INEOS Enterprises recently announced its acquisition of Ashland Composites; the new partnership is expected to have a major impact on the fiber-reinforced polymer (FRP) composites industry. Under INEOS Composites, engineers and end users will continue to have access to Ashland Composites’ technical expertise and the proven performance of Derakane resins. This expertise will now be coupled with the service and commitment of INEOS, one of the world leaders in science and chemistry.

INEOS Composites manufactures and sells a broad range of general-purpose and high-performance grades of unsaturated polyester and vinyl ester resins, and gelcoats for the FRP industry.

These products deliver an array of functional properties including corrosion resistance, fire retardance, ultraviolet resistance, water and chemical resistance, high mechanical properties, thermal and electrical insulation, impact and scratch resistance and high strength-to-weight ratios.

With the acquisition, those in the composites industry will now gain access to trusted brand names, such as Derakane resins and products on which they rely under the new INEOS Composites umbrella.

DERAKANE™ SIGNIA™ EPOXY VINYL ESTER RESINS

Also joining the INEOS Composites family is Derakane™ Signia™, an epoxy vinyl ester resin formulated for continued corrosion performance wherever FRP pipes and tanks are used.

Built on the same foundation as the legacy Derakane™ product line, Derakane™ Signia™ leverages new production capabilities to modernize resin features and benefits, including improved environmental performance, more efficient processing and increased worker satisfaction. Additionally, Derakane™ Signia™ resins encompass the industry’s first identifiable resin system, providing assurance that the resins specified were used and supplied for a project.

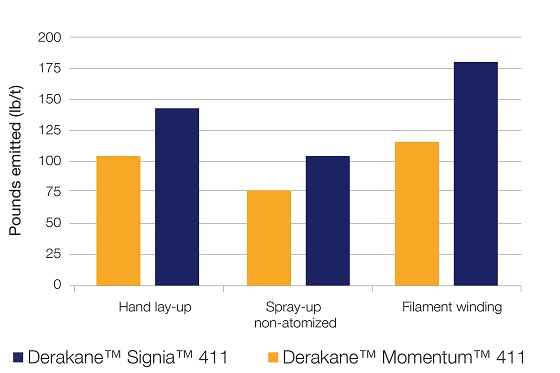

Reduction of styrene emissions has gained importance to the FRP composites industry over the past several years with increasing regulations around the globe regarding human exposure to styrene. Reduced styrene emission improves environmental compliance and also improves the work environment for FRP manufacturing. As a result, Derakane™ Signia™ resins are formulated to include unique vapor suppression technology that greatly reduces styrene emissions upon curing.

The vapor suppressant film is air activated and requires air to pass over the laminate surface; therefore, the fabrication method used greatly affects suppression performance of the resin system. Once formed, this suppressant film creates a barrier to block the evaporation of volatile compounds like styrene. Derakane™ Signia™ resin contains 44% styrene, but the vapor suppression technology allows it to perform the same as resins with far less styrene. This results in a minimum 30% reduction in styrene emissions, depending on the fabrication method.

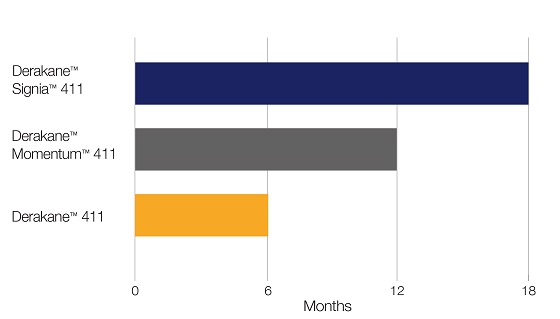

Reduced odor and less dust help provide a better overall work environment for employees, and a longer shelf life significantly extends the workability timeframe. According to the company, these resins offer a 50% longer commercial warranty compared to current epoxy vinyl ester resins and nearly three times the warranty of the original Derakane™ line .

FRP fabricators count on Derakane™ epoxy vinyl ester resins for proven performance backed by decades of documented in-service reliability. Derakane™ Signia™ resins deliver improved productivity with faster laminate consolidation, lower foaming and reduced sanding for application of secondary laminations.

In Derakane™ Signia™ resins, INEOS Composites has combined the best technological features of the Derakane™ and Hetron™ lineage with additional new learnings to bring landmark improvements that elevate the quality, production and supply of high-quality FRP composite equipment.

Driving the Industry Forward, Together

INEOS recognizes the profound impact Ashland Composites had on the composites industry and paired with the expertise of INEOS, together they are continuing to raise the standard and drive the industry forward.

To learn more about INEOS and the future of composites, visit ineos.com/composites