The author was contracted to perform a multiphase corrosion control project on a new pipeline in southeast Texas. The project encompassed the design of cathodic protection (CP) and induced alternating current (AC) mitigation systems, with subsequent installation, commissioning, and post-construction survey work.

Commissioning activities included the CP and AC mitigation systems, with the survey work to include close-interval potential and direct current voltage gradient surveys. Specifications provided to complete the commissioning and survey work were limited to broad stroke task expectations and not order of operations.

An examination of related literature for guidance on simultaneous performance of commissioning and survey work revealed a dearth of information associated with this combined scope of work. Singular lanes of information are available to complete each task—for example, what testing to perform on a new alternating current (AC) mitigation system and each grouped task and how to complete both close interval potential (CIS) and DC voltage gradient (DCVG) surveys.

The overlap of commissioning, testing, and survey execution needs, as well as the divergence in needs between categories, for the entire corrosion control system required mapping the process and needs for each commissioning and each survey type.

This created a process flow in which the result of a testing or survey event provided the base of knowledge for the next testing or survey event. Concurrent testing/surveying was performed when possible, although given the hierarchy of needs, this was not always possible.

The rate at which new pipelines are being built and installed is not slowing, and efficiency in corrosion control testing and surveying will become paramount as these new systems are installed and come online.

Increasing Oil Production and Pipeline Construction

In 2018, the United States was the largest crude oil producer in the world, with 40.5% of all crude oil being produced in Texas.1 Although 2020 proved to be a challenging year for all, Texas still led the country in production and was slated to exceed pre-pandemic levels in December 2021.2

For the last century, production of petroleum products has been increasing as a general trend, with 2018 being a peak performing year. From 2013 to 2018, production of oil in Texas increased by 657,927,277 barrels to a total of 1,585,838,357 barrels.3

Transmission of liquid petroleum products to refining or export locations is a critical step for producers and consumers of end products. This step is also the greatest bottleneck for satisfying demand of raw material processing, a critical point in the supply chain that has become a global focus in 2021.

While production of oil has increased globally, there has not been a similar increase in the ability to transport product. Worldwide, there was only a 13% increase in the number of onshore pipelines installed in 2018.4 The state of Texas has the largest network of existing pipelines in the United States, with 483,571 mi (778,232.09 km).

According to the Texas Railroad Commission (RRC),5 the state issued 69 new pipeline construction permits through November 1, 2021—the majority of which are metallic.6 In general, these new pipelines will bring the product from the production point to refineries and export locations, many of which are hundreds of miles away. Globally, about U.S. $1.07 trillion in pipelines are currently in development.7

New Pipelines and Corrosion Prevention

In the United States, new metallic pipelines are regulated by Part 192, “Transportation of Natural and other Gas by Pipeline: Minimum Federal Safety Standards” in Title 49 of the Code of Federal Regulations. Subpart I, “Requirements for Corrosion Control,” details the minimum requirements for corrosion control and prevention for all pipelines installed after August 1, 1971.

According to Subsection 192.455, new pipelines must have an external protective coating and a working cathodic protection (CP) system one year after construction of the pipeline has been completed. The federal regulations also dictate monitoring (subsection 192.465), stray current program management (subsection 192.473), and direct assessment (subsection 192.490), the records of which must be kept for a minimum of five years.8

The purpose of this testing and continued monitoring is to establish the working condition of the corrosion protection system, which takes into account corrosion that may occur from other means (stray current management, high potential areas), and that the system continues to operate at a level that prevents corrosion of the pipeline.

As the pace of new pipeline construction increases, there is a subsequent increase in demand for corrosion protection services. Satisfying the increasing demand for services requires not only an increase in production of services but an increase in efficiency of delivery of services. This includes all aspects from design of the corrosion protection system to installation, testing, and future monitoring.

Case Study: Multi-Stage Commissioning and Concurrent Survey Work

For this case study, a new pipeline was installed in South Texas, and a full suite of corrosion services was requested. The project began with the CP and AC mitigation designs and followed with the construction and installation of the systems themselves.

Post-installation corrosion work was then contracted as line items to be completed at the behest of the contractor. Initially, these items included the following: CP commissioning, AC mitigation commissioning, native CIS, DCVG survey, and an interrupted CIS.

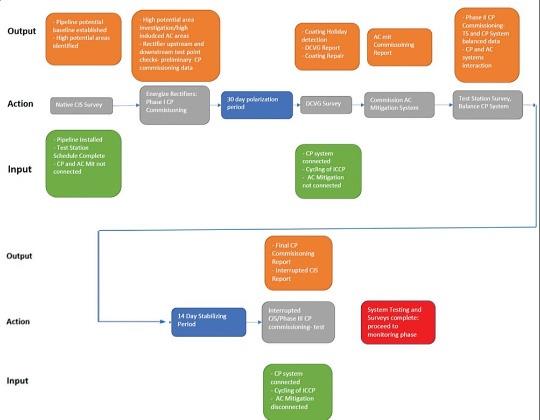

Each scope item has its own set of needs and outcomes as demonstrated below in Figure 1 and its own approved process as dictated by AMPP (NACE). Completing the items would have to be carefully executed. The question, then, became how to execute all of the scope items and in what order.

