Over the past decade, you’ve likely heard plenty about the PHMSA Mega Rule. As new regulations roll out, it’s vital to assess how they’ll impact your operations and what steps to take to be in compliance.

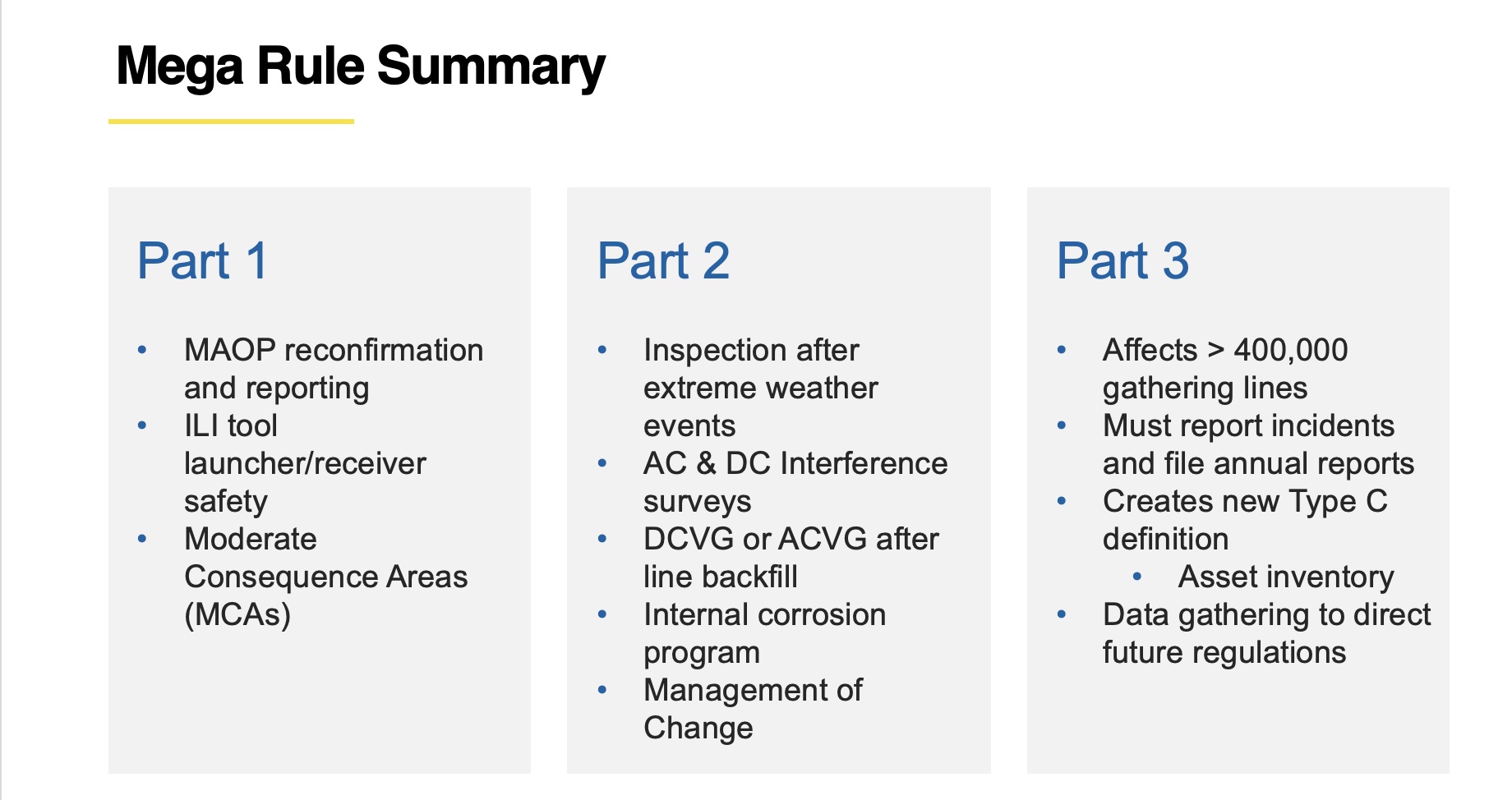

The Mega Rule is the most sweeping regulatory change the pipeline industry has seen since 49-CFR 192 was introduced. It’s so comprehensive it had to be broken into three parts. Part One went into effect in 2020.

