Corrosion poses a threat to all infrastructure through the degradation of structures such as buildings, roads, bridges, pipelines, and towers, and the economic impact of corrosion represents an annual cost of billions of dollars to the economy. It is important that owners and operators of high-value assets understand the cost implications of ignoring the effects of corrosion. There are many advantages of planning for corrosion control and mitigation. Two of the main ones are that the life of an asset is extended, making it more profitable; and the asset’s maintenance time and costs are reduced, which enables its increased utilization.

According to Justin Rigby, coatings consultant at Remedy Asset Protection (Melbourne, Victoria, Australia) and a NACE International CIP Level 3 Coatings Inspector, there are two main ways to protect an asset from corrosion. One is to alter the physical properties of a metal by using a technology such as cathodic protection to impress a current into a structure to minimize corrosion. The other is to physically isolate a structure from the environment by applying a protective coating. It is important that a protective coating project is carefully planned, he says. One thing to avoid is underestimating the technical complexity of a project, especially if the coating is to be applied to an existing structure and even more so if the site is in a remote location.

“A protective coating is not just paint. It is an engineered product that undergoes rigorous product development to provide specific properties that will protect a structure from its service environment,” says Rigby. “The most important considerations are assessment of the service environment and selection of the required coatings.”

There is a wide selection of coatings products available to the market, so it is essential that the appropriate coatings system is chosen. There is no single product that meets every coating situation, so a compromise may need to be made during the planning stages of a project.

According to Rigby, a good specification will reference AS/NZ 2312,1 categorize the service environment according to its corrosivity, and then nominate a coating system based on the desired design life of the coating. He recommends seeking advice from a competent colleague or external consultant when building a specification and selecting the most appropriate coating system. The major coatings manufacturers, including AkzoNobel, Altex, Dulux, Jotun, PPG, Sherwin-Williams, and Valspar, are also good sources for reputable advice.

Traditionally, coatings protect a structure by creating a physical barrier to the environment. Modern technology has developed active pigments that are being incorporated into primers to provide additional protection. Active anticorrosive pigments are added to primers that can give further protection for areas with coating damage in addition to their barrier effect. These pigments prevent corrosion of a metal substrate by building up permanently passive conditions at the metal surface and/or by a build-up of solid compounds that fill in the damaged area of the coating.

It is important to be flexible and adaptable when developing protective coating projects. “A protective coatings project, managed well, provides owners with great outcomes,” Rigby states. “However, when a protective coatings project goes wrong, it exposes the team to a range of problems that can make your head spin.” He recommends spending time with a consultant at the prestart stages of a project to help identify areas of risk. While this is an extra expense, it will ensure the project is successful and could protect a project manager's reputation for project delivery.

The TBS Group (Auckland, New Zealand) has more than 40 years of experience in all aspects of corrosion prevention, detection, and remediation. TBS has worked on a diverse range of projects, including New Zealand’s Auckland Harbour Bridge and heritage-listed structures such as the Makatote Viaduct. The company operates an abrasive blasting and painting facility in New Plymouth, New Zealand, which features two grit rooms, five paint shops, and a specialist thermal metal spraying facility.

NACE’s strategic partner, the Australasian Corrosion Association (ACA) (Kerrimuir, Victoria, Australia), works with companies such as TBS and academia to research all aspects of corrosion to provide an extensive knowledge base that supports best practices in corrosion management, which helps ensure that all impacts of corrosion are responsibly managed, the environment is protected, public safety is enhanced, and economies are improved.

Once a coatings project is underway, there are several aspects that need to be carefully managed. It is important to understand the competence of the applicator and also ensure the main contractor does not accept lower-quality materials that do not meet specifications. “Asset owners must understand that their 'whole of life' costs are not necessarily a priority for the main contractor when a new asset is built, and could be diametrically opposed,” says Graham Matthews, technical director of TBS. “The contractor may see an opportunity to save a few dollars by amending a specification and the structure may survive the guarantee period, but the resultant future maintenance costs are far higher.”

