In a fast-changing world, engineers must seek innovative ways to support the circular economy, oriented to reach a better life with fewer resources. This article shows how profitability can be achieved to increase market value and business, while helping to become environmentally sustainable, reducing waste, and being more efficient. Merging concepts like designing for purpose, maintaining with integrity, and decommissioning with a second life in mind are ideas that, if used in conjunction with adequate management tools, can help industries pursue the correct path of applying an effective corrosion management system.

Currently, humankind is experiencing one of the biggest challenges regarding sustainability. Our planet is becoming less comfortable for all living species on it, including humanity. Recent studies show that “the current rate of warming is much faster than anything observed in the last 2,000 years.1 Contamination and environmental pollution are growing at unprecedented rates and reaching levels that pose severe risk to living species.

Global warming, increasing pollution, and several other phenomena are all interconnected. Energy consumption and water scarcity are related phenomena, as all are directly related to the extraction, consumption, use, and disposal of materials.

Appropriate and responsible efforts must be oriented to extend the time for return, reuse, redesign, and recycling in order to produce fewer residues, and ultimately, less pollution. Such efforts demand corrosion engineers who can support the new economic model—one oriented to look for profitability encompassed with sustainability. That means revamping current engineering practices and educating the new generation of professionals with a renovated curriculum, hoping that professionals will accept the challenge of gradually decoupling economic activity from the consumption of finite resources to designing waste out of the system.2

As the authors have in a recent paper,3 there are some engineering activities that gain relevance to maximize product usage and minimize the use of raw materials, time, and energy consumption. These include a more rigorous and adequate selection of materials; developing and maintaining better integrity, reliability, and maintenance programs; and researching and implementing more options for recovery, oriented to extend the time for i) product usage, ii) reuse, iii) recycling, and iv) production of minimal or no waste.

Working with these premises will result in fewer resources extracted, less manufacturing, fewer energy requirements and residues, and less pollution. This reconfiguration of product life cycles, combined with improvement of the financial performance of the companies through actions like proper equipment design and selection, use of renewable energy and materials, longer equipment life spans, improved efficiency of products, remanufacturing, and adequate management tools can help organizations move toward more efficient operation. Challenges to this emerging tendency are widespread and potential solutions must be widely discussed and addressed to ensure the right approaches are taken.

In summary, there is a group of tools to handle corrosion problems, but there are also many opportunities to develop new ones. The related problems, tools, and opportunities are enriched by the appearance of a group of emerging technologies, which converge to generate the so-called Fourth Industrial Revolution.

Circular Economy

“A circular economy (CE) seeks to rebuild capital, whether this is financial, manufactured, human, social, or natural. This ensures enhanced flows of goods and services.”2

One of the branches of the CE system is directly associated with the development of materials for the support of civilizations and the development of societies: the production of raw materials, their design, processing, use, protection, reuse, refurbishment, and recycling. In other words, the full spectrum of material engineering duties.

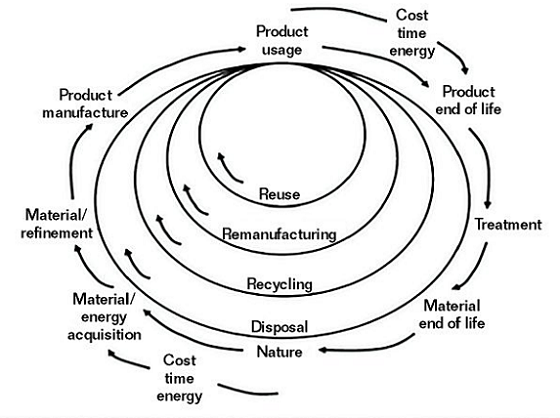

Nowadays, growing concerns about the sustainability of the planet are demanding radical changes in traditional methods of materials production, use, and disposal. This is the motivation for a proposed model of CE to replace the traditional linear model of materials handling. Figure 1 shows a close-up of the right side of the CE value circle, with emphasis on the use of materials, including the metallurgical–thermodynamic cycle from minerals to corrosion products. This means major expenditures of cost, time, and energy for transforming minerals into useful materials (nonstable conditions) at the left-hand side of the loop, followed by natural deterioration phenomena closing the circle (with loss of energy and gain of entropy) on the right-hand side of the loop.

The challenge is a progressive reduction of the importance of the outside cycles. In other words, the inner loops of reuse and remanufacturing are preferred because they require fewer natural resources, less energy, and are more economical. Time and value in terms of the resources spent within the inner circles should be maximized.4 That is exactly what happens when engineers take the challenge to create, implement, and improve tools to increase the synergy between productivity and sustainability.

Right now, the CE is calling for a new economic model oriented to seek profits on the right side of the outer and inner loops. The new model fosters entrepreneurial goals beyond economic profits to include environmental and social profits. Consequently the challenge is maximizing the time of usage or lengthening the replacement cycle (design for extended life or for as long as possible). The long life of equipment, its parts, and materials include easy reuse/redistribution and remanufacturing/refurbishing.

Tools for Corrosion Protection Management

Understanding and helping develop an organizational culture that supports corrosion engineers’ approaches can improve business competitiveness. In other words, creating new revenue can help to maintain the material supply and control and increase efficiency and productivity while connecting deeply with clients and consumers.

