It was once a belief among those industries that built the North American electric power transmission and distribution network that “if you build it from steel, it will last forever.” Today, the electric utility power transmission and distribution industry is building smart grids in North America and throughout the world to integrate with or replace the older electric utility networks; however, there are still many aging steel structures that could remain in service with the proper maintenance. To help utility companies develop the most appropriate inspection and maintenance programs for their steel structures, NACE International and the Institute of Electrical and Electronics Engineers (IEEE) have joined together to provide joint industry standards that address above-grade and below-grade corrosion of steel transmission and distribution structures.

According to the U.S. Department of Energy (DOE), the nation’s current electric grid was built in the 1890s and improved upon as technology advanced through each decade. Today, it consists of more than 9,200 electric generating units with more than 1 million MW of generating capacity connected to more than 450,000 miles (724,050 km) of transmission lines.1 There are an estimated 900,000 steel electric utility transmission and distribution structures in North America alone. Many of these steel structures were put into service during the economic boom years between 1950 and 1990 in the United States,2 and are ~45 years old. Some older structures, however, are reaching the 100-years-in-service mark.

Although the electric grid is considered an engineering marvel, its patchwork nature is getting stretched to its capacity. The DOE reports that 70% of the power grid’s transmission lines and power transformers are over 25 years old, with parts of the current network more than a century old, and the average age of power plants is over 30 years old. Today, the nation’s electricity needs are more sophisticated and the strain on the grid is greater than ever.3

“With a large and aging infrastructure, there is a high probability of critical failures of key structures unless comprehensive inspection, assessment, and maintenance plans are put into effect by all owners of the transmission and distribution system,” says NACE International member Cris K. Conner, vice president of Utility Service & Maintenance (St. Louis, Missouri) and vice chair and acting chair of the NACE Technical and Research Activities Committee (TRAC), as well as task group (TG) chair and vice chair of several current joint NACE and IEEE standards developing committees.

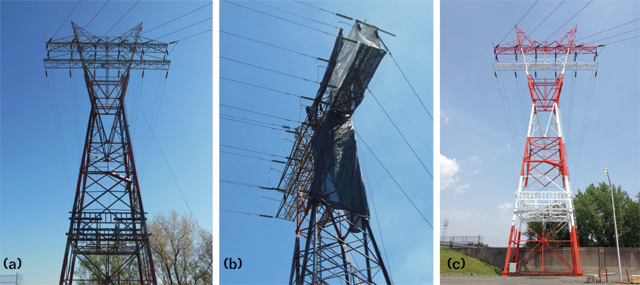

Imagine what 100-year-old steel must look like in the aboveground sections of these structures after years of exposure to a variety of often harsh climate conditions and pollution. Additionally, the below-ground sections present their own set of corrosion-related challenges. “The utility infrastructure is in rough shape,” says NACE member Curtis Hickcox, vice president, business development with Public Utilities Maintenance, Inc. (Watertown, Connecticut) and TG chair for two of the now published joint NACE/IEEE standards.

The age and condition of these structures dictates the need for inspection and assessment procedures to be incorporated into the owners’ maintenance programs to determine the level of corrosion.2 “You cannot put up a steel pole and forget it,” adds IEEE member Alan Holloman, vice president of operations, Power Grid Resources Inc. (Rica, Georgia) and a past TG chair for two of the now published joint NACE/IEEE standards.

New vs. Existing Steel Structures

The argument against implementing aggressive maintenance programs for electric utility transmission and distribution steel structures may have been based on the belief (now known to be misguided) that steel lasts forever. And under that assumption, more of a utility company’s capital expenditure dollars would be allocated for building more steel structures to keep up with the development of smart grids rather than developing more aggressive maintenance programs to extend the service life of its existing structures. “More utility money is available to build new structures, so maintenance often receives less funding,” Hickcox says.

