In industries characterized by extreme operating environments that push materials, components, equipment, and tools to the edge of their design capabilities, companies are challenged to continually seek economically viable ways to improve performance, safety, and competitiveness. The oil and gas industry, for example, is faced with mitigating the impact of corrosion—which reduces the life of components such as drilling tools and pipeline valves—in ever-challenging environments such as sour service and ultra-deep water. Sour oil and gas containing hydrogen sulfide (H2S) can cause sulfide stress cracking, which inflicts significant damage on valves, pumps, and seals. Seawater, acidic media, carbon dioxide (CO2), and other aggressive media can cause a variety of corrosive attacks, including metal loss and pitting. Corrosive attacks can be especially quick and damaging when combined with abrasion or erosion, which removes the steel’s protective passive surface layers and can significantly accelerate corrosion.

Hard chrome plating (HCP) has been widely used for many years to successfully increase the life of tools and critical components; however, its manufacturing was banned in the European Union (EU) in September 2017 (unless authorized by the EU Commission), as it uses carcinogenic hexavalent chromium salts in its production. In the United States, the Occupational Safety and Health Administration is imposing increasingly tighter restrictions.

Existing HCP alternatives include high velocity oxy-fuel (HVOF) and physical vapor deposition (PVD) techniques, as well as emerging processes such as electroless-nickel composite plating and explosive bonding. Although successful in some applications, each has its limitations. HVOF coatings can create a very thick and durable layer, but cannot be applied to internal surfaces. They are rough and porous and often require post-coat grinding, which is not possible on intricate shapes. PVD coatings can produce an extremely hard layer with an accurately controlled thickness, but are very thin (typically <4 µm) and have limited abrasive/erosive resistance and load-bearing capacity. Various wet electroplating and electroless coatings are more suitable for internal surfaces and complex shaped parts, but have lower hardness than HCP and less wear resistance.

Extensive testing of chemical vapor deposition (CVD) tungsten carbide (WC) coatings developed by Hardide Coatings Limited (Oxfordshire, United Kingdom) has proven that low-temperature CVD coatings can be tough and provide a practical, technically, and commercially viable solution to HCP coatings that are capable of increasing component and tool life.

These CVD coatings belong to a family of nanostructured W/WC coatings. They are crystallized atom-by-atom from low-pressure gas media. Crystallization at an atomic level produces a uniform, pore-free coating because the highly mobile reaction products fill micropores and defects in the coating as it grows. The gas phase of the CVD process enables internal surfaces and complex designs to be coated, which allows this technique to coat “out of line-of-sight” surfaces and geometries where spray coatings cannot be used. Due to the deposition mechanism, CVD WC coatings have exceptionally low porosity and do not need to be sealed. The dispersed WC nanoparticles give the material enhanced hardness, which can be controlled and tailored to give a typical range of between 800 and 1,600 Vickers hardness (HV) for different coating types. The CVD coating can be produced in thicknesses ranging from 5 to 100 µm, and can match the thickness of HCP, thus simplifying the replacement process.

By varying the ratio between the thickness and properties of each individual layer, the overall coating characteristics can be adjusted to meet specific application requirements. The hardest CVD WC coating (3,000 to 3,500 HV), Type H, consists of pure WC, which is extremely hard and has limited thickness (5 to 12 µm) and satisfactory toughness. The multilayer CVD WC coating, Type M, includes layers of various hardness and exhibits good toughness. The most widely used type of CVD WC coating is Type T, which consists of WC nanoparticles dispersed in a tungsten matrix. This structure gives it a unique combination of properties: high hardness (from 1,100 HV to 1,600 HV) combined with excellent toughness for impact and crack resistance. The CVD WC coating developed to replace HCP, Type A, matches its hardness and thickness.

Both W and WC are highly chemical resistant and protect against mineral acids that include hydrochloric acid (HCl) and sulfuric acid (H2SO4). Additionally, the CVD process—unlike sprayed HVOF coatings—does not use cobalt, which can be affected by acid. As a result, the nonporous CVD WC coatings are resistant to many aggressive chemicals and can be used as an effective anticorrosion barrier for critical parts.