Management plays a key role in such initiatives through leading by example and affecting how all other organizational levels are equipped to face day-to-day challenges. Issues around processes, procedures, personnel training, continuous improvement, competencies by role, and key performance indicators (KPIs), among others, should be addressed as part of Tool One: a comprehensive corrosion management program.

Managers can create effective frameworks with achievable goals by using available tools appropriately. That is achieved by developing, supporting, implementing, and reviewing initiatives and plans that will help the corrosion/integrity management cycle create an organization that believes in and supports a culture of use, reuse, remanufacturing, recycling, and disposal. It requires implementing the right program at every stage of the equipment cycle, from conception to decommissioning, by designing out waste and pollution, keeping materials in use, and regenerating natural systems. In general, it entails designing for purpose, which includes:

• Proper material selection

• Quality control and assurance

• Holistic approach during design

• Confirming operating conditions

• Avoiding blind spots

o Corrosion control documents

o Integrity operating windows

o Optimization of inspection plans

o Targeted inspection methods

o Gather and analyze inspection/maintenance records

• Maintaining as appropriate

o Eliminating unnecessary maintenance activities

o Reducing planned maintenance and extend maintenance intervals, where justified

o Demonstrating safety critical elements performance

o Improving production availability

o Reducing operating costs

o Demonstrating the required reliability

• Acquisition of raw materials

• Refinement and product manufacturing

• Product usage

• Decommissioning

o Fitness for service

o Life extension

o Idling

o Abandonment

o Recycling

These considerations ensure that the risks from asset integrity associated with aging and life extension are controlled effectively.

Tool Two is to standardize the KPI to align with organizational rather than departmental goals. Three elements must be in perfect harmony to achieve success in any project: tools, processes, and people. For an organizational culture to be successful, we need the help of each individual in the organization. The best way to ensure that understanding and support exist is to develop, monitor, and enhance a solid KPI program.

Very often, project and maintenance/reliability department objectives are not aligned (e.g., capital expenditure vs. operational expenditure). We often see that, although the budget comes from the same company, the budget of each department affects the decisions made. Within the same organization, everyone should be part of the same team.

For this tool to be effective, progress must be measurable. How? The company’s personal performance plans are a great way to identify, follow, and measure progress in this area at all levels of the organization.

Finally, Tool Three is education. Quality education means better preparation for life. People must be educated to optimize the use and conservation of materials supporting the development of humankind. Specifically, specialized professionals dealing with corrosion and anticorrosion science and engineering must be trained to optimize materials consumption through the application of the available scientific and empirical knowledge.

Integrating the concepts of tomorrow into today’s programs will help engineers be prepared to think about the environmental dimensions of their work, including their role in promoting a CE. Yet environmental challenges and opportunities have social implications that should also be considered during the process of design, implementation, and management. By training engineers to see their work as sociotechnical, educators can train the next generations of engineers to think more deeply and broadly about their contribution to the CE.

Conclusions

A new economic model is emerging, supported by the so-called Fourth Industrial Revolution. This is a new formula driven by the risk of an unsustainable planet: the circular economy model. New, relevant questions are being asked that arise from the body of knowledge related to corrosion and anti-corrosion. There are old and new challenges for the corrosion and integrity communities, coupled with a significant increase in opportunities.

New conditions require both conventional and new skills, and new answers, too. This is why there are trends in corrosion engineering that seek to understand these new conditions, including practices like design for purpose, maintaining with integrity, and design for deconstruction.

Bottom line, ensuring a better corrosion management system is implemented not only helps reduce equipment failures, health, and environmental incidents and save money, but also helps ensure that all of the measures that can be taken from design to decommissioning of any asset avoid wastage of resources (materials, people, and money) and contribute to the CE concept.

There are many aspects of the new economic and development model that must be considered from a materials integrity point of view. Companies, governments, universities, and society in general require the strengthening of corrosion and protection activities, including deeper research, the fostering of related curricula, more regulatory mandates, and a greater awareness of industrial leaders and managers. Collective actions are needed that directly relate to simultaneous positive impacts on profitability and sustainability.

A toolkit including these good practices, as well as broad answers to the current challenges, will include three features:

• A program oriented to asset management in full agreement with the current possibilities and demands offered by the Fourth Industrial Revolution.

• The standardization of KPIs by organizational goals.

• A pertinent and broad educational program supporting the needs of engineers and other stakeholders.

References

1 R. Neukom, et al., “Consistent Multidecadal Variability in Global Temperature Reconstructions and Simulations Over the Common Era,” Nature—Geoscience (2019). Published online: July 24, 2019, https://doi.org/10.1038/s41561-019-0400-0.

2 Ellen MacArthur Foundation, Circular economy concept (2017): https://edubirdie.com/blog/what-is-circular-economy.

3 M. Hernandez, C. Arroyave, “Corrosion and Protection Challenges and Opportunities in the Frame of a Circular Economy,” C2020, paper no. 15039 (Houston, TX: NACE International, 2020).

4 J. Korhonen, et al., “Circular Economy: The Concept and its Limitations,” Ecological Economics 143 (2018): pp. 37-46.