Materials Performance Roundtable Q & A

The iconic San Francisco-Oakland Bay Bridge (Bay Bridge) is an 8.4 mile (13.5 km) structure that connects Oakland and San Francisco, California. In October 1989, the Loma Prieta earthquake caused the upper deck of the bridge’s East Span to collapse, which resulted in a major construction project that began in 2002 to replace it. Beneath the new East Span road decks at the eastern end of the bridge’s Self-Anchored Suspension (SAS) span, there are seismic devices known as bearings and shear keys. The bearings allow the road decks to move slightly during an earthquake, while the shear keys prevent the decks from moving too much.

On March 1, 2013, workers began tensioning the 96 ASTM A354 Grade BD rods fabricated in 2008 for two of the East Span’s four shear keys. Shortly after that, it was discovered that 32 of the 96 rods had fractured. Engineers and metallurgists determined the bolts had cracked due to hydrogen embrittlement (HE), which occurs when excess hydrogen, a susceptible material, and tension are present.

Last fall, Caltrans bridge inspectors found that more than 400 high-strength steel rods imbedded in the SAS tower’s foundation were not sealed properly, which failed to protect them from the environment. The anchor rods became the focus of attention when Caltrans discovered they were ineffectively grouted by the contractor and sitting in standing water. The threads of one rod stripped through its bottom nut and failed, prompting a thorough investigation of all the rods.

A Materials Performance (MP) article in November 20141 described the corrosion-related events associated with the new East Span of the San Francisco-Oakland Bay Bridge, which included a discussion on the shear key anchor rods that failed after tensioning. MP then published an article in the June 2015 issue2 that presented an alternate view of the failure mechanism.

To expand on these articles, MP asked several NACE International members and others to comment on HE and its effect on the bridge’s high-strength steel rods, as well as other corrosion issues that could affect the bridge.

Panelists are Yun Chung, retired materials engineering specialist; Sheldon W. Dean, Jr., FNACE, president of Dean Corrosion Technology, Inc.; Jeffrey A. Gorman, consulting engineer at Dominion Engineering, Inc.; Russell D. Kane, materials and corrosion consultant at iCorrosion, LLC; Patrick P. Pizzo, Professor Emeritus, San Jose State University; and Herbert E. Townsend, FNACE, metallurgical engineer at Townsend Corrosion Consultants, Inc. (See their biographies in the sidebar, “Meet the Panelists.”)

Question 1: What is the basis for estimates of the threshold stress for anchor bolt susceptibility to environmental hydrogen embrittlement (EHE), and what is the relationship of this threshold stress to hardness?

Dean: It is well known that the susceptibility to hydrogen embrittlement (HE) is related to the hardness of steels. However, the hardness is only one of several variables that are important in determining the susceptibility of steel to EHE. The environment is crucial. In the absence of aggressive components such as hydrogen sulfide (H2S), the hydrogen overvoltage is probably the most important environmental variable. This variable is discussed further in my answer to Question 9.

In addition, the composition of the steel and its heat-treatment history are important. In particular, the sulfur content of the steel is a key variable affecting EHE susceptibility. In the case of the rods used in the Bay Bridge, the basis that was determined for these items was the experimental program carried out using full size rod specimens in a 3.5% sodium chloride (NaCl) solution. This work proved that the threshold stress was above 0.75 of the minimum tensile strength for the rod alloy (AISI 4140).

Chung: For high-strength steels, σth-EHE, the threshold stress for EHE may be calculated from KIEHE, the stress intensity factor for EHE. The lower the KIEHE or σth-EHE, the higher the susceptibility to EHE. σth-EHE would decrease with increasing hardness. For a production lot of ASTM A354 Grade BD rods, hardness could serve as an index of EHE susceptibility. The threshold stress, σth-HE, for hydrogen embrittlement (HE), both internal HE (IHE) and environmental HE (EHE), is as follows. Read More

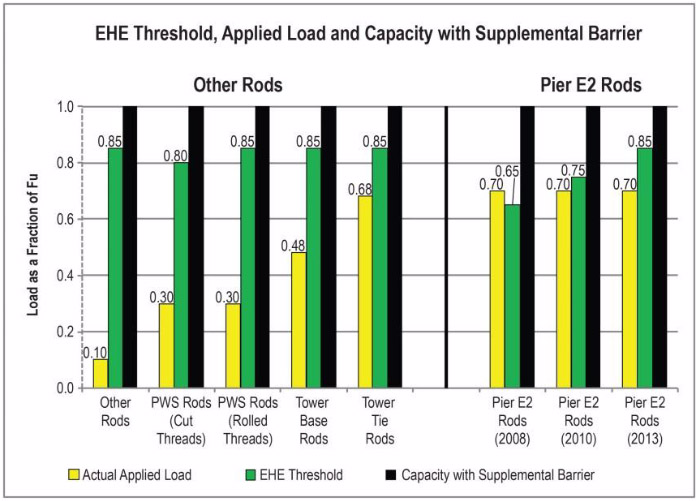

Gorman: The loads at which full size anchor rods failed due to HE were measured in Test IV.3 These loads, reported as fractions of Fu, the minimum specified tensile strength, can be converted to stress by multiplying by the minimum specified tensile strength of 140 ksi (965 MPa). The load at which the 2008 anchor rods failed in Test IV was 0.7 Fu, equivalent to a stress of 98 ksi (676 MPa). The minimum load at which any of the other rods failed in Test IV was 0.8 Fu, or a stress of 112 ksi (772 MPa).