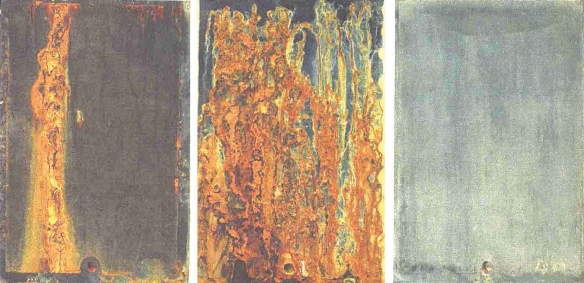

Several tests were run to confirm the CVD WC coatings’ performance. In accordance with ASTM B117,1 mild steel plates coated with HCP, HVOF, and CVD WC Type T coatings were subjected to a neutral salt spray. The HCP samples became very corroded after 288-h of exposure and were removed from test. After 480 h, the HVOF-coated samples showed heavy rust stains and the coating blistered due to intensive corrosion of the steel plate beneath. The CVD-coated samples showed light staining.

In accordance with the NACE TM01772 and ASTM G39,3 the CVD WC Type T coating was tested for sulfide stress cracking by Bodycote Materials Testing for resistance to aggressive media. One uncoated and three coated samples of 17-4 PH (UNS S17400) stainless steel (SS) and also coated 316 SS (UNS S31600) and Inconel 625 (UNS N06625) samples were tested in deformed conditions (with coating elongation up to 3,000 microstrain) in a 5% sodium chloride (NaCl)/5% acetic acid (CH3COOH) solution saturated with H2S.

During the test, the uncoated sample cracked completely across its 20-mm width and experienced extensive microcracking and pitting, while the CVD WC-coated substrates showed no microcracking, macrocracking, or degradation. This demonstrated that the coating can help extend the life of valves or pumps controlling sour oil and gas in both upstream and downstream applications.

To test galling resistance of the CVD WC coating, a Phoenix TE77 high-frequency reciprocating test rig was used. This test uses the reciprocating dry sliding movement of a cylinder on a flat plate with loads gradually increasing from 10 to 800 N (equivalent to contact pressure of 810.2 MPa). It monitors the coefficient of friction (CoF), where a value above 1.0 indicates severe galling. In comparison with a baseline control test using a SS pin, which was stopped due to sample seizure after reaching a 1.0 CoF value with a 65-N load, a CVD WC-coated pin was tested against a coated plate, and the dry CoF remained low, stabilizing at around 0.2. No galling was observed, even under the maximum load the test rig could produce.

To determine its resistance to acid, the CVD WC coating was tested for 113 h in 20% nitric acid (HNO3) alongside a WC/Co detonation coating. The CVD WC-coated sample turned a yellowish color due to slight surface oxidation. Its dimensions did not change and the weight loss was not measurable (less than 0.001 g). Its surface roughness remained at 0.10 µm roughness average (Ra), which indicated it had not been attacked.

In the same test, the WC/Co detonation-coated sample changed to a dark grey color, while the acid solution became a rose color due to cobalt leaching. The weight loss of the sample after 46 h and 40 min was ~0.3 g. The WC/Co detonation coating roughness changed from 0.10 to 0.41 µm Ra after testing in 20% HNO3 because of metal binder leaching.

In the oil and gas industry, use of the nanostructured CVD WC coating process opens the door to advanced designs for tools and components used in extreme environments with high wear and/or aggressive media, including applications for downhole and directional drilling, metal seated ball valves, and pumps that handle abrasive fluids. Typically the coating increases service life of critical parts by a factor of three.

More information on the CVD WC coatings can be found in CORROSION 2010 paper no. 10260, “Nano-structured CVD Tungsten Carbide Coating Protects Against Wear and Corrosion,” by Y.N. Zhuk.

Contact Yuri Zhuk, technical director, Hardide Coatings—email: yzhuk@hardide.com.

References

1 ASTM B117-16, “Standard Practice for Operating Salt Spray (Fog) Apparatus” (West Conshohocken, PA: ASTM, 2016).

2 NACE TM0177-2016, “Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments” (Houston, TX: NACE International, 2016).

3 ASTM G39-99(2016), “Standard Practice for Preparation and Use of Bent-Beam Stress-Corrosion Test Specimens” (West Conshohocken, PA: ASTM, 2016).