There exists a need in the oil and gas, power, marine, and water industries, among others, for a multi-functional polymeric coating to preserve aging infrastructure and extend the service life of existing assets. Historically, anticorrosion coatings include high standard surface treatment and application requirements, which aren’t conducive to resources already in service. To apply these coatings, the existing coating system must be completely removed, leading to downtime and health, safety, and environmental (HSE) concerns.

Because of these drawbacks, an unconventional, anticorrosion protection system was created. It is viscoelastic, easy to apply, has few HSE concerns, protects against extreme environments, requires little surface preparation, and has a long service life. Researcher Kaveh Sarikhani with Canusa-CPS, a ShawCor Ltd. Company (Etobicoke, Ontario, Canada), evaluated this novel, cold-applied coating system through conventional and non-conventional test methods based on current industrial standards and performance specifications.

Through proper selection of rehabilitation coatings, industries can prolong the life of aging, exposed infrastructure that is at risk of, or experiencing, corrosion. Unfortunately, most rehabilitation coatings require surface treatment that is not only complex, but costly. This is impractical for assets already in service, but this new coating system enables continued operation during rehabilitation, extending the life of the assets. The new multi-functional system is viscoelastic, can reflow into a damaged area, and is self-healing.

Viscoelastic coatings are able to instantly bond to surfaces without the need for much surface preparation, nor do they require preheating or curing time. Solutions can be tailored to specific problems by adding additional layers that provide extra protection, depending upon the need.

Viscoelastic coatings are amorphous and inert, so they maintain their wetting properties after installation. This is advantageous because the adhesive compound can flow into cervices and pores, which increases the contact surface area.

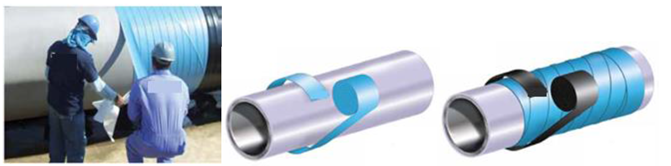

Figure 1 shows how the viscoelastic coating is applied onto steel. Furthermore, in comparison with paint, these coatings do not require any heavy equipment, pretreatment, cure times, and are “low complexity.” They are water resistant and reduce rust creep; and they do not contain any volatile organic compounds (VOCs).

Figure 1 shows how the viscoelastic coating is applied onto steel. Furthermore, in comparison with paint, these coatings do not require any heavy equipment, pretreatment, cure times, and are “low complexity.” They are water resistant and reduce rust creep; and they do not contain any volatile organic compounds (VOCs).

To study this novel coating system, Sarikhani tested it on various substrates ranging from smooth to grit blasted, on both curved and flat segments. Testing methods conducted included adhesion testing at ambient and coating rated temperatures, determining non-crystallinity, hot water immersion and thermal aging, and impact resistance.

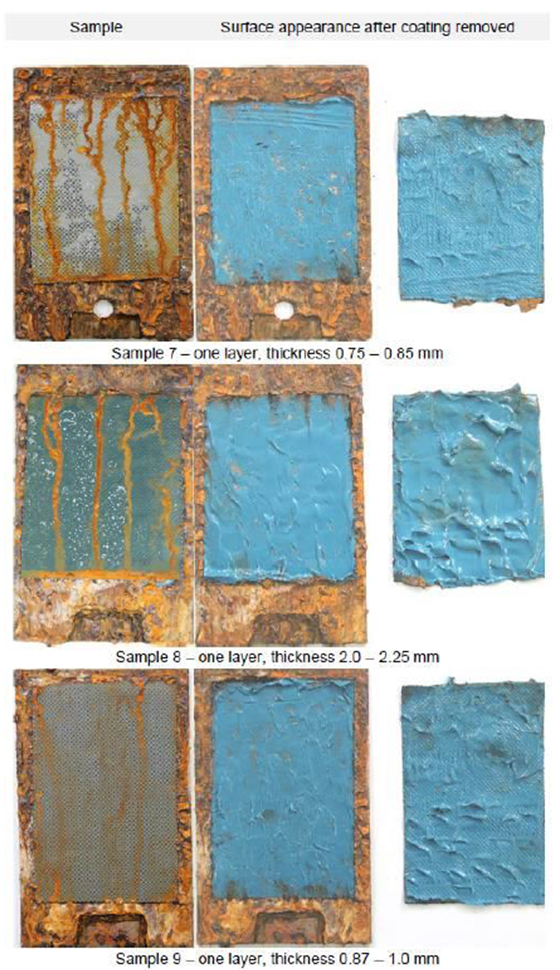

Non-standard tests were also performed such as salt water immersion, peel adhesions tests, and salt spray exposure (Figure 2, top, and Figure 3, bottom). These helped determine the level of corrosion protection the system provides, as well as its durability in adverse environments.

Testing proved that the novel viscoelastic coating system was able to withstand direct exposure to salt water, even when submerged for a significant time, while preserving its strength and anticorrosion functionality. Additional findings show that it is rated for 720 h under NSS with the coating remaining intact with no corrosion creep observed at the edges of coated panels. It is amorphous and self-healing without losing significant adhesive strength over time under accelerated hot water immersion tests and thermal aging studies, demonstrating a calculated lifetime of over 25 years.

Research also found it to be compatible with various levels of surface preparation and substrates while providing instant tackiness upon contact. Another noteworthy benefit is the HSE and ease-of-application features facilitated by this coating system, allowing in-service rehabilitation and reducing the amount of space and equipment needed for installation.

The viscoelastic compound lends itself to several installation conditions, and combining it with an outercoat facilitates an abundance of operating and environmental exposure conditions in its ultimate use. Unlike paint, testing has proven viscoelastic coatings to be easy to apply, usable in hot and cold climates, do not require much installation equipment, and can be applied to active infrastructure/pipes. It adheres quickly to bare substrate or to existing coatings and is self-healing (even if damaged), protecting an area of exposure until repairs can be made.

Final benefits include the HSE properties in which limited personal protective equipment is needed, no VOCs are present, no chemicals are leached into the surrounding environment, and it is safe to store and to handle, requiring no regulations for disposal.

Sarikhani notes that further studies (such as dielectric constant measurement and performance at lower temperatures) should be performed on these novel viscoelastic coatings to determine their capabilities and application extremes.

This article is based on CORROSION 2021 paper no. 16731, presented virtually.