The development of corrosion on metal piping or under insulation presents a major source of risk for industrial facilities, especially offshore oil and gas sites.1 Damage caused by corroded pipes can lead to unexpected facility downtime and expensive repairs. Corrosion under insulation (CUI) also may increase safety risks for employees and the environment from hazards including fire and explosions.

Factors Raising the CUI Threat Level

While the presence of any moisture heightens the risk of corrosion developing, moisture with an acidic or basic pH increases the potential for CUI. Temperature also may alter the risk of corrosion, and the primary temperature danger zone spans -4°C (25°F) to 175°C (350°F).2 However, warmer systems can be at risk from CUI development during downtime or cycling when temperatures drop and moisture has the opportunity to condense. Moisture can be introduced into pipe systems multiple ways, including through condensation, precipitation, seawater deluge, leaks, cooling tower drift, sprinklers, and routine cleaning.

Additional factors at a facility that can contribute to CUI risk include the degradation of joints and joint sealants, along with insufficient maintenance of cladding.

Employing Insulation Technologies to Reduce CUI Risk

Most risk-reduction strategies work by keeping water out of the system, changing the chemistry of moisture present, or by providing moisture a planned exit pathway. To make the best use of available technologies and establish a long-term CUI mitigation strategy, several questions may need to be answered. What kind of insulation is being used? Does the material retain, wick, or absorb moisture? And, does the material perform in the necessary temperature range?

Using a 100% closed-cell, impermeable insulation like FOAMGLAS® cellular glass insulation can help reduce both how much moisture enters a system and how long it is retained. The material also has an inert chemistry that provides few chlorides and can be easily fabricated into multiple shapes and configurations.

However, some facilities may conclude that moisture invasion cannot always be prevented. Planning for that possibility can provide a way to limit consequences.

Planning an Exit for Moisture

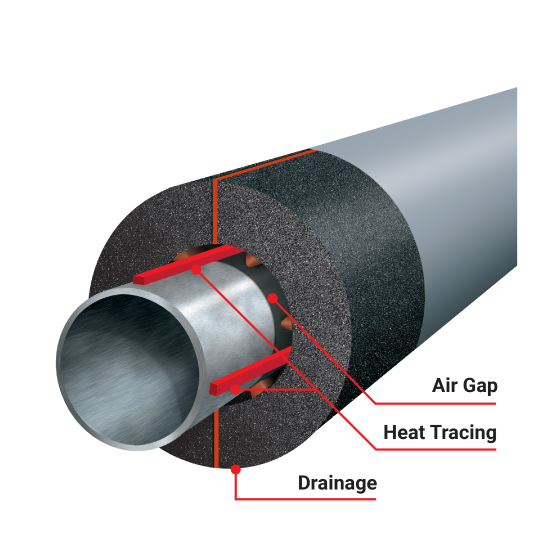

One strategy for managing moisture in an insulated system is to use non-contact insulation to provide a path for moisture to drain away from metal piping. FOAMGLAS® insulation can be paired with spacers to create an air gap that allows water to funnel out of an insulation system through drains.

The spacers and termination strips are molded from high-temperature, high-performance silicone using exclusive RTV technology. The geometry and shape are designed to help shed water away from the piping surface. Termination strips, combined with the impermeability of cellular glass insulation, allow the system to be compartmentalized.

The spacers create a 0.5-inch (12mm) space between the inner wall of the insulation and the pipe. The spacers and strips can be used in systems with continuous temperatures ranging from -50°C (-58°F) to 200°C (392°F) or in intermittent scenarios reaching up to 250°C (482°F).

The spacers and termination strips are secured to the insulation using PC® HI-TEMP RTV Silicone Adhesive. This one-part, neutral cure, high-temperature silicone adhesive is formulated for use with FOAMGLAS® Insulation Systems and provides exceptional adhesion. The system’s joints are sealed using PITTSEAL® HI-TEMP LV RTV Sealant. This one-part, neutral cure, low-viscosity sealant efficiently spreads to help seal FOAMGLAS® insulation.

Using Insulation Systems to Manage Heat and Sound

The FOAMGLAS® Spacer System can be used in multiple applications where CUI is a concern. The system was designed for use in hot or above-ambient facilities with continuous or nearly consistent operations where water intrusion from secondary sources is probable.

Moisture can create problems in hot systems, as pipe insulation closer to the jacket may be cooler than the insulated pipe and allow for condensation to collect if the material is not impermeable. Water collection in the outer surface of insulation may reduce thermal performance and temperature control in addition to increasing the risk for CUI. When insulation retains moisture, it can alter energy consumption and surface temperature, and may negatively influence personnel safety along with raising facility operating costs.

Additionally, the gap established for moisture channeling also provides space for heat tracing. FOAMGLAS® insulation helps maintain temperature control inside pipes and reduces the influence of external elements. The FOAMGLAS® Spacer System directs moisture away from piping while providing a path to remove moisture from the system, potentially helping prevent damage to tracing and solidification within the pipes. Solidification may occur when insulation efficiency is lost or heat-traced lines cease operating effectively.

The system also provides strong acoustical properties. Configurations of the combined technologies meet ISO 15665 Class A and B standards. Since its introduction, the FOAMGLAS® Spacer System has been implemented by several operators of marine and offshore facilities in the North Sea.

Planning for Improved Control, Reduced Worry

The development of CUI in a facility can carry many consequences, costing time, money, and safety. However, it is possible to plan for CUI and understand locations where it would be more likely to develop. Steps – like correctly selecting, installing, and maintaining an appropriate insulation system – can be part of a comprehensive strategy to mitigate CUI.

For more information, or to contact our technical services team, visit: https://www.foamglas.com/en-us/advice-center/general-advice/systems-for-cui-mitigation.

1NACE International. 2016. “International Measures of Prevention, Application and Economics of Corrosion Technologies Study.”

2NACE International. 2010. “Standard Practice: Control of Corrosion Under Thermal Insulation and Fireproofing Materials – a Systems Approach.”