The stresses and equivalent loads at which samples of the rod materials cracked due to HE were also measured in Test V3 using small Charpy-size specimens. The Test V results corroborated the Test IV results. In addition, since many more specimens were tested in Test V, they permitted correlations to be developed for several sets of the rods between hardness and the stress required for occurrence of HE. These correlations showed the stress required for the occurrence of HE decreased as hardness increased, and that it also decreased as the potential established by the zinc coating became more negative. Read More

Kane: From my independent analysis of this situation, the basis for assessing threshold stress vs. EHE for high-strength steels of the type found in the Bay Bridge rods (ASTM A354 Grade BD with nominally C-1.0Cr-0.25Mo steel compositions) comes primarily from three sources: (1) KEHE vs. hardness in the published literature as represented by the Townsend paper4 developed for nominal C-Cr-Mo steel compositions per UNS G41400 (C-1.0Cr-0.25Mo steel) using precracked specimens; (2) EHE data developed by the bridge team specific to the bridge’s high-strength rods (defined by ASTM A354 Grade BD as similar to UNS G41400 through full-scale rod tests and incremental step-loaded tests3): (a) full-scale rod tests and (b) precracked incremental step-loaded tests.; and (3) personal experience spanning 40 years related to the use of high-strength steels (mostly UNS G41400-300 and UNS G43400) vs. EHE for oilfield casing and tubing and offshore applications involving bolting. Based on steels of generally similar steel composition (UNS G41400) and similar metallurgical processing (austenitizing followed by quenching and tempering), susceptibility to EHE has been shown to increase (producing a decrease in threshold stress or stress intensity for EHE) with increasing material hardness. Read More

Pizzo: The Raymond Test V and the Gorman Test VI in the Caltrans study3 confirm the earlier published results of Townsend4 for precracked specimens. The critical stress intensity factor for HE/stress corrosion cracking (SCC) in the presence of a corrosive environment for 4140 steel, Zn-coated or not, occurs in the hardness range from about 32 to 34 HRC [on the Rockwell hardness scale]. The surface hardness of most of the A354 BD rods and bolts in the SAS Bay Bridge structure are greater than 34 HRC.

It is the representative microstructure/hardness adjacent to the cold-rolled threads that will determine the susceptibility of the steel to HE/SCC, assuming the hardness at the R/2 cross-sectional position of the rods is appropriate for only the higher hardenable steel grades or the smaller diameter rods/bolts. The hardness data reported in the various Caltrans reports3, 5-8 demonstrate that the near-thread-root hardness is generally higher than the hardness at position R/2 for bolts sized in the 3 to 4 in (76 to 102 mm) diameter range. Read More

Townsend: EHE thresholds were determined by use of slowly increasing step-load tests in 3.5% sodium chloride solution, based on the work I published in 1975.4 These tests were conducted on full-size anchor rods representing various locations on the bridge. They provided reliable, conservative values of the EHE threshold. The results clearly show that the preload tensions of all remaining rods are safely below the EHE thresholds determined in our tests, as summarized in Figure 1. In particular, the 0.48 Fu preload tension in the tower-base rods is well below the EHE threshold of 0.85 Fu as determined by our tests; it can be concluded that these rods will not fail by EHE in the near term. This conclusion is in agreement with the real-world performance of the tower-base rods, some of which have been immersed in water for several years at 0.48 Fu without failure. Of course, measures are needed to remove the water and protect the rods from future exposure to water in order to prevent corrosion for the life of the bridge. Read More

Question 2: Is there a distribution of EHE susceptibility (bell curve or other) that corresponds to the distribution of hardness values?

Pizzo: The Fu minimum allowable ultimate tensile strength for this project is 140 ksi. This correlates to a hardness value between 36 to 37 HRC. This lies in the range of HE/SCC susceptibility. In a technical review report,6 the authors of this independent review suggest the use of a different type of high-strength steel, ASTM F1554, as a more common and appropriate selection for anchor bolts due to better ductility, better ability to be bent, and greater suitability for galvanizing. It is a lower-strength option.

However, the December 2014 Caltrans report5 states, “While the TBPOC has concluded that all the remaining A354 BD rods are safe for continued use, the designer of the bridge also has indicated that the design redundancy and a factor of safety of 1.4 mean that the full complement of remaining E2 rods is not required to meet design requirements during an earthquake. In fact, at each shear key and bearing location, as many as 30% of the rods could fail and the remaining fastening capacity would be sufficient to resist expected seismic loads.” Perhaps in retrospect the lower strength, ASTM F1554 bolts would have been a better choice for the SAS, as the HE/SCC susceptibility would be a non-issue. Future projects of this nature should consider this viewpoint.

Townsend: It is reasonable to expect a distribution of hardness values among any group of rods made from quenched-and-tempered low-alloy steel. Based on hardness measurements made in the laboratory and in the field on almost every rod on the bridge, the actual variation in hardness among rods is remarkably small. Our tests show that EHE thresholds of rods with similar average hardness are affected by other factors, which include (1) surface hardness (M-shape profiles are beneficial); (2) thread-forming method (rolled threads are better than cut threads); (3) Charpy impact toughness (higher Charpy V-notch [CVN] is better); and (4) electrode potential of the hot-dip galvanized (HDG) coating (less active potentials resulting from higher iron contents lead to higher EHE thresholds).

