The third and final deadline for underground storage tank (UST) owners and operators to meet new federal requirements from the U.S. Environmental Protection Agency (EPA) (Washington, DC, USA) for spill, overfill, and corrosion protection is October 13, 2018. By that date, UST managers must fully comply with the agency’s latest UST regulations, which were effective on October 13, 2015. The final deadline of the three-tiered process comes after two prior due dates of October 13, 2015, and April 11, 2016.1

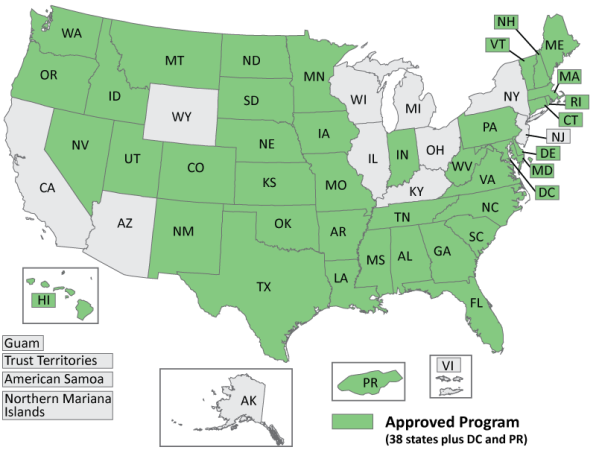

The exact steps UST owners and operators must take—and additionally, who they must report to in 2018 as part of the compliance process—vary based on location. In general, the EPA says that because of the size and diversity of UST assets, it recognizes that state and local authorities are in the best position to oversee because they are closer to each individual situation and can set appropriate priorities. Once state legislatures enact statutes, and state agencies develop UST regulations in accordance with EPA requirements and put other components of a program in place, states may apply for formal approval, and the EPA must respond within 180 days. Each state plan is approved if it meets a range of criteria, which include the establishment of standards for eight performance criteria that are no less stringent than federal rules; provisions for adequate enforcement; and regulation of at least the same USTs that are regulated under federal standards. Once approved, states have the lead role in UST program enforcement, and UST owners and operators in states with an approved program do not have to deal with two sets of statutes and regulations (state and federal) that may be conflicting. In states without an approved program, EPA works in tandem with state officials in coordinating UST compliance.

As of September 2017, 38 states, the District of Columbia, and the Commonwealth of Puerto Rico had approved state programs. Those states must reapply to retain their approved program status by October 13, 2018. As part of that application process, the state must demonstrate “adequate enforcement” procedures and show how it enforces the technical regulations to any asset owner or operator not in compliance. In those states, UST owners and operators work with state authorities to show compliance for their asset(s). In states and U.S. territories without program approval, owners and operators must work with both state and federal authorities.

In both cases, new requirements that owners and operators must comply with by October 13, 2018 include site assessment records for groundwater and vapor monitoring, along with enhanced operator training. UST owners and operators must also conduct the first test or inspection on areas that include spill prevention equipment, overfill prevention equipment, containment sump testing for sumps used for piping interstitial monitoring, release detection equipment, and walkthrough inspections. Further details on these subject areas and others pertaining to the new UST regulations can be found at the EPA web site, www.epa.gov/ust.

UST Regulatory Background

In the United States, according to the EPA, petroleum or hazardous substances are stored in ~566,000 USTs. These USTs are located at hundreds of thousands of facilities across America. Contamination of groundwater, the drinking water source for almost half of all Americans, is the greatest potential threat from leaking USTs, which are one of the leading sources of groundwater contamination.2 U.S. UST regulations require owners and operators to design, construct, and properly install UST systems in accordance with industry codes and standards, and according to manufacturer’s instructions. UST owners and operators must follow correct filling practices and protect their USTs from spills, overfills, and corrosion. Additionally, owners and operators must report the existence of new UST systems, suspected releases, UST system closures, and keep records of operation and maintenance.

As part of the 2015 revision, all USTs installed after December 22, 1988 must meet one of the following performance standards for corrosion protection:3

• Tanks and piping are completely made of noncorrodible material, such as fiberglass-reinforced plastic.

• Tanks and piping made of steel have a corrosion-resistant coating and cathodic protection (CP).

• Tanks made of steel are clad with a thick layer of noncorrodible material (this option does not apply to piping).

• Tanks and piping can be installed without additional corrosion protection measures provided that a corrosion expert has determined that the site is not corrosive enough to cause the equipment to have a release due to corrosion during its operating life, and owners or operators must maintain records that demonstrate compliance with this requirement.

• Tanks and piping construction and corrosion protection are determined by the implementing agency to be designed to prevent the release or threatened release of any stored regulated substance in a manner that is no less protective of human health and the environment than the options listed above.

UST systems installed before December 22, 1988 also must be protected from corrosion. These USTs must meet one of the corrosion protection standards listed previously or meet one of the following upgrade options: interior lining, CP, or internal lining combined with CP, or be properly closed. Prior to adding CP, the tank integrity must be ensured using one of the following methods:

• The tank is internally inspected and assessed to ensure that the tank is structurally sound and free of corrosion or holes.

• The tank has been installed for less than 10 years and uses monthly monitoring for releases.

• The tank has been installed for less than 10 years and is assessed for corrosion holes by conducting two tightness tests—the first occurs prior to adding CP and the second occurs three to six months following the first operation of CP.

• Alternative integrity assessment: the tank is assessed for corrosion holes by a method that is determined by the implementing agency to prevent releases in a manner that is no less protective of human health and the environment than those listed previously.

Upgrading bare metal piping is accomplished by adding CP. Metal pipe sections and fittings that have released product due to corrosion or other damage must be replaced. Piping entirely made of (or enclosed in) noncorrodible material does not need CP.

