To send someone to those depths is extremely dangerous, and it’s also very expensive. So, using the ROV is a much more cost-effective solution. It’s also a lot safer.”

Even using robots, the engineers sought to minimize the amount of time they were in the field for environmental reasons.

“The longer you have a boat operating, the more pollution you will have just by energy usage,” he says. “You want to make the installation process as quick as possible and do as much preparation ahead of time as is feasible.”

Design Challenges

Deepwater Corrosion, founded in 1986, calls itself a full-service offshore corrosion control company supplying the energy industry with expertise in CP and corrosion engineering. It develops more efficient systems to protect, monitor, and extend the productive lives of assets.

The field, the authors write, comprised five coated subsea pipelines, one steel catenary riser to fixed subsea pipeline connected to the platform, and three abandoned pipelines that are no longer in use connected to Hondo.

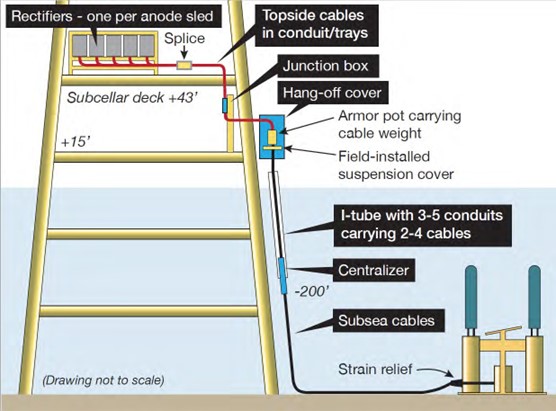

The designers and client chose a free catenary approach as the most cost-effective method of connecting the topside components to the subsea anode sleds.

“The cable construction allows for it to be freely suspended from the topside flange, exits the I-tube at -61 m (-200 ft) mean seawater level, then suspended in a catenary until the touchdown point, the remaining cable length was routed along the seafloor and terminated at the anode sled,” they write.

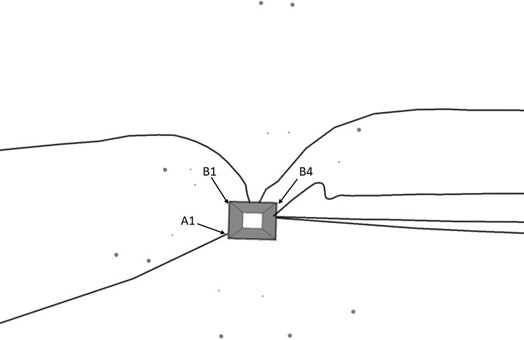

“The ICCP system for each structure comprises an array of remote seabed mounted anode sleds some distance from the jackets as illustrated in Figure 2. As part of the scope, optimized placement of the ICCP anode sleds were identified to reduce risk to the pipelines and improve performance of the jacket structure.”

The retrofit ICCP system was designed to:

- Provide supplementary CP to the submerged areas of the platforms that have become depolarized due to anode loss.

- Extend the effective design life of the CP system by 25 years while maintaining adequate levels of CP to the entire submerged structures.

- Provide additional protection onto the exterior surfaces of the platform and minimize the additional retrofit equipment needed to address the protection of the interior members of the jackets.

- Minimize the risk to foreign structures, such as connected pipelines due to the application of the retrofit ICCP system.

To simplify and reduce the overall cost of the installation, the requirements included:

- Safe installation without injury to personnel

- Large operational weather window (the weather cooperated nicely, Abu-Zahra reports)

- Performing all connections to anode sled while onshore or at port

- Modular system with interchangeable components to minimize number of required types of spares

“We were able to successfully do this because we took a modular approach to how this was designed,” Abu-Zahra says. “So, rather than designing a perfectly customized solution for each of the three platforms, each of multiple locations per platform, we took a modular approach to the overall system such that we just had to vary some of the parameters such as the cable length. We were able to achieve the end goal with things that look very similar in the end, and this made it easier to fabricate and easier to manage.”

“After a full inspection, the system was commissioned, operationally tested, and energized to full output,” the engineers write in their paper. “The system was left to re-polarize the platforms and monitored after a year of operation, which demonstrated an immediate average shift of 118 mV and further average shift of 58 mV after a year operation across the platform. During this monitoring period, the system can be re-adjusted based on the overall system output and fine-tuned by adjustment of the individual anode placements.”

The project took about 22 months from conception to installation.

“One of the reasons that I very much enjoy working for Deepwater Corrosion Services is the ability to see a project through from the beginning until the end,” Abu-Zahra says. “It’s very rewarding to see something that started off as a napkin design created, manufactured, installed, and then functioning in the field.”

Editor’s note: This article first appeared in the April 2024 print issue of Materials Performance (MP) Magazine. Reprinted with permission.