Whether you’re catching up on the details or starting to research next steps for your natural gas assets, check out our guide to complying with the PHMSA Mega Rule.

Mega Rule: A Brief History

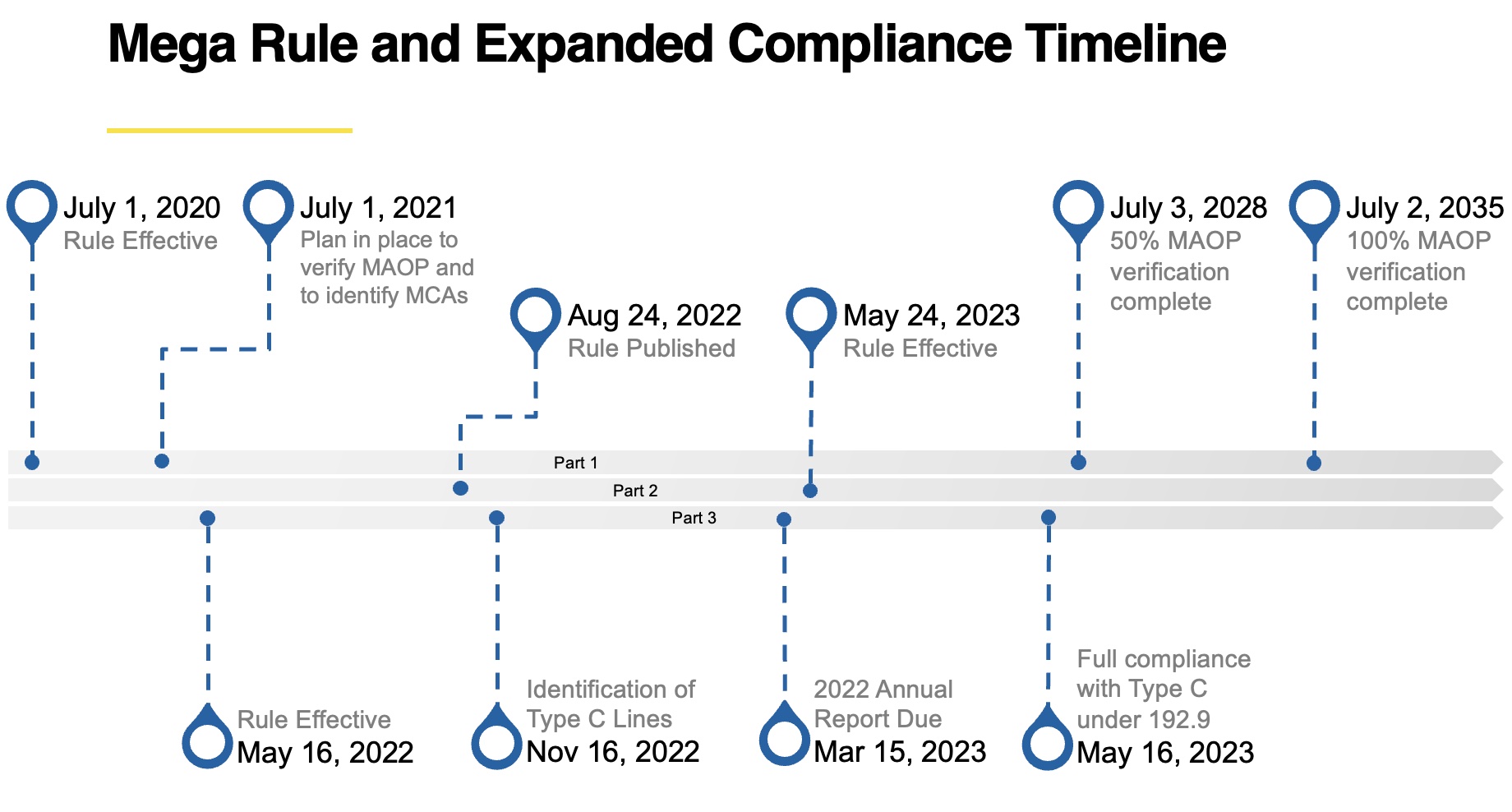

PHMSA released its third and final rule to the public on August 4, 2022. It was published August 24, 2022. This regulation is largely the product of negotiations with a diverse group of stakeholders, including industry, citizen groups, and industry trade groups. The bulk of the rule’s requirements takes effect May 24, 2023.