Each of the scope items has a clear procedure and set of expectations for typical execution, as dictated by AMPP (NACE) standards, although there is no specified timeline of execution. Execution of each item has specific requirements that may overlap with other closely related items; for instance, when survey work for both CIS and DCVG is requested.

Best management procedures for individual scope items are commonly available and provide clear instruction for execution, but between the differing categories of commissioning, testing, and survey work, there is limited information.

Experimental Procedure

The procedure for this case study centers on the establishment of a hierarchy of scope items and their placement into a timeline that can then be executed. The hierarchy was established by evaluating the inputs and outputs of each scope item and evaluating which outputs of one item are an input to another process item. This did create intermediary steps, where it was realized the necessary inputs for the process item did not exist in any other inputs or outputs.

It should also be noted that the hierarchy was evaluated to explicitly limit any part of the corrosion system being inoperable; as such, secondary procedures were established. For example, in executing the interrupted CIS, the AC mitigation systems should be disconnected.

Limiting downtime of the AC mitigation system was a priority given there were other operable pipelines within the area, thus the system was disconnected and reconnected surrounding the survey crew. While this increased the complexity of the overall procedure, the health of the corrosion system was maintained. Ultimately, what began as a step-by-step guide to cross scope items off a list became a process guide to increase the corrosion systems functionality.

An important piece of the hierarchy was to be able to utilize data being collected to produce reports that could be distributed among the stakeholders in a timely and relevant way, hence the deliverables section of the hierarchy process. As each scope item was performed, building blocks of the overall corrosion system were being established.

With each piece of information, the system was able to be aligned in its ultimate functioning. This creates intermediary steps (adjusting rectifiers after polarization for example); however, the process of installing a new pipeline may occur across various spreads, leading to differing corrosion needs to be rectified into one system.

Results

The result of the scope evaluation is shown in Figure 1, which showcases the inputs, outputs, deliverables, and action items for the commissioning, testing, and survey work required. The ability to utilize data as the commissioning, testing, and survey work was completed meant that the corrosion system’s health could be evaluated throughout the process.

Creating layers of information on the corrosion system enables future operators to understand the system more fully and manage the corrosion protection system. Recognizing the interplay of the corrosion activities creates more meaning in each activity beyond a scope item to complete for operation.

Discussion

The process map created shows the interplay between multiple corrosion disciplines and the effect that each has on the other. While care was taken to prevent double work or multiple trips, the simple fact remains that the AC mitigation systems are going to be connected and disconnected multiple times.

Mapping the process prior to being in the field enabled each team to have a better understanding of the expectations associated with their portion of the project. The visual nature of the process map also brings awareness of the time associated with each portion and the total process time to bring the pipeline into the monitoring phase.

Performing this hierarchical technique for pipeline corrosion commissioning and survey does increase the repeated need for access to many groups of corrosion professionals, which may not be ideal in all situations. As one can see in this case study, there is survey work performed at both the beginning and the end of the entire system’s process.

Similarly, the need for technicians and engineers fluent in both CP and AC knowledge areas can create a limited pool of professionals from which to draw. In this case, sourcing the field personnel and survey groups required schedule and personnel management that may not be feasible in all situations. The fluid nature of the hierarchical process and delineation of needs by project does allow for movement of processes as is seen fit.

Treating the testing and commissioning phase of the project as one true corrosion system and not as singularities of CP and AC mitigation creates a more holistic process with more evaluation techniques being done throughout the process.

When all the testing processes are layered on top of each other, there is a greater chance that early warning signs can be caught, and a better operating system is created. Future work associated with this process mapping would be to determine if greater efficiency is reached in getting the pipeline operational, and if creating the process map creates a longer-lasting and more efficient long-term corrosion system.

Conclusions

The hierarchy and process guide that was created is in no way a singularity; instead, this has been chosen through collaborative exchange between multiple stakeholders and can be altered in the future depending on other individual or group needs.

Operator requests, process limitations, and changes in timeline are all factors that must be considered in future cases. The use of the input and output generator process can thus be adapted and utilized by general contractors, corrosion firms, and pipeline operators to collaboratively produce pipelines that are not only completed in a timely manner but turned over to operations groups in good working condition.

A common theme that came up during the initial hierarchy discussions is the acknowledgement that each scope item is part of a larger process of turnover and is thus not the simple line item that one may expect. For example, one is not merely performing the DCVG survey; this is feeding into the CP commissioning as the survey has identified areas that may pose a threat to system integrity and potential disruption of the corrosion control system.

In this way, while each item of the hierarchy is performed in a linear fashion, the actual system is a positive feedback loop of information and data collection, building on the process preceding it to create a picture of the corrosion ecosystem and the management of it as a whole.

Editor’s note: This article first appeared in the July 2023 print issue of Materials Performance (MP) Magazine. Reprinted with permission.