New Rules Seek Better Leak Prevention, Detection

In July 2015, to strengthen federal UST requirements so prevention and detection of petroleum releases from USTs are improved and help ensure all USTs in the United States meet the same release protection standards, the EPA made several revisions to the 1988 UST regulation and the 1988 state program approval (SPA) regulation.4

Changes to the regulations include:

• Adding secondary containment requirements for new and replaced tanks and piping

• Adding operator training requirements

• Adding periodic operation and maintenance requirements for UST systems

• Addressing UST systems deferred in the 1988 UST regulation

• Adding new release prevention and detection technologies

• Updating codes of practice

• Updating state program approval requirements to incorporate these new changes.

As of April 11, 2016, when installing or replacing tanks and piping, owners and operators must install secondary containment, which means the tank and piping must have an inner and outer barrier with an interstitial space that is monitored for leaks, and includes containment sumps when those sumps are used for interstitial monitoring of the piping. Interstitial monitoring must be used as release detection for these new or replaced tanks and piping. Automatic line leak detectors are still required for new and replaced pressurized piping. 5

Under-dispenser containment (UDC) for all new dispenser systems must be installed as of April 11, 2016. UDC containment is containment underneath the dispenser system designed to prevent leaks from the dispenser and piping within or above the UDC from reaching soil or groundwater. UDC must be liquid-tight on its sides, bottom, and at any penetrations. It must allow for visual inspection and access to the contained components or be periodically monitored for leaks from the dispenser system. 5

The docket for the UST regulation is EPA-HQ-UST-2011-0301-0450 and can be accessed at regulations.gov.

Corrosion Protection for USTs: An Overview

According to the EPA,2 unprotected underground metal components of the UST system—tanks, piping, and metal components such as flexible connectors, swing joints, and turbines—can corrode, and holes caused by corrosion can lead to product releases. Corrosion can begin as pitting on the metal surface, and holes may develop as corrosion continues and pits become deeper. Over time, even a small corrosion hole can release a significant amount of product. All metal UST system components that are in contact with the ground and routinely contain product must be protected from corrosion. The two common methods used for protecting metal components from corrosion are isolating the metal component from the corrosive environment and CP.

Tank Linings

A structurally sound tank interior may be lined with a thick layer of noncorrodible material, as long as the lining material and application method comply with applicable industry codes. The lining used must also meet the same federal requirements as for repaired tanks (40 CFR 280.33). Flexible inner liners (bladders) that fit inside a tank do not meet the tank interior lining requirements. Tanks using only an interior lining for corrosion protection must pass an internal inspection within 10 years and every five years after that to ensure the tank and lining are sound. Records of these inspection results should be kept.

Cathodic Protection

A CP system—either a sacrificial anode or impressed current system—is another option for protecting UST from corrosion. Sacrificial anodes can be attached to a coated steel UST for corrosion protection; however, the coating must be a suitable dielectric material (i.e., a coating that electrically isolates the UST from its environment and meets applicable industry codes. An asphaltic coating is not considered a suitable dielectric coating). Sacrificial anodes are more electrically active than the steel UST. Because these anodes are more active, the attached anode is sacrificed while the UST is protected. Depleted anodes must be replaced for continued corrosion protection of the UST.

An impressed current CP (ICCP) system uses a rectifier to convert alternating current (AC) to direct current (DC). This current is sent through an insulated wire to the anodes, which are buried in the soil near the UST. The current then flows through the soil to the UST system and returns to the rectifier through an insulated wire attached to the UST. The UST system is protected because the current going to the UST system overcomes the corrosion-causing current normally flowing away from it.

Federal regulations require that the field-installed CP systems at UST sites be designed by a corrosion expert. Within six months of installation and at least every three years thereafter, the CP system must be tested by a qualified CP tester. An ICCP system must be inspected every 60 days to verify that the system is operating. Additionally, within six months of a repair to any cathodically protected UST system, the CP system must be tested. The results of the last two tests must be kept to prove that the sacrificial CP system is working. Results of the last three 60-day inspections must be kept to verify the ICCP system is on and operating properly.

Tank Lining Combined with Cathodic Protection

Applying both an interior lining and CP is another option for upgrading existing tanks. Combining the two corrosion protection systems has several advantages: the USTs receive greater corrosion protection and the condition of the interior lining does not require periodic inspection. While these advantages can amount to significant cost savings over using an interior lining alone, the CP system must periodically be tested and inspected to ensure it is working properly. Records of these tests and inspections must be kept.

Source: U.S. Environmental Protection Agency, web site: www.epa.gov.

References

1 “Implementation Time Frames for 2015 Underground Storage Tank Requirements,” EPA, https://www.epa.gov/sites/production/files/2015-09/documents/implementbrochure091515.pdf (March 29, 2018).

2 “Underground Storage Tanks (USTs),” EPA, https://www.epa.gov/ust (March 29, 2018).

3 Underground Storage Tanks (USTs), Release Prevention for Underground Storage Tanks (USTs), “Corrosion Protection,” EPA, https://www.epa.gov/ust/release-prevention-underground-storage-tanks-usts (March 29, 2018).

4 Underground Storage Tanks (USTs) “Revising Underground Storage Tank Regulations-Revisions to Existing Requirements and New Requirements for Secondary Containment and Operator Training,” EPA, https://www.epa.gov/ust/revising-underground-storage-tank-regulations-revisions-existing-requirements-and-new (March 29, 2018).

5 Underground Storage Tanks (USTs), Secondary Containment and Under-Dispenser Containment—2015 Requirements, EPA, https://www.epa.gov/ust/secondary-containment-and-under-dispenser-containment-2015-requirements (March 29, 2018).