That belief that steel has unlimited longevity is no longer valid, of course, as utility companies have watched their aging steel transmission towers and distribution structures succumb to the ravages of corrosion. Steel corrodes and requires regular inspection and maintenance; but, Hickcox comments, it’s often a budget issue that prevents utility companies from implementing a detailed maintenance program. Some maintenance projects can be very costly, such as the ones where lead abatement and recoating are performed on a structure to bring it into compliance with federal, state, and local regulations regarding tower visibility requirements for air traffic. “Maintenance money is sometimes hard to obtain and secure for special projects like steel structure maintenance,” Holloman says.

As the building of the North American smart grid continues to gain momentum, however, it’s reasonable to expect that more dollars will be made available to build new structures to accommodate the restructuring of the electric power grid. “And in many cases, money to replace old structures is more readily available,” Holloman notes.

But some believe the tide may be turning, and more electric utility companies will start developing maintenance programs to repair and preserve their current inventory of steel transmission and distribution structures as it becomes more cost effective. The proper inspection and maintenance programs can pay dividends by extending structure life and increasing system reliability. Geographically, North America has a very diverse climate, which influences the type of inspections needed, and Holloman notes there are a lot of maintenance projects now underway in the Southeast and along the East Coast due to the climate and other environmental conditions being more corrosive.

“Now, some utility companies are waking up to the need for maintenance programs because state public utilities commissions and [the Department of] Homeland Security are urging them to improve their maintenance programs,” Hickcox says.

“Some state utility commissions are balking at rate increase requests from electric utilities, forcing the utility companies to consider maintenance programs as a higher priority,” Holloman adds.

NACE and IEEE Collaborate on Joint Standards

Recognizing the industry’s need for guidance in developing maintenance programs, enterprising members from NACE and IEEE requested a joint TG be formed to develop standards that target the needs of the electric power utility sector. The joint committee members wanted to provide a starting point for utility companies to develop their own inspection and repair programs for existing steel transmission, distribution, and substation structures.

“The [ideas for the joint standards] were generated in discussions within Technology Exchange Group (TEG) 368X that brought together the electric utility folks from IEEE and the corrosion folks from NACE,” says Conner. “The members of TEG 368X first met during CORROSION 2007 in Nashville, Tennessee, and the committee has been the idea source for most of the [joint NACE/IEEE power transmission and distribution] standards that have been published or are now under development.”

Members of the committee, which combines the working knowledge and expertise of industry professionals in asset management who provide guidance in inspection, assessment, and corrosion control for electric power utility structures, discussed the nature of above-grade and below-grade corrosion of steel transmission and distribution structures. It became apparent that each of these sections of the steel structures required guidance for addressing different issues and needed to be addressed separately. While the condition of the above-grade sections of steel transmission towers and distribution structures is relatively easy to visually inspect and assess, the buried or below-grade sections are often subject to a more corrosive environment and are not easily accessible for visual inspection. The committee’s efforts resulted in the publication of three joint NACE/IEEE standards.

These initial standards were developed as complementary companion standards and can be easily integrated into an existing or new maintenance program targeting the below-grade zones and the above-grade areas of steel structures. The third standard provides an assessment and data collection tool for below-grade structures.

Three Joint NACE/IEEE Standards Published

NACE SP0215-2015/IEEE Std. 18394 focuses on below-grade corrosion control and provides general coating repair guidelines for in-service carbon steel and galvanized steel electric transmission structures coated with polyurethanes, moisture cure urethane (MCU), coal tar, epoxy, coal tar epoxy, and cold-applied tape systems including petrolatum and polyethylene. The standard includes procedures for identifying structures that may be at higher risk for below-grade coating degradation; excavating and inspecting; assessing the level of corrosion attack and degradation risk to the structure’s existing coating system; prioritizing structures to be repaired; and applying repair coatings to the structure when required. In addition to these procedures, the standard includes five tables with information ranging from basic guidelines for determining corrosion risks and coating system condition assessments to guidelines for determining the suitability of select tape systems.