Gorman: The answer to the above question is “yes” as shown by a figure in my response to the previous question. It shows how the threshold stress for occurrence of HE in an aerated near neutral 3.5% NaCl solution with an applied potential of -1.106 V vs. a saturated calomel electrode (SCE) varied for the 2010 and 2006 anchor rods. It needs to be kept in mind that this curve can vary from one group of rods to another, depending on factors such as root radius, residual stresses at the root of the thread, etc., as discussed in the response to the previous question.

Dean: In order to answer this question it is necessary to define EHE susceptibility in quantitative terms. Let us define this susceptibility as the threshold stress that will cause an intergranular type of crack progression (i.e., cracking along prior austenite grain boundaries) within a defined time period in a fixed environment, and further that the threshold is the highest stress level that can be sustained without crack formation. In this case, with a homogeneous lot of steel, the relationship between hardness and threshold stress will show a monotonic relationship with the threshold stress decreasing as the hardness increases.

However, if one examines the process in more detail, there does not appear to be a direct correlation between the hardness and the crack development. Local hard spots in the steel are not more likely to crack than adjacent areas. For example, specimens with rolled threads did not suffer EHE cracking while similar specimens with cut threads did. In this case, the thread rolling process probably introduced localized internal compressive stresses and upset the grain structure of the steel, which reduced the susceptibility to EHE. However, the hardness of the rolled threads was higher than cut threads so hardness is not the controlling variable. From a statistical point of view, this would suggest a large standard deviation between hardness and EHE threshold, because hardness in not the controlling variable.

Kane: Yes. Both the original Townsend data4 and the best fit line from Raymond tests in the Bay Bridge study3 show graphically that the susceptibility to EHE increases (KIEHE values decrease) with increasing hardness within the hardness range allowable by ASTM A354 Grade BD (HRC 31 to 38) and beyond. The Raymond tests show that EHE failures are predicted at much lower Fu loadings than those occurring in the original field failures and the full-scale EHE tests. They are down in the range of Fu loading to which many of the Bay Bridge rods are exposed.

An interesting comparison can be made between allowable hardness range in ASTM A354 Grade BD (31 to 38 HRC) and that provided in API RP 17A9 (ISO 13628-110) for low-alloy steel fasteners (HRC 32 maximum) that are subject to exposure to seawater under cathodic protection (similar to Zn coating). The combination of (a) the recommendation in the A354 BD specimens to avoid Zn-coating with these rods, (b) the long-established trends in the Townsend study, and (c) vastly lower hardness limits as defined for seawater-exposed bolting in the API standard all show that there should have been no surprise that high-strength steel bolts with Zn coating would lead to a rod failure scenario in the Bay Bridge. Read More

Chung: In theory, yes. In practice, however, it would be difficult to establish a σth-EHE bell curve like a hardness bell curve. While a hardness test is simple to perform, a σth-EHE test can be rather complicated, and there is no conversion equation between the two. For example, Caltrans claimed to have determined 0.65 Fu and 0.75 Fu as σth-EHE for the 2008 A354 BD rods and 2010 A354 BD rods, respectively, from Test IV.3 The 0.65 Fu, however, cannot be σth-EHE for the entire lot of 2008 A354 BD rods because not all of them failed subsequent to pretensioning to 0.70 Fu. The 0.75 Fu cannot be σth-EHE for the 2010 A354 BD rods because it was determined from only one rod with 36 to 37 HRC. The 0.75 Fu cannot represent the 2010 A354 BD rods with hardness higher than 37 HRC. Therefore, Caltrans was wrong to state that the 2010 A354 BD rods now in service are safe from EHE failures because they have been pretensioned to 0.70 Fu. Read More

Question 3: What is the safety factor for the hardest anchor bolts?

Dean: Safety factors are usually defined as the ratio of the tensile strength to the applied stress. In the case of the anchor rods used for the tower, this ratio is about 2.1. This ratio is based not on the hardest rod, but the minimum tensile strength for the specified metal. For the hardest anchor rod, the ratio would be greater, probably around 2.4. However, it should be noted that the concept of a safety factor for these rods is quite different from what would be used for a pressure vessel or structural beam. These rods are intended to be effective during an earthquake of a predetermined magnitude. They are not required for the normal operation of the bridge. Because the frequency of earthquakes reaching the specified magnitude is one in 1,500 years, the probability that the rods would ever be challenged to their required stress level is very low, and that stress level is below the minimum tensile strength of the rods. As a consequence, the safety factor is very conservative in spite of being lower than the values accepted for other types of service.

Townsend: Factors of safety for each group of rods can be calculated by comparing the heights of the bars in Figure 1. For example, the tower-base anchor rods are loaded to 0.48 Fu, and their EHE threshold is greater than 0.85 Fu. This indicates a safety factor of greater than 1.8 for rods exposed to water, and greater than 2.1 for rods that are dry. These values would not be substantially affected by the observed small variations in average hardness.

Kane: If you believe that the original Townsend data4 and the data from the Raymond tests in the Bay Bridge study3 are credible (which I do) and believe that there are potential methodology issues with the full-scale rod EHE test (which I do), there is little or no safety factor for the hardest rods per the ASTM A354 Grade BD specification or the highest loaded rods, particularly when put into service with a Zn coating. The range of Fu loadings in many of the Bay Bridge rods are precisely in the EHE threshold range (0.2 to 0.6 Fu) and too close for comfort when recommending a 150-year design life for the bridge. Chung has looked at test scatter and its impact on apparent safety factors on the bridge rods. I will leave that topic to him to address.

