Researchers with the U.S. Army Research Laboratory (ARL) and the U.S. Army Aviation and Missile Research, Development, and Engineering Center (Aberdeen Proving Ground, Maryland, USA) say they have successfully developed and tested1 acoustic emission (AE) sensors to detect frame damage on conceptual composite UH-60 Black Hawk aircraft.

Manufactured by Sikorsky (Stratford, Connecticut, USA), the UH-60 Black Hawk is a four-bladed, twin-engine, medium-lift utility aircraft line frequently used by the U.S. Army for its missions.2

According to the researchers, their discovery opens up possibilities for new onboard features that could alert flight crews to the state of structural damage like matrix cracking and coating delaminations on a real-time basis. In turn, this could allow corrective actions to be taken before failure occurs.

“Future Army airframe structures are required to be lighter, safer, and ultra-reliable,” says Mulugeta Haile, a U.S. Army research aerospace engineer. “To achieve these, the Army must adopt a combined strategy of implementing advanced structural design methods, improved structural materials, and integrated damage sensing and risk prediction capabilities.”

Limitations of Current Practices

According to Jaret Riddick, director of the Army’s Vehicle Technology Directorate, the Army currently sustains its fleet using a phase maintenance paradigm. This system is a periodic calendar-based practice that requires inspection and maintenance at fixed time intervals.

However, Army officials say this process is inefficient, costly, and also entails extended downtime. As such, the hope is that the new sensing network can enable condition-based maintenance or maintenance on demand, along with the potential to reduce the lifecycle cost of Army vehicles.

“The downtime due to routine inspection and maintenance represents the major fraction of the lifecycle costs of Army platforms, because we are not using the platform and we have to pay for inspection, which in most cases reveals no damage,” Riddick says. “So the idea is to integrate a reliable damage sensing network and perform maintenance only when necessary.”

No External Energy Source Needed

The Army says it began studying the AE process about two years ago, citing problems with alternative methods such as ultrasonic and radiography because they require an external energy source in the form of a directed wave.

“The external energy has the undesirable effect of interfering with other systems of the aircraft,” Haile says. “In addition, other methods are not as good in detecting early damage.”

In contrast, the passive, nondestructive sensing technique relies on energy initiated within the structure and is able to detect damage at the instant it occurs. According to Haile, AE is the transient elastic wave created when there is a rapid release of energy in a material—usually owing to plastic deformation, phase transformation, or material fracture.

“The novelty of the current work is that we introduced several new concepts on wave acquisition control and signal processing to recover damage-related information in networked acoustic emission sensors," Haile says. “The ‘Eureka!’ moment was when the sensing network consistently identified and located the initiation and progression of damage during a prolonged fatigue test that lasted over 200,000 cycles—a feat that has never been achieved before."

How the Sensing System Works

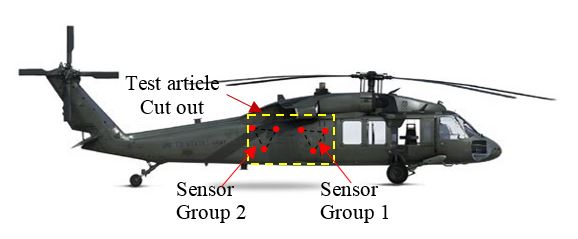

The ARL sensing network is comprised of 12 lightweight transducers encapsulated in three-dimensional (3-D) printed, non-intrusive sensor mounts. Applied in four groupings of three sensors, the Army says these sensors are distributed in multiple zones of the aircraft to maximize coverage and the probability of damage detection.

“Large-scale AE monitoring is a data-intensive process with several million hits being received by each transducer per flight,” Haile says. “This puts a higher load on the internal bus and circuitry of any data acquisition hardware. In general, most hits are not related to damage. Rather, they are noises from moving parts such as the clicking or rubbing noises of fasteners, panel connections, and vibrations from other non-damage related sources. Unwanted AE hits also arise due to reflections of an already received-and-processed AE wave. The challenge is to develop a system which is sensitive only to damage-related hits and insensitive to all other hits.”

To address these concerns, the Army’s data acquisition process is embedded with a software controllable timing parameter to reject reflections of a direct wave, as well as waves coming from non-damage related events. The time parameters are identified as reflection separation time and burst life time, and each is designed to minimize potential overlap in event reports.

Meanwhile, the signal processing algorithm for the AE system is augmented with a layer of adaptive digital filters to minimize the effects of any signal distortion that may occur on a mission.

“Most of the available AE-based structural health monitoring is for simple plate-like structures, despite most airframe structures not being simple plates,” Riddick says. “Not much has been done on integrated full-scale airframe health monitoring using AE. The problem is quite complex.”

Systems Engineering Approach

According to Haile, findings from AE-based monitoring should be immediately followed by a more detailed traditional inspection before any corrective actions are taken. However, based on adopting a systems engineering approach, significant time can still be saved because the AE system shows areas with the highest risk of damage for inspectors to focus on, rather than the entire aircraft.

Going forward, Haile says the next priority for the research community should be making the AE system better suited for large-scale use. For example, even with the timing control parameters used in this study, Haile explains that it is still not possible to accurately locate most hits recorded by transducers because techniques suitable for simple laboratory specimens are not transferrable to larger structures. As such, more effort needs to be put “into developing AE methods for monitoring large-scale, complex systems in realistic operating conditions,” he says.

Nonetheless, Haile says their findings show that with careful control of acquisition parameters and applying advanced signal processing techniques, AE monitoring can potentially be applied to air vehicles in the near future.

Source: U.S. Army, www.army.mil. Contact Mulugeta Haile—email: mulugeta.a.haile.civ@mail.mil.

References

1 “For the First Time, Army Sensors Can Detect Aircraft Damage as It Occurs,” Army Worldwide News, Nov. 16, 2017, https://www.army.mil/article/196971/ (Jan. 15, 2018).

2 “Sikorsky UH-60 Black Hawk,” Wikipedia, the free encyclopedia, https://en.wikipedia.org/wiki/Sikorsky_UH-60_Black_Hawk (Jan. 15, 2018).