NACE SP0315-2015/IEEE Std. 18355 applies to the repair of above-grade atmospheric coatings and defines the atmospheric area of the structure to be coated. It provides guidance for assessing structures for atmospheric corrosion and the level of risk to the structure from degradation of the existing coating system and corrosion attack, and can serve as a resource for preparing specifications to achieve the successful coating of utility structures. Also included are three tables that provide example rating systems to assess coating systems, surface preparation methods for electric utility support structures, and a coating chart.

NACE SP0415/IEEE Std. 18952 provides guidance for implementing common inspection practices and technology on the below-grade areas of steel transmission towers, poles, and substation structures, including galvanized, self-weathering, painted mild steel, and other similar structures. The standard incorporates a section on data collection/prioritization and a graduated, three-tier field inspection system. It also includes access to an interactive spreadsheet that can be downloaded to electronic devices, customized, and used for data collection in the field. Before the publication of this standard, an industry practice to help electric utilities determine a prioritized listing of structures to be inspected or describe an inspection and assessment procedure to evaluate below-grade corrosion issues did not exist.

“The inspection and assessment standards are especially valuable, as a utility or owner now has a method to help prioritize structures that will need attention,” Conner says. “Prior to this, much of the approach to maintenance was done on a hit-or-miss basis. Critical areas could be easily overlooked, and often were discovered quite by chance.”

The Path Forward

The electric power industry still has some work ahead to fully implement maintenance programs across the North American electric power grid. Holloman reports that ~10 to 15% of utility companies in North America have some sort of steel inspection program in place, ~15 to 20% are thinking about it, and about 50% haven’t started the dialogue to make it happen. The rest are unsure of where to start and what return on investment can be expected. That’s when NACE can help.

NACE is committed to developing industry standards to provide guidance to utility companies in their quest to develop the most appropriate inspection and maintenance programs for their steel structures. Evidence of this continuing commitment can be found in the work of the joint TGs (NACE/IEEE TG 529 and TG 538) that are developing more standards for the electric power transmission and distribution industry. TG 529, “Atmospheric Above Grade Inspection and Assessment of Corrosion on Steel Electrical Transmission, Distribution, and Substation Structures,” is writing a new standard practice to address the atmospheric above-grade inspection and assessment of corrosion on steel electrical transmission, distribution, and substation structures as a companion to NACE SP0415-2015/IEEE Std. 1895. A proposed standard being developed by TG 538, “Inspection and Assessment of Below Grade and Ground line Corrosion on Weathering Steel on Electrical Transmission and Distribution Structures,” is intended to guide electric utilities when inspecting and assessing corrosion of weathering (ASTM A588) steel on in-service transmission, distribution, and substation structures.

“The partnering of NACE and IEEE is a perfect example of how NACE can provide a valuable, and often not well understood, resource to a wide variety of industries,” says Conner.

References:

1 E.R. Pierce, “Top 9 Things You Didn't Know About America's Power Grid,” Energy.gov, November 2014, http://energy.gov/articles/top-9-things-you-didnt-know-about-americas-power-grid (October 14, 2015).

2 NACE SP0415-2015/IEEE Std. 1895, “NACE/IEEE Joint Standard Practice for Below-Grade Inspection and Assessment of Corrosion on Steel Transmission, Distribution, and Substation Structures” (Houston, TX: NACE International, 2015).

3 S. Gerrity, “INFOGRAPHIC: Understanding the Grid,” U.S. Department of Energy, November 2014, http://www.energy.gov/articles/infographic-understanding-grid, (October, 14, 2015).

4 NACE SP0215-2015/IEEE Std. 1839, “NACE/IEEE Joint Standard Practice for Below-Grade Corrosion Control of Transmission, Distribution, and Substation Structures by Coating Repair Systems” (Houston, TX: NACE, 2015).

5 NACE SP0315-2015/IEEE Std. 1835, “NACE/IEEE Joint Standard Practice for Atmospheric (Above Grade) Corrosion Control of Existing Electric Transmission, Distribution, and Substation Structures by Coating Systems” (Houston, TX: NACE, 2015).