Chung: A safety factor for the A354 BD rods on the Bay Bridge SAS span may not be determined. This is because the σth-EHE data from Test IV3 are invalid. The safety factor for the “the hardest anchor bolts” could be less than one, which is unacceptable. Caltrans (and its bolt consultants) tried to establish σth-EHE by subjecting one or two full-size rod specimens to steploading cycles in a salt water solution. They also tried to use data from small specimen (CVN-specimen size) tests, Test V3 (the Raymond Test), to justify the data from full-size specimens in Test IV3 (the Townsend Test).

Philosophically, this scheme is backward. Small specimen data are not used to verify full-size specimen data. There are always some problems in extending small specimen data to a full-size rod because of variations in mechanical properties across the rod diameter. Either way, it would be difficult to establish σth-EHE that can guarantee, with a reasonable safety factor (such as 1.3), that all A354 BD rods on the Bay Bridge SAS span are safe from EHE failures. There is another reason why Test V may not be used to validate Test IV. There are no ASTM test methods for determining σth-EHE directly from a specimen, small or large. Read More

Gorman: This question is difficult to address since the actual environments to which the anchor rods will be exposed are not well defined and can vary between different sets of rods and over time. For the simplistic case, where the rods are assumed to be exposed to an aerated 3.5% NaCl solution, the tests indicate that the 2010 set of rods failed at a minimum load of 0.80 Fu, representing a margin of 0.1 Fu above the applied load of 0.7 Fu. However, analyses considering the distribution of hardness and potential developed by the zinc coating indicate that a few of the 2010 rods could fail in this environment at an applied load of 0.7 Fu. An additional consideration, as discussed in the response to Question 1, is that environments more severe than the test environment of aerated 3.5% NaCl could develop, especially for rods with their lower ends embedded in concrete structures, such as the 2008 rods that failed in 2013, and the tower base anchor rods that are currently being investigated.

The main conclusion regarding safety factors is the only approach that can reliably produce high safety factors against HE is to provide robust corrosion protection measures that ensure that the rods are kept dry (i.e., are protected against being exposed to environments that can produce HE). An additional observation is that the rods that have highest hardness at the root of the thread are those with rolled threads; because of the compressive residual stresses at the root of the threads, these rods have high resistance to HE.

Question 4: Did the additional stresses applied during attempts to achieve tower verticality meet or exceed that safety factor?

Gorman: It is understood that the loads applied to achieve tower verticality increased the total load by about 0.05 Fu. Experience to date is that the tower base anchor rods have not experienced HE at their applied loads of 0.37 and 0.48 Fu despite exposure of some of them to inward-leaking seawater, nor did they experience HE during the period when the load was increased on some of the rods by the 0.05 Fu increase applied for reasons of tower verticality. The only rod that might have experienced HE is Rod 3, which experienced thread stripping that apparently led to application of non-axisymmetric loads and increased stresses that might have caused HE. Further metallurgical examinations are required to determine if the rod actually did fail due to HE.11 Since the rods without stripped threads have not failed due to HE, it is

concluded that the increased loads applied during the tower vertical straightening operation did not use up the safety factor.

Townsend: Safety factors were not exceeded as a result of tower alignment. As design engineers for this bridge explain, the tower was erected to a close vertical tolerance. The top of the tower was temporarily pulled back ~500 mm during construction. This pull back was necessary to balance the asymmetric weight of free-hanging strands before the load was transferred from the supporting falsework to the cable. Peak stresses on tower anchor rods due to tower pull back were evaluated and found to be approximately 0.50 Fu for the 3-in diameter rods. This value is only slightly above the design pretension of 0.48 Fu, so it is clear that any effect on the factor of safety is negligible. Read More

Kane: This is a very likely scenario. As shown Figure 1.3-8 from the Bay Bridge Report,3 the main three variables in EHE are (1) adequate source of hydrogen, in this case from corrosion of the Zn coating, (2) sufficient tensile stresses, and (3) adequate material susceptibility to EHE. A fourth variable often omitted in this analysis is the parameter of time, as in the time needed to reach a critical level of internal hydrogen over a critical volume of material inside the steel, and the time to initiate an EHE crack prior to the onset of fast fracture by EHE. This is precisely why the results of the previous Townsend work and the current Raymond work should be weighed more heavily than the full-scale rod tests. By their inherent small cross-section and precrack design, they overcome the barriers to EHE initiation and the vagaries of installation and actual in-service variables. Read More

Chung: Caltrans pulled the tower to one side to counteract the unbalanced loading after the load transfer of the traffic decks. Caltrans released no details on how the tower base anchor rods were pretensioned after the load transfer. Therefore, only Caltrans can answer this question. Read More

Dean: Not that I am aware.

Question 5: Is it critical for bolt galvanizing to remain intact for long-term corrosion protection, and is it reasonable to expect galvanizing to remain intact for the 150-year design life?

Kane: Zn coatings do have a finite life that varies depending on the severity of the service environment, which generally increases with the amount of moisture, salt, and other contaminants; service temperature; and scenarios involving damaged coatings and wet-dry conditions. The harsh reality is that with the range of hardness in these bolts (even if HRC 38 is taken as a maximum value), EHE can still be a problem in some applications even without a Zn coating. It would be a good engineering decision on the Bay Bridge project to determine the

maximum possible service life of Zn coatings under various service conditions and also address the impact of steel corrosion once the Zn coating has been exhausted.