We’ll start with an overview of Part Three because it is the most recent rule to go into effect. We cover Part One next as it went into effect with some 2021 deadlines. Finally, we’ll discuss Part Two, which has yet to become effective but is coming.

Mega Rule Part Three

Part Three focuses on PHMSA’s oversight reach. Previously their authority covered transmission and some 11,661 miles of onshore gathering pipeline. The new regulation extends coverage to the first valve off the production facility. That brings an estimated additional 426,000 miles of pipeline under PHMSA’s jurisdiction. Of this mileage, PHMSA estimates 90,863 miles will classify as Type C gathering, which qualifies for more stringent regulatory treatment.

Most pundits had expected Part Two to be effective in 2021, with Part Three finalized sometime in 2022. However, Part Three was published August 24, 2022, with an effective date of May 16, 2022.

The executive summary of the final rule notes the driver behind accelerating Part Three enforcement is new drilling technologies, surging gas production, and a corresponding increase in volume transported by gathering lines.

PHMSA further noted that “large diameter, high-pressure gathering lines are susceptible to the same types of integrity threats as transmission pipelines, including corrosion, excavation damage, and construction defects. The exemption of these pipelines from the safety requirements of the Federal Pipeline Safety Regulations failed to consider the present risks that now exist.”

Part Three puts a significant new reporting burden on operators with new guidelines for classification of gathering lines and a corresponding incident tracking and reporting requirements.

Achieving Part Three Compliance

If you are new to PHMSA, reaching full compliance under Part Three can be overwhelming.

We can help start or expand your compliance program by leveraging our mobile data CartoPac Enterprise solution to digitize your entire pipeline system. We’ll map center lines and everything you need to be compliant.

With a comprehensive approach to identifying, assessing, providing expertise, hardware and software, and providing mitigation and other hands-on services, American Innovations is here to help.

Mega Rule Part One

Part One of the Mega Rule covers a variety of new regulations including Maximum Allowable Operating Pressure (MAOP) verification and the identification of new extended covered segments of pipelines called Moderate Consequence Areas (MCA).

Part One requires a long-term, focused effort to achieve compliance by 2035 and beyond. The best path forward is to choose the right technology to manage the traceable, verifiable, and completeness of the records you’ll need to comply.

Mega Rule Part Two

Part Two of the Mega Rule focuses on improving pipeline integrity management best practices. While it is not yet in effect, you will need to plan ahead for what will most certainly be significant required changes to your integrity, operating, and compliance procedures:

- Cathodic Protection: Gas pipeline operators must have an external corrosion management plan in place to limit the effect of electrical interference through surveying and assessment. They must then make efforts to mitigate this corrosion in a comprehensive manner alongside other test results.

- Close Interval Surveying & Assessment: If any pipe to soil measurements indicate that cathodic protection is below appropriate levels, the pipeline operator must conduct close interval surveys approximately every five feet in the affected area and remediate any issues within 12 calendar months.

- AC Interference Monitoring: Previously pipeline operators had to “consider” a recurring or continuous AC interference program to control and monitor accelerated corrosion due to power lines. Part Two now solidifies this request for “consideration” into a true requirement within six calendar months.

- Internal Corrosion: Pipeline operators must establish a continuous program to monitor and mitigate internal corrosion. If they find that the pipeline is actively transporting corrosive gas, they must check the affected areas at least twice annually using coupons or other relevant methods.

Achieving Part Two Compliance

There are components in Part Two of the Mega Rule that pipeline operators must address.

If you’re unsure of where to start, we can help you review your operations and best practices for cathodic protection. With our expertise and suite of hardware and software solutions PCS, you can easily update, document, and manage your records.

When it comes to internal corrosion, many pipeline operators have no current program. Suppose you don't know what your program should look like, what factors you may need to consider, or how and when to monitor your pipeline. In that case, we can create and develop a tailor-made continuous program based our mobile data collection solution CartoPac Enterprise.

With CartoPac Cathodic Protection, we can help you perform close interval surveys to gather data on your current CP needs, and turn those data into actionable insights.

Are you looking for a comprehensive approach to pipeline management and compliance with the PHMSA Mega-Rule? Contact us for a consultation: aiworldwide.com. More information can be found on the blog post here.