When designing process facilities, the selection of the insulation system is an important factor. Improper choices can not only lead to underperforming insulation systems, but also contribute to issues associated with corrosion under insulation (CUI).

Consequences associated with CUI include: unanticipated failure of the process, damage to equipment, costly repairs, downtime, increased potential for leaks, and even fire. Selection of the appropriate type of insulation for the system design is significant for mitigating CUI.

There are three primary conditions which are necessary for CUI to occur:

Moisture must be present for corrosion to occur. Common sources of moisture are condensation, cleaning, process leaks, precipitation, ice melt and fog. Moisture can saturate permeable insulations or become trapped under impermeable materials. The corrosion rate under wet insulation can be up to 20-times greater than the corrosion rate in the ambient atmosphere.

Chemical content of the moisture can cause issues for both carbon and stainless steel. Local pollution, the insulating material or other components such as sealants, coatings and jacketing can change the pH of the moisture, resulting in an acidic environment beneath the insulation system. Chlorides may be present in salt water environments, or leached from insulation systems.

Temperature. Service temperatures from 32°F – 212°F (0°C – 100°C) allow water to exist as a liquid. In this range, the corrosion rate can potentially double for every 27°F (15°C) increase in temperature. Additionally, cyclic process conditions can accelerate corrosion rates. Even when process conditions are above 212°F (110°C), moisture can be harbored in permeable insulations, concentrating chlorides and ready to react at the next cooling cycle.

What are common methods for protecting processes against CUI?

There are a variety of approaches that can help limit corrosion under insulation. Preferences will vary depending on process conditions and other environmental factors.

Vapor retarders can be effective when used over rigid insulation materials, but can be susceptible to damage or perforation. The quality of vapor retarder materials can also vary widely.

The use of coatings or foils. Paints, mastics, gels or other coatings are often used as barriers to water entry. Often, surface preparation is critical, and defect-free coating may be difficult to achieve. Foils are sometimes used as a physical barrier and for cathodic protection.

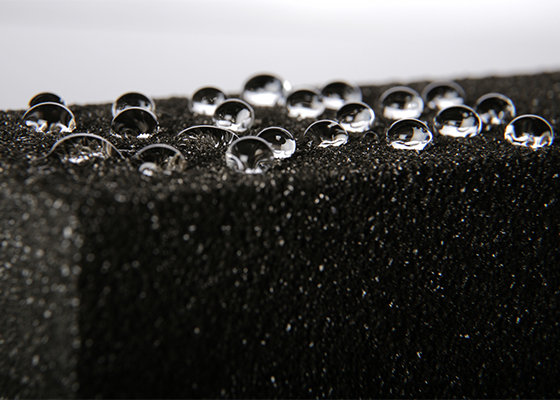

Insulation system selection. The use of an insulation system that helps prevent water intrusion and will not retain water has been shown to be an effective means for mitigating CUI.

Additionally, the use of gap technology to maintain a void between the insulation system and process equipment to help prevent water from collecting against the pipe has been shown to be effective under certain conditions. This methodology has been adopted by numerous offshore facilities.

FOAMGLAS® Cellular Glass Insulation Systems

Cellular glass is an impermeable insulation material and will not absorb water. FOAMGLAS® cellular glass insulation, when applied according to guide specifications, minimizes water intrusion and retention.

FOAMGLAS® insulation and accessories are designed for these types of applications, and do not contribute to corrosion of carbon or stainless steel. FOAMGLAS® insulation and many accessories have minimal water-soluble chlorides, and have been tested and certified as acceptable for use with austenitic stainless steel.

Process system designers often choose a FOAMGLAS® insulation sealed system, developed to help keep moisture out and limit CUI. An additional option is the use of the FOAMGLAS® Insulation Spacer System, which creates an air gap between the insulation and pipes to help minimize potential for water to remain in contact with the pipe under certain conditions. The Spacer System also provides a means for water to exit the system through drain holes.

FOAMGLAS® insulation offers long-term thermal performance combined with a wide service temperature range of -450°F to 900°F (-268°C to 482°C). For decades, it’s been selected as part of corrosion control strategies for major facilities worldwide – from North Sea platforms, to marine facilities on the Gulf Coast, to petrochemical refineries across the world. Help protect your processes by making FOAMGLAS® insulation part of your corrosion control strategy.

Contact our Technical & Training or Sales teams at 1-800-327-6126, or visit www.foamglas.com for more information.