Dean: The galvanized coating is one of several measures that were applied to protect the rods. Its primary function was to provide protection in the event of a failure that exposed the rods to water. However, it is not a long-term measure for the protection against the damage that water exposure would cause. In the long term, the only solution is to prevent water from continuously contacting the rods. The galvanizing is effective in short- to moderate-term exposures (i.e., up to 5 to 10 years of water exposure). As long as water is kept away from the rods, the galvanizing will remain intact.

Gorman: There are two parts to my response. One, if the bolts are kept dry, the condition of the galvanizing will have no effect on HE or SCC since both require moisture to be present on the rod’s metallic surface. Two, if the bolts are allowed to become wet, then the condition of the zinc galvanized layer would be a critical factor. In this regard, zinc coatings exposed to marine atmospheres or to seawater generally have life spans of 20 to 50 years. With exposure to corrosive conditions, the zinc coating will eventually lose its protective capabilities such that, even if the load is below the value that can cause HE, general corrosion of the steel could eventually lead to failure of the rod. In addition, as the zinc coating coverage of the steel is reduced, its ability to prevent pitting and possibly active path SCC would be reduced, and the rod might fail due to SCC.12 This further demonstrates the importance of corrosion protection to achieve the 150-year life.

Pizzo: Caltrans has stated the following position regarding protective actions that have been taken on the rods (including the use of grease and paint), especially at the critical threaded areas, “... the corrosion protection measure being used at the SAS will ensure a long, failure-free life for the A354 BD rods.” Recent events such as the failed rod reported in June 2015,7 and the evidence of microcracking in the root of the cold-rolled threads require a reevaluation of this position. It is simply not probable that the environmental- and humidity-control measures can be sustained for the 150-year design life of the SAS. One can guard against general corrosion with protective coatings and grease; it is another matter to try to protect a coastal structure from HE/SCC using these methods. There is no substantiation for the conclusion that “these hydrogen embrittlement susceptible ASTM A354 rods will be fine in the 150 year life of the bridge as it is based on the assumption that the metallic surfaces will be protected from sea water exposure.” Caltrans could not assure this protection in the first year and one-half of the life of the bridge; how can they rely on this assumption for 150 years?

Chung: It would be wrong for Caltrans to state the A354 BD rods are “safe against environmentally induced hydrogen embrittlement as long as the galvanized coating remains intact.” First, the zinc HDG coating cannot protect A354 BD rods from EHE failures whether

intact or not if the steel is susceptible to HE. Its effects on EHE are about the same regardless whether the coating is macroscopically intact or not. Second, the zinc coating cannot remain intact during handling, installing, and pretensioning of A354 BD rods. It is not reasonable to expect a HDG zinc coating to last 150 years without a maintenance coating on the Bay Bridge SAS span. Some A354 BD rods on the SAS span can use a maintenance coating already. Read More

Townsend: It is not reasonable to expect that a galvanized coating will endure for 150 years under wet conditions. To ensure a 150-year life, the rods must be protected against corrosion—both general and pitting corrosion.

Question 6: Is it possible to apply proper maintenance measures (grout, grease, and paint) for anchor bolts that are submerged in water intrusions from the bay?

Chung: No, it is not possible. Painting, particularly over HDG threads, can never be regarded as a complete moisture barrier system. It is bound to deteriorate, exposing the HDG zinc coating and the steel substrate to rust due to moisture condensates from the atmosphere. The BD rods will eventually be charged with hydrogen from corrosion and will fail due to EHE if they are susceptible to EHE to begin with. Read More

Pizzo: May 2015 water tests indicate bay water intrusion in various locations throughout the bridge. Bay water is sufficient to meet the environmental requirement for SCC. In the MP article,1 water analysis data are presented in Table 2. This represents one sample and reflects chemistry after five years of possible immersion pretensioning, rod failure, and subsequent rod removal. Nevertheless, it suggests a legitimate concern: the effect of high-pH water on SCC of galvanized A354 BD bolts and rods. In the technical review report,6 the authors state that under some conditions the galvanized coating could become reactive with its environment and produce hydrogen as a result. This is true in alkaline environments such as those that may develop in cement-containing structures where moisture is a factor. This is why galvanized prestressing strands are not used in contact with cement grout in current U.S. practice. Research to evaluate the rate of absorption of hydrogen into galvanized and bare 4140 and 4340 coupons as a function of alkaline exposures is suggested to gain a better understanding of the hydrogen absorption behavior. Read More

Townsend: Because the tower rods are loaded well below the EHE threshold, there is no near-term concern about EHE. However, to ensure long-term integrity of the rods, it is essential that measures be taken to avoid corrosion associated with long-term exposure to water. As of this writing, several methods are being evaluated for this purpose, including grease and grout. It is understood that one or more of these methods will be evaluated in full-scale mockup tests prior to implementation on the bridge.

Kane: The answer to this question comes from both personal experiences with bathtub caulk, plumbing, driveway or foundation repairs, and from complex industrial systems, and even the first space shuttle disaster. Sealing and/or dehydration systems are hard to implement in dynamic structures in locations that are remote or not easily prepared or later inspected, and particularly when implemented as a retrofit where residual moisture is hard to remove.