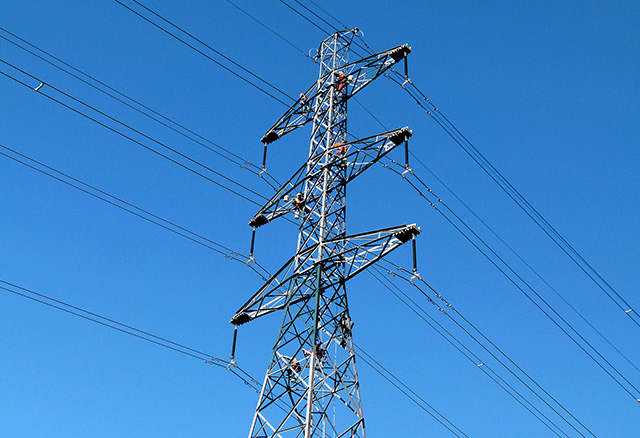

Additionally, the technicians chosen to apply a coating must have the appropriate skills. Obvious selection criteria are experience with the protective material and the equipment used to apply it to a structure. A less obvious criterion, especially for any sort of tower structure, is abseiling (rappelling) skills; technicians might have to be in a harness and suspended in mid-air, which requires a particular mix of physical and psychological attributes.

Additionally, the technicians chosen to apply a coating must have the appropriate skills. Obvious selection criteria are experience with the protective material and the equipment used to apply it to a structure. A less obvious criterion, especially for any sort of tower structure, is abseiling (rappelling) skills; technicians might have to be in a harness and suspended in mid-air, which requires a particular mix of physical and psychological attributes.

One vital aspect of coatings projects is to have compliance certification that the job complies with all the appropriate legislation, regulations, and standards. There are two ways to achieve this—either to pay for third-party inspection or engage a contracting firm that has a number of staff members who are either NACE- or ACA-certified Coatings Inspectors. This will provide peace of mind to customers that quality is “built in” throughout project planning and execution.

There is an old adage in the carpentry and construction trade, “Measure twice; cut once.” A variation of this adage applies equally to the corrosion protection industry: “Plan it right and do it once.” The cost to coat a structure with an appropriate and effective protective material varies depending on whether it is applied in a workshop or on site. “The average cost to apply a three-coat system in a workshop may be around $80 per square meter,” says Matthews. “On site, this might increase to $300 per square meter or higher. Do not scrimp on the coatings specification or the quality verification, as these could be some of the best dollars spent on a project.”

There are variations to these figures. For example, the repainting—with lead paint—of the complex latticework of the Makatote Viaduct cost ~NZD $1,000/m2. The NZD $12 million refurbishment of the heritage-listed structure required scaffolds up to 80-m high, an on-site team of 30 people, and deployment of more than NZD $4 million worth of specialized plant and equipment. In comparison, the touch-up repairs to the iconic Auckland Harbour Bridge using lead-free paint only cost NZD $150/m2 since the bridge was designed with good access systems.

There are many standards relating to the application of protective surface coatings, but sometimes compromises may need to be made. When planning a protective coating project, it is important to take factors such as the geography, access to the structure, and climate into account, all of which impact the cost of the project.

There are many standards relating to the application of protective surface coatings, but sometimes compromises may need to be made. When planning a protective coating project, it is important to take factors such as the geography, access to the structure, and climate into account, all of which impact the cost of the project.

If a structure to be protected is in a remote location, it will be necessary to select the most cost-effective means of transporting materials and personnel to the site. Additionally, remote sites may be exposed to climatic extremes that impact coating application. For example, monsoon rains in tropical regions would make it difficult to spray a coating onto any type of structure.

The health and safety analysis of a project must look at how to effectively protect a structure and address any environmental considerations. It must also consider how to properly apply the coating to minimize its effects on the surrounding areas as well as protect the technician who might be working in a harness tethered meters above the ground. “When you get to site, there may be odd arrangements of pylons and bracing, making it difficult for a technician to access all parts of a structure to apply a coating,” adds Rigby.

There are relatively few reasons why protective coatings projects are unsuccessful; however, planners often do not fully comprehend the complexity of many coatings projects and, as a consequence, fail to invest the time and resources to manage them effectively, which results in substantial cost implications when things go wrong. A lack of detailed design information for a structure sometimes means there is poor selection of structural materials, such as dissimilar metals, which means the coating options are restricted (i.e., a coating for one metal is most likely inappropriate for the other).

Throughout the year, the ACA conducts educational activities such as seminars and training courses across Australia and New Zealand to inform and guide organizations and practitioners about corrosion topics. Corrosion specialists certified by NACE, the ACA, and other organizations have an understanding of corrosion causes, and the experience with solutions that allow them to recommend mechanisms and procedures to consultants and asset owners.

Source: Australasian Corrosion Association, corrosion.com.au

Reference

- AS/NZS 2312.1:2014, “Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings—Paint coatings" (Sydney, NSW, Australia: Standards Australia, 2014).