Initial test results have shown higher corrosion resistance, increased mechanical strength, and better abrasion resistance when using epoxy resin-based coatings formulated with graphene in lieu of traditional zinc to protect against corrosion on steel substrates.

Mark Thompson, managing director of technology materials company Talga Resources (West Perth, Western Australia, Australia), says tests using the company’s branded graphene, Talphene,† have shown superior results when tested against reference epoxies and commercial zinc-rich epoxies.

“Most large-volume steel anticorrosion coatings are made from epoxies, so that’s where we’re targeting first,” Thompson says. “Marine coatings could be positively impacted by this stuff. Then the composite carbon-fiber resins will follow.”

So far, the tests have used a formulated dispersion of the company’s few layered graphene and graphene nanoplatelets, mixed in a proprietary way into a two-party epoxy resin widely used in marine coatings.

“By substituting current active ingredients such as zinc with lower quantities of non-toxic graphene alternatives, the application, environmental, and maintenance costs of steel infrastructure can be reduced,” Thompson says. “We think over time, a lot of the zinc [used in epoxies] can be replaced.”

Benefits of Graphene

According to Thompson, graphene offers desired qualities including high strength-to-weight ratio, impermeability, and chemical inertness. These characteristics have been shown to result in additional corrosion protection and more environmentally friendly polymer matrixes when used as an additive. He says graphene contains several other benefits, including a high aspect ratio and functionalization to provide passivation reactions, both anodic and cathodic protection (CP), depending on the substrate.

“It’s a powerful anticorrosion tool, if it’s done right,” Thompson says. “It does require intimate knowledge of the chemistry so that it hooks up chemically with both the resin system and underlying metal substrate. You need to functionalize the graphene properly. The fundamentals of graphene’s passivation effect are poorly understood, but it is hypothesized the graphene takes electrons off the substrate and into the coating, thereby reducing the electron interaction,” Thompson says of the passivation potential. “But depending on the substrate it appears to be a tunable effect,” he adds, referring to CP.

In that way, graphene-enhanced epoxies can offer additional versatility by having the flexibility to be used on substrates of varying

conditions.

Improved Dispersion

Thompson says his company has found a route via a new patent-pending method to distribute the particles into epoxies in a much more homogenous manner.

“Our technology relates to both the formulation and, importantly, the method of incorporating the graphene into the epoxy to

maximize its effectiveness,” Thompson says.

Led by Cambridge, United Kingdom-based chief technology officer Siva Bohm, the company believes its new dispersion method could also be applied to other systems besides epoxies—including fiber-reinforced polymer composites—that have also suffered in the past from homogeneity issues with graphene.

“Delayed graphene dispersions have been a problem for a long time,” Thompson says. “You can’t disperse in these viscosities very well, and the curing time reactions are also a factor. To get the physical particles to be homogenously distributed at a nanoscale, while minimizing workability changes, that’s been the holdup. We think this is the game changer.”

Corrosion Test Results

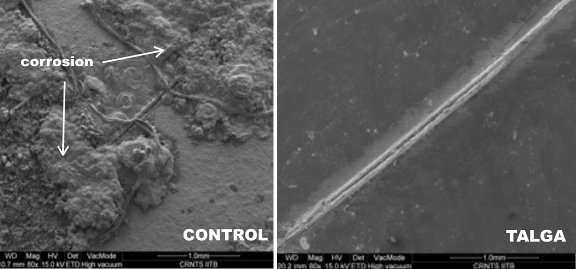

To test the corrosion-resistant properties, Thompson’s team used an epoxy resin system using bisphenol A (BPA) (C15H16O2) as the base matrix. Formulations containing graphene in various concentrations were incorporated with the base matrix and applied on standard mild steel panels for performance testing. A free film of each formulation was also made to evaluate tensile properties.

Meanwhile, a commercially available zinc-rich epoxy primer at 75 vol% zinc was used as the control variable for the corrosion evaluation, which consisted of electrochemical tests utilizing electrochemical impedance spectroscopy, linear polarization, and salt spray, as specified in the ASTM G591 standard.

“Within the first 500 hours of salt-spray testing, there was practically zero corrosion of the graphene-enhanced unit,” Thompson says. “The measureable one was the electrochemical evaluation, and that was a decrease in the corrosion rate of the underlying steel by two orders of magnitude when compared with the zinc-rich coatings.”

The abrasion resistance of the coating, tested under the ASTM D40602 standard, improved by 80% relative to the control coatings. Similarly, a 160% improvement in tensile strength and 95% boost to elongation were seen when testing the free film.

Thompson said his company would not yet disclose which graphene vol% formulation achieved those figures, adding that the project remains in development. However, he says there was a “significant impact” with even a 1 vol% graphene addition.

“It’s a massive decrease in the overall corrosion rate,” Thompson says, adding that the thickness of zinc-rich coatings may be reduced if using graphene, reducing overall volume requirements.

Next Steps

Going forward, the company says it recently entered into a product development agreement with independent materials and research group The Welding Institute (TWI) (Cambridge, United Kingdom) to further develop and validate the technology.

“They’re a really respected materials development institute, and we’re now working with them on increasing the range of performance and having their outside validation of what we found,” Thompson says. “Once that matures and gives us a bigger amount of data for industry, we go out looking for coatings industry partners, such as one we have already with Chemetall [Frankfurt, Germany], a subsidiary of BASF's coatings business, on graphene-enhanced metal pretreatments.”

Meanwhile, in the company’s own labs, the next stage of research will investigate whether the graphene additive technology can be successfully applied to other composite resin systems in addition to epoxies.

“We do have indications from some lab work that other systems will respond similarly,” Thompson says. “Others are conceptual at this stage. But we have good reason to believe this will expand and be around for a while.”

Source: Talga Resources, www.talgaresources.com. Contact Mark Thompson, Talga—email: mark@talgaresources.com.

† Trade name.

References

1 ASTM G59 (2014), “Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements” (West Conshohocken, PA: ASTM, 2014).

2 ASTM D4060 (2014), “Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser” (West Conshohocken, PA: ASTM, 2014).