In this case, the bridge has shown to have many sources of moisture already present: internal condensation, windblown moisture and salt spray, and seawater intrusion. The tasks of moisture removal (macro-dehydration), drying of the internals of the structure and crevices, removal of salt water ingress and resultant salt contamination, hydroscopic salt residue, sealing, barrier to or displacement of future internal moisture, and proactive future monitoring and remedial actions are daunting tasks that all come with the need for major long-term attention, monitoring, and funding. My answer is no. It would be naïve to think that long-term corrosion protection can be implemented at this point or in the future.

Dean: Yes. A grout system that is properly formulated and applied such that it neither shrinks nor cracks should provide adequate protection from water intrusion. Such water intrusion can only occur through cracks in the concrete at the bottom of the platform where the rods ends are located. The grout is contained in steel sleeves that would prevent any water access from the side. The sleeves also would protect the grout from stresses and defects in the concrete. The grout would keep bay water out of the sleeves and maintain a noncorrosive environment around the rods. Grease application has been used in cable systems successfully. However, there are several issues with grease that must be addressed in order to have the system be effective. Read More

Gorman: The answer to this question is that proper corrosion protective measures can protect the rods from contact with seawater and thus prevent occurrence of HE, SCC, and general corrosion. A good example that demonstrates this is experience at the Hood Canal Floating Bridge,13 where corrosion protection measures involving the use of grease and paint have prevented HE and SCC despite the rods being exposed to a much more aggressive marine atmosphere than present at the Bay Bridge (except for the lower ends of the rods embedded in concrete structures.)

Providing robust corrosion protection measures for the lower end of the tower base anchor rods is under investigation. It appears that the lower ends of some fraction of these rods are currently exposed to inward-leaking water from the bay. While this has not led to HE or SCC of rods that have not experienced thread stripping, this exposure to bay water is considered undesirable and could eventually lead to consumption of all of the zinc and severe general corrosion of the steel. Since this location is below the water level of the bay, providing robust protection against

contact with the bay water will require careful design and qualification, which is currently in the planning process.

Question 7: What is the significance of the microcracks that were discovered in all of the recently examined bolts?

Townsend: HDG coatings on the test rods were found to generally consist of brittle iron-zinc intermetallic compounds. When subjected to tensile stress, these coatings crack, particularly at regions of highest localized stress such as at thread roots. Depending on such factors as the magnitude of the stress and the toughness of the steel, some of these cracks may extend into the steel substrate for a very short distance to form microcracks. Such microcracks were present on the rods in our EHE tests, and so the EHE thresholds that were measured already take account of the effects of these cracks.

Although the crack in a galvanized coating can be no greater than the thickness of the coating itself, typically about 0.005 in (0.13 mm), the actual length of a crack at a thread root is equal to the sum of the coating thickness plus some fraction of the thread depth. The maximum possible crack length would be the coating thickness plus the entire thread depth. Read More

Pizzo: Caltrans reports the presence of microcracks in the roots of cold-rolled threads. One photomicrograph (Item 5d2 of the SAS tower anchor rod investigation update7) shows one such crack, ~12 µm in length. However, the crack clearly extends through the zinc surface coating, resulting in a longer effective crack size. Nucleation of a crack has occurred under sustained tensile loading of severely deformed and thus embrittled steel at the root of the rolled thread. A crevice has been created where environmental conditions may vary greatly from surface conditions. The crevice conditions will most certainly promote the entry of hydrogen into the steel, and the stress concentration at the tip of the crack will drive the accumulation of absorbed hydrogen. Assuming that the applied loads are sufficient, necessary conditions for time-dependent crack extension by the SCC mechanism will be met. Read More

Kane: As described in a recent newspaper article,14 a Caltrans representative indicated that microscopic cracks were found on at least two more Bay Bridge rods exposed to water. A third rod reportedly showed evidence of “fast fracture.” Apparently, there was also evidence of cross-threading and galling during the installation of the rods that adds another issue on top of that imposed by EHE. Cross-threading further adds to the intensity of local (and difficult to quantify) stresses in the threads, a region of the rod that already has stress concentrations from the thread profile, and that has been shown to be a preferred site for EHE. Read More

Dean: These cracks have no significance regarding the long-term performance of the rods. They are either the result of the thread cutting operation or the result of straining the brittle HDG coating beyond its ductility limit or both. They are present in all similar rods and were present in the test samples that were evaluated to determine the EHE thresholds. Any reduction in performance of the rods from these cracks has been accounted for in the threshold evaluation.

Chung: More details than those reported by Caltrans are needed to assess the significance of the microscopic cracks found in the thread roots of two tower base A354 BD rods, 136-2-3 and 150-1-2.15 The microscopic cracks include those that display intergranular indications. These cracks, less than 0.0055 in (0.14 mm) deep in the steel, were first found (inadvertently) while checking the zinc coating thickness under a microscope. If microscopic cracks are found consistently in the thread roots that experienced even transient loading, it would be significant because it could affect the understanding of EHE failures of HDG A354 BD rods. This is particularly so because most of the microscopic cracks in the steel have lined up with cracks in the zinc coating, and some in the steel are decidedly intergranular, at least in the initiation stage. Without a complete stress hysteresis of the specimens, it would be impractical to estimate their significance. Read More

Gorman: At present, there is no confirmed significant effect of the microcracks since there appear to have been no cases of HE or SCC of tower base rods that have not previously experienced thread stripping. From a hypothetical standpoint, it appears possible that the microcracks could reduce the threshold load for occurrence of HE based on the following considerations: (1) if microcracks are present at the root of the threads in a highly stressed area, such as at the first engaged thread at the lower nut, this could potentially reduce the load required to cause HE by about a factor of two; (2) the numbers of microcracks observed in the various anchor rods seems to be quite variable; and (3) the number of microcracks could also be influenced by the environment present at the highly stressed areas. Regardless of the above scenario, for the loads present on the tower base anchor rods (i.e., 0.47 Fu or less), the microcracks appear to have no effect, since the applied loads and stresses appear to be significantly below the failure threshold level. Read More

Question 8: Are there any long-term corrosion concerns that are not related to hydrogen?

Gorman: Yes, there are two long-term corrosion problems that are not related to rapid HE. The first concern is that general corrosion due to exposure to bay water or marine atmospheric environments can result in consumption of most or all of the zinc coating such that it can no longer protect the steel. This is likely to be followed by pitting and general corrosion of the steel until the cross-sectional area of the rod is no longer sufficient to carry the applied load. The second concern is that, after the zinc has been largely corroded away, pitting of the steel can occur and lead to active path SCC.12 As discussed in the responses to other questions, both of the above corrosion problems can be prevented in the same manner used to protect against HE (i.e., by applying robust corrosion protection measures that keep the metal surfaces of the rods dry).

Dean: Yes. If these rods are exposed to bay water for a long enough time, the galvanized coating will be corroded away, and then the steel will begin to corrode. If this should happen, the steel could corrode at rates between 2 to 5 mpy (50 to 125 µm/y). This would ultimately prove damaging to the strength of the rods. However, if microbiologically influenced corrosion (MIC) were to occur, the pitting that could result would prove very damaging to the rods in a much shorter period of time.

Chung: The Bay Bridge SAS span has a serious long-term corrosion problem: the corrosion damage to the individual steel wires of the suspension cable. In the two splay chambers and four other locations, the steel wires are protected from atmospheric corrosion by dehumidification only. The fatigue strength of the steel wire would continue to decrease if damaged by corrosion pits. The strand-socket junctures can fail due to corrosion fatigue unless the corrosion is stopped now. Caltrans has not released any data on the surface condition of the parallel wire strand (PWS) and individual wires in the four saddles of the SAS span. The weakest link that will determine the life of the Bay Bridge SAS span is not the ASTM A354 Grade BD anchor rods or the fatigue cracking of orthotropic steel traffic decks, it is the main suspension cable. Read More

Pizzo: High pH conditions developing in restricted regions of the rods/bolts can cause concentration cells to form; then even localized corrosion (and the concomitant metal loss) might become an issue.

Kane: There are several potential corrosion and noncorrosion issues that I’ve gleaned, which include flawed welds, misaligned deck sections, box sections with water in them, and botched grouting and sealing of existing elements of the bridge. I have not done an exhaustive study and do not have a complete list. I’d suggest contacting Caltrans or other the bridge specialists with a corrosion background for this list.

Townsend: Most certainly! As is the case with any steel structure exposed to a marine environment, ongoing inspection and maintenance will be needed throughout the life of the bridge to avoid the various corrosion issues that may occur. In the case of the Bay Bridge, particular attention should be given to critical load-bearing components, such as the main cables and the main-cable anchor rods.

Question 9: The June 2015 MP article postulated a failure mechanism involving exposure of the rods to high pH water in the top hats during the interval between grouting and pretensioning. Are there any comments on that possibility?

Chung: High-pH water in the top hats (bottom of the grout sleeves) can be an ancillary factor of EHE failures of the A354 BD rods; it cannot be the root cause of their EHE failures. High-pH water was not a common factor or the root cause of the EHE failures of all 32 A354 BD rod failures on Pier E2 of the SAS span. The top hat of Rod S2A6, one of the 32 failed A354 BD rods, had no water; and it was not exposed to high-pH water. Still, it was one of the first ones to fail. Clearly, it failed within several days of pretensioning as a consequence of its bottom end having absorbed enough hydrogen without being exposed to high-pH water. An exposure to high-pH water played a minor role in a majority of the 32 A354 BD rods that failed due to EHE. Read More

Townsend: In my opinion, such speculation is unnecessary. The postulated failure mechanism is based in part on the analysis of a sample of pH 13 water that was found in the duct of one of the 32 failed shear-key anchor rods on Pier E2. The composition of this sample is consistent with a mixture of rainwater and grout bleed. Because an intact HDG coating is a very effective barrier against hydrogen diffusion, it is very unlikely that sufficient hydrogen could have entered the steel during the one-month interval between grouting and tensioning. It is far more likely that EHE occurred after the rods were tensioned, causing cracking of the galvanized coating and allowing entry of hydrogen. Read More

Kane: Steels with hardness values in excess of HRC 30 can be susceptible to many forms of environmental cracking. This is why it is necessary in the design stage of a project (particularly where high-strength materials are involved) to obtain critical input from metallurgical/corrosion specialists with expertise in environmental cracking. Additionally, it is important to incorporate their recommendations and have critical tests performed in advance of purchase so that manufacturing specifications can be developed that assure a cracking-resistant design. In the case of the existing A354 BD rods, there was a complete lack of consideration for environmental cracking (and EHE specifically) and a lack of knowledge of the impact of material hardness and Zn-coating on the serviceability of these rods. Read More

Dean: First, it is important to understand the source of the high-pH water. In the manufacture of Portland cement, limestone is calcined along with a variety of other minerals. A portion of the limestone is converted to calcium oxide (CaO), which is then converted to calcium hydroxide [Ca(OH)2] (also known as slaked lime) by reaction with water.The slaked lime has limited solubility in water and a saturated solution of this compound has a pH of about 12.5. In order to obtain a higher pH, it is necessary to remove the calcium ions from the solution. Otherwise the hydroxyl ions will precipitate with the calcium. If compounds such as sodium or potassium sulfate are present in the cement, the calcium would precipitate out as calcium sulfate (CaSO4), but the hydroxyl ion concentration would remain the same. Developing a

higher pH requires that water be removed from the mixture. Read More

Gorman: This question literally applies to the 2008 rods (i.e., the shear key S1/S2 rods that experienced rapid failure after being tensioned in March 2008), since these are the only rods on the bridge with their lower ends in a top hat. However, similar environmental conditions can also develop at the bottom ends of the tower base anchor rods since they are dead ended; and there is evidence that water is getting to the lower nut area of these rods. For the tower base anchor rods, the higher pH that likely has occurred in the lower nut area could have lowered the threshold for occurrence of HE. However, it is apparent that the current load levels on the tower base anchor rods are below this reduced threshold since HE failures are not occurring as shown by ultrasonic testing and load tests despite the fact that bay water is reaching the lower nut area of some of the rods. In this regard, it is noted that Rod 3 may have suffered a HE failure; but this was apparently the result of its threads stripping, which resulted in development of high bending induced stresses; this scenario is not believed to apply to any of the other rods. Read More

References

- Y. Chung, “Corrosion on the New Eastern Span of the San Francisco-Oakland Bay Bridge,” MP 53, 11 (2014): p. 58.

- J.A. Gorman, D. Gross, T.S. Hall, S. Matty, S. Christoffersen, A. Cavendish-Tribe, R. Shulock, “San Francisco-Oakland Bay Bridge Anchor Rod Cracking Issues,” MP 54, 6 (2015): p. 52.

- B. Maroney, et al., “San Francisco-Oakland Bay Bridge, Self-Anchored Suspension Bridge, Evaluation of the ASTM A354 Grade BD Rods,” Caltrans, Sept. 30, 2014.

- H.E. Townsend, “Effects of Zinc Coatings on Stress Corrosion Cracking and Hydrogen Embrittlement of Low Alloy Steel,” Metallurgical Transaction 6A, April (1975): pp. 877-883.

- S. Heminger, M. Dougherty, A. Boutros, “Supplemental Report on the A354 Grade BD High-Strength Steel Rods on the New East Span of the San Francisco-Oakland Bay Bridge with Final Findings and Decisions,” Toll Bridge Program Oversight Committee (TBPOC) Report, December 30, 2014.

- J. Baker, R. DesRoches, R. Gilbert, Y. Hashash, R. Leon, S. Kumarascena, “SRC Technical Review of Design and Construction of New East Span of San Francisco-Oakland Bay Bridge,” July 31, 2014.

- S. Heminger, M. Dougherty, A. Boutros, “Supplemental Packet on the A354 Grade BD High-Strength Steel Rods on the New East Span of the San Francisco-Oakland Bay Bridge- SAS Tower Anchor Rod Investigation Update,” Toll Bridge Program Oversight Committee (TBPOC) Report, June 23, 2015.

- S. Heminger, M. Dougherty, A. Boutros, “Report on the A354 Grade BD High-Strength Steel Rods on the New East Span of the San Francisco-Oakland Bay Bridge with Final Findings and Decisions,” Toll Bridge Program Oversight Committee (TBPOC) Report, July 08, 2013.

- ANSI/API RP 17A-2010, “Design and Operation of Subsea Production Systems-General Requirements and Recommendations” (New York, NY: ANSI, 2010).

- ISO 13628-1:2005, "Petroleum and natural gas industries—Design and operation of subsea production systems—Part 1: General requirements and recommendations" (Geneva,Switzerland: ISO, 2005).

- M. Lisin, “Review of Tower Rod 3 Fractography Results, Lisin Metallurgical Services Job No. 524-15-003, Preliminary Report,” draft report, August 14, 2015.

- A. Asphahani, H. H. Uhlig, "Stress Corrosion Cracking of 4140 High Strength Steel in Aqueous Solutions,” J. Electrochem. Soc. 122, 2 (1975): pp. 174-179.

- R. Shulock, “Hood Canal Floating Bridge High Strength Anchor Bolts Example of Application of Greased and Sheathed Double Corrosion Protection Systems," Appendix E, draft report, BAMC, Sept 30, 2014.

- M. Cabanatuan, J. Van Derbeken, “Ominous new cracks found on Bay Bridge rods,” SFGate, June 24, 2015, http://www.sfgate.com/bayarea/article/Ominous-new-cracks-found-on-Bay-Bridge-rods-6345359.php (October 20, 2015).

- “Toll Bridge Program Oversight Committee, Meeting Materials,” TBPOC, Sept. 24, 2015, http://baybridgeinfo.org/sites/default/files/pdf/FinalTBPOCPacket-24Sep15%201_0_1.pdf(